Method for channel steel high-temperature straightening

A technology of straightening and channel steel, which is applied in the field of metal material processing, can solve the problem of low energy consumption, achieve the effects of reducing straightening force, eliminating straightening blind spots, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The method for the channel steel high-temperature straightening provided by the present embodiment may further comprise the steps:

[0021] (1) Design of straightening pass;

[0022] (2) Use the straightening pass to straighten the waist deflection and outer edge slope of the channel steel before cooling after the rolling process;

[0023] (3) Conventional straightening after cooling, step (2) After straightening, the waist deflection and outer edge slope of the channel steel also meet the requirements of the national standard after cooling to room temperature, and conventional straightening does not need to be performed again on the waist deflection and outer edge slope Correction and straightening.

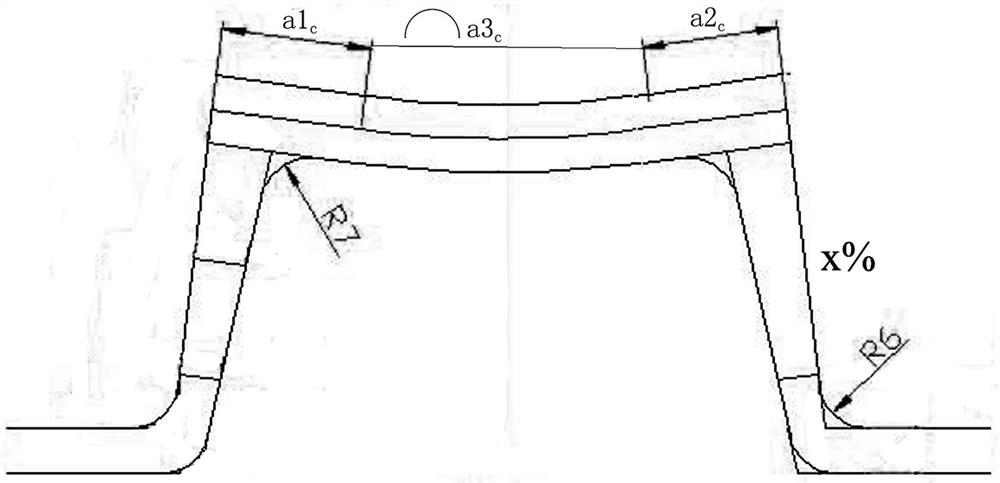

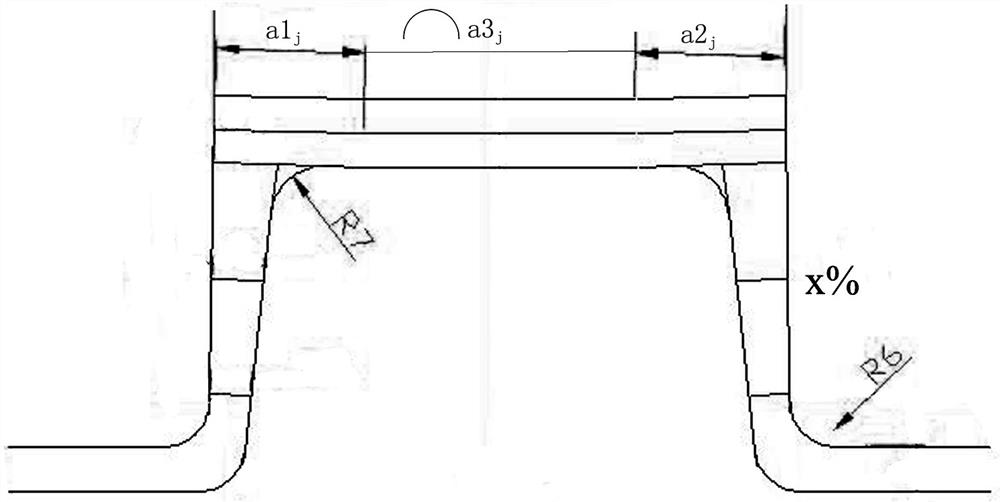

[0024] In this embodiment, the design of the straightening pass in step (1) is as follows figure 1 and 2 As shown, the center line of the waist of the straightening pass is equal to the center line of the waist of the finished pass, the thickness of the waist of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com