The control method of the collision buffer system of the hydraulic cylinder of the pusher

A hydraulic cylinder and buffer system technology, applied in the field of hydraulic cylinders, can solve problems such as inability to play a buffer role, slow response of fixed pressure relief valves, etc., and achieve the effect of improving the effect of buffering and energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

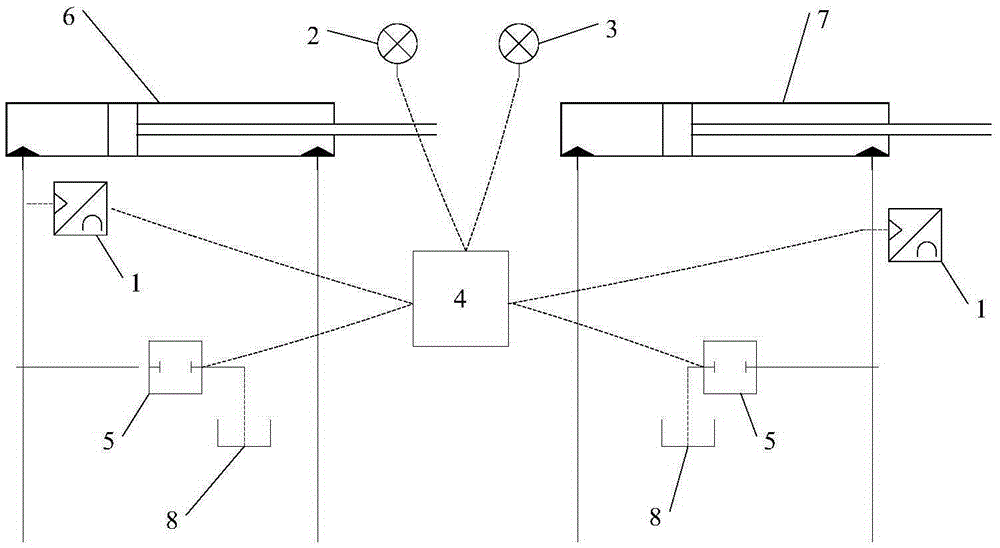

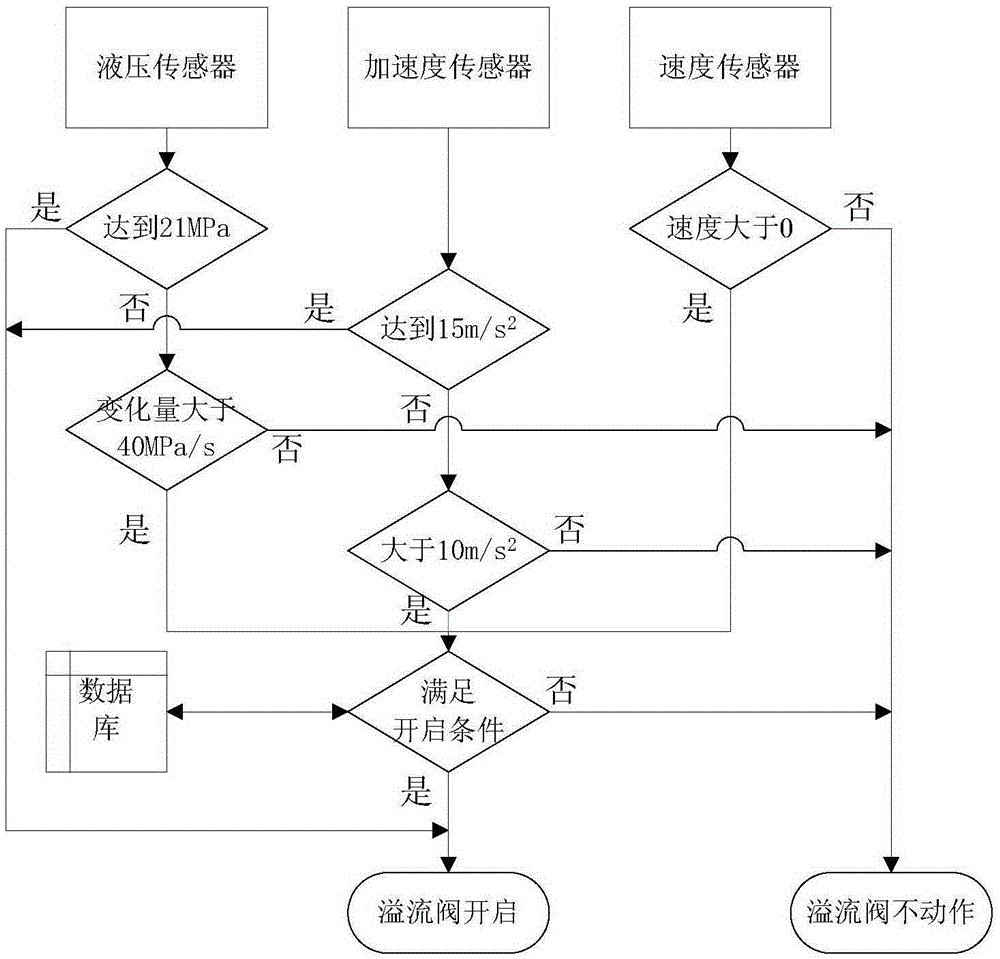

[0020] Such as figure 1 As shown, in the hydraulic cylinder collision buffer system provided by the embodiment of the present invention, the system takes the test data of the hydraulic sensor 1, the acceleration sensor 2, and the speed sensor 3, and through the judgment of the controller 4, realizes When the electromagnetic overflow valve 5 is opened, the electromagnetic overflow valve 5 is connected to the fuel tank 8 . Considering the force condition during the collision, the lifting cylinder 6 hydraulic sensor is installed in the rodless chamber oil circuit, and the push rake cylinder 7 hydraulic sensor is installed in the rod chamber oil circuit.

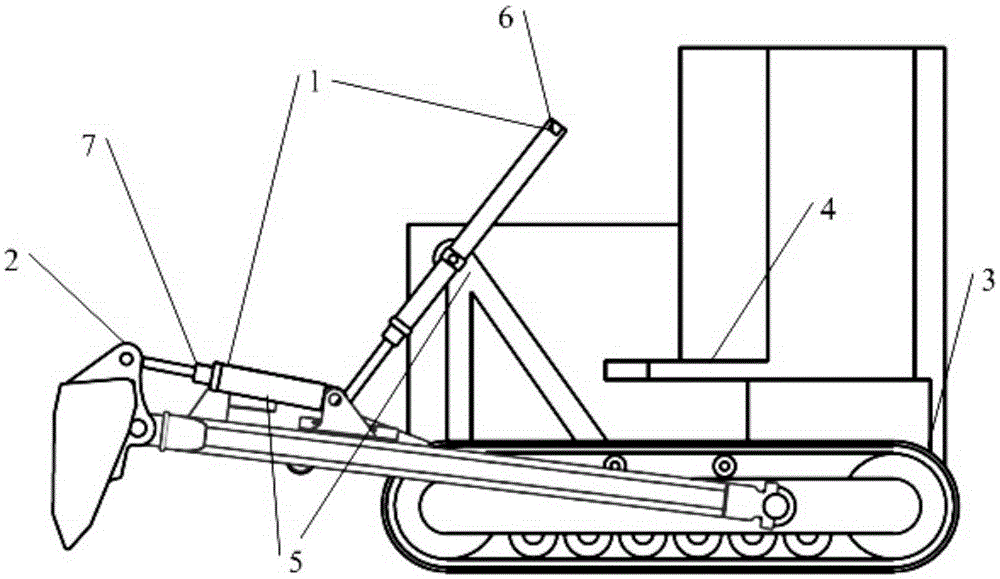

[0021] The installation location is as image 3 As shown, an acceleration sensor 2 is provided at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com