Die leakage detection device

A detection device and mold technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of mold affecting normal production, difficult to find water seepage, and difficult to find leak points, etc., to save test time and seal. Good, improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

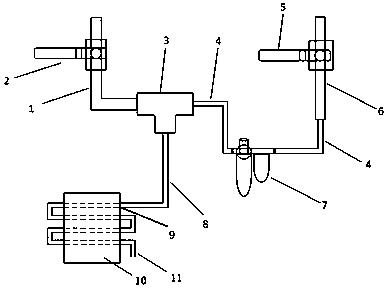

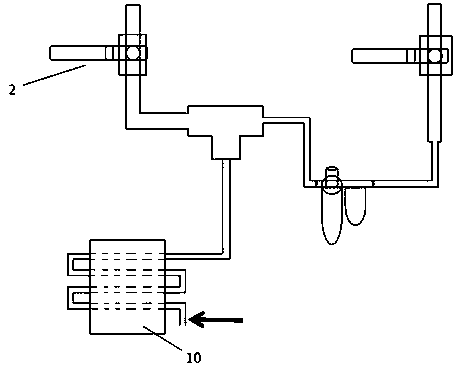

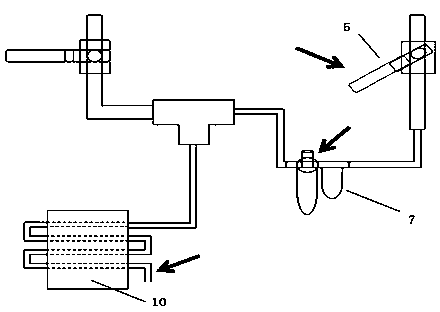

[0030] See figure 1 As shown, the mold leakage detection device of the present invention includes a water circuit mechanism, an air circuit mechanism, a three-way connection mechanism, and a mold access hole connection tube; the water circuit mechanism, air circuit mechanism, and mold access hole connection tube are respectively connected to the three-way connection mechanism One-way connection; water circuit mechanism includes water inlet pipe 1, water circuit switch valve 2; air circuit mechanism includes air supply pipe 4, air circuit switch valve 5, air supply device 6, air circuit pressure regulating device; mold access hole connecting pipe 8 and mold channel Connected. Among them, the three-way connecting mechanism can be a three-way 3; the air path pressure regulating device can be a pressure gauge 7, or it can be composed of a pressure gauge and an air filter; the three-way connection is made of PVC material or iron material with one inlet and two outlets The mold chann...

no. 2 example

[0033] Second embodiment Detecting mold water passage

[0034] See figure 1 As shown, the mold leakage detection device of the present invention includes a water inlet pipe 1, a water circuit switch valve 2, a three-way 3, an air supply pipe 4, an air circuit switch valve 5, an air supply device 6, a pressure gauge 7 and a mold access hole connecting pipe 8. ; The mold access hole connecting pipe is connected with the mold channel. The three-way pipe connector is made of PVC material or iron material with one inlet and two outlets.

[0035] The mold leakage detection method of the present invention includes the following steps:

[0036] Step 1. Connect the mold access hole connecting pipe with the mold water access hole, close the water circuit switch valve, and open the mold output hole; Step 2. Open the gas circuit switch valve, and adjust the output pressure range to 0.9- through the air circuit pressure regulator 1.1MPA, input high-pressure air flow to the mold channel to clean...

no. 3 example

[0037] The third embodiment detects the mold gas path

[0038] As in the second embodiment, where the detection method is different, the steps are:

[0039] Step 1. Connect the mold access hole connecting pipe with the mold gas access hole, close the water circuit switch valve, and open the mold output hole; Step 2. Open the gas circuit switch valve, and adjust the output pressure range to 0.9 through the gas circuit pressure regulator -1.1MPA, input high-pressure airflow to the mold channel to clean up the debris in the channel; step three, close the gas circuit switch valve, open the water circuit switch valve, after the mold channel is filled with water, close the mold output hole; step four, close the water circuit Switch the valve, open the gas circuit switch valve, adjust the gas circuit output pressure range to 0.7-1.5MPA through the gas circuit pressure regulator, and perform pressure leakage detection on the mold channel; step 5, detect the mold leakage, and obtain the det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com