Liquid crystal composition

A technology of liquid crystal composition and compound, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of insufficient effect and screen burn-in, and achieve the effect of less occurrence of screen burn-in and excellent high-speed response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

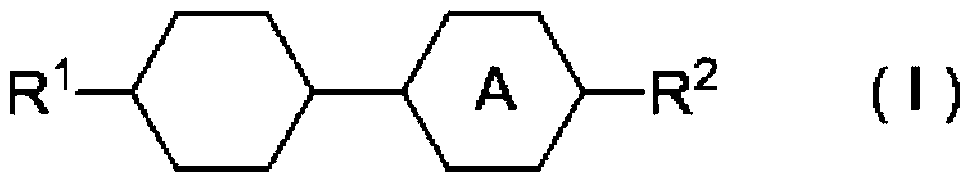

Method used

Image

Examples

Embodiment 1

[0157] A liquid crystal composition having the composition shown below was prepared, and its physical property values were measured. The results are shown in the table below.

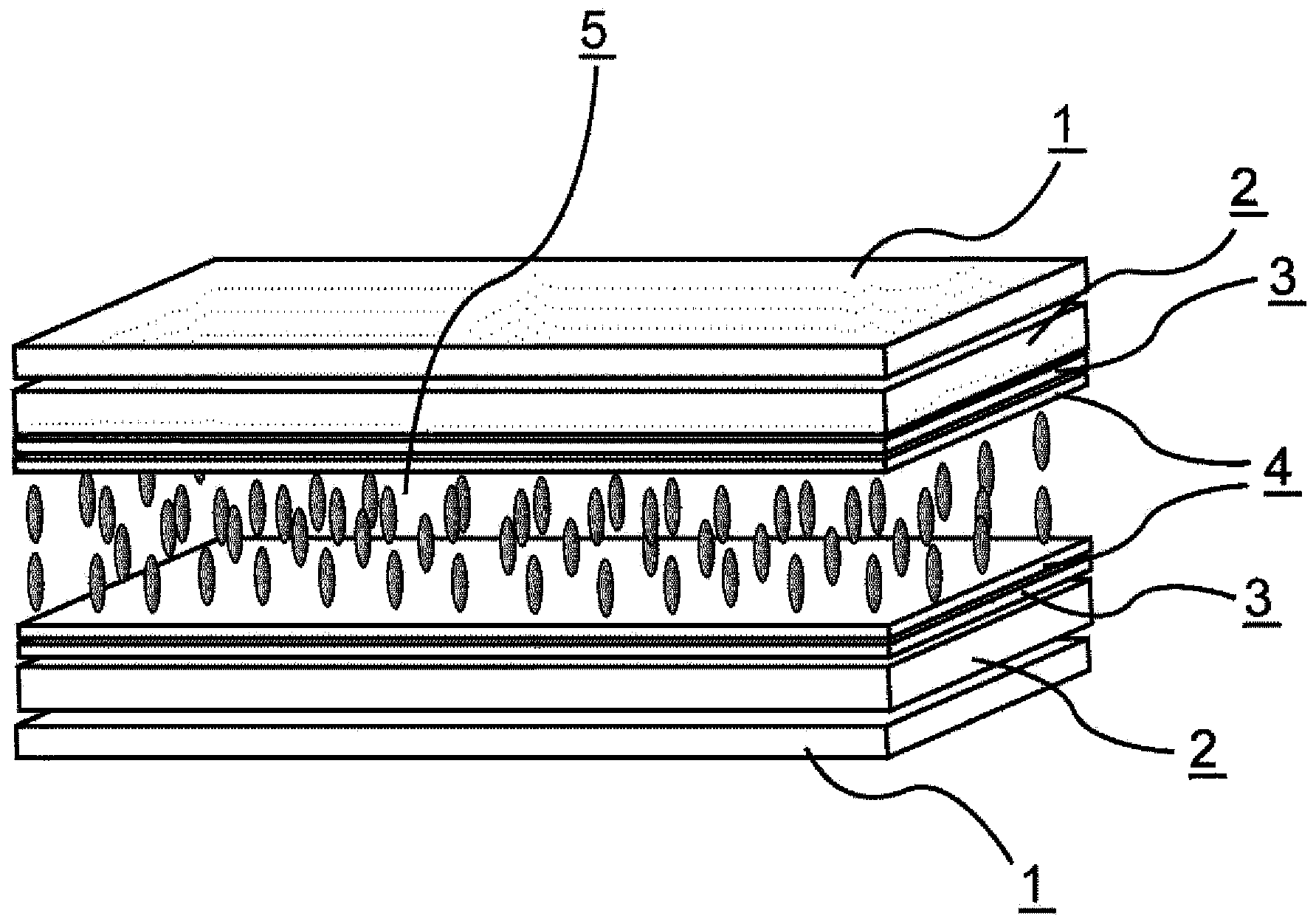

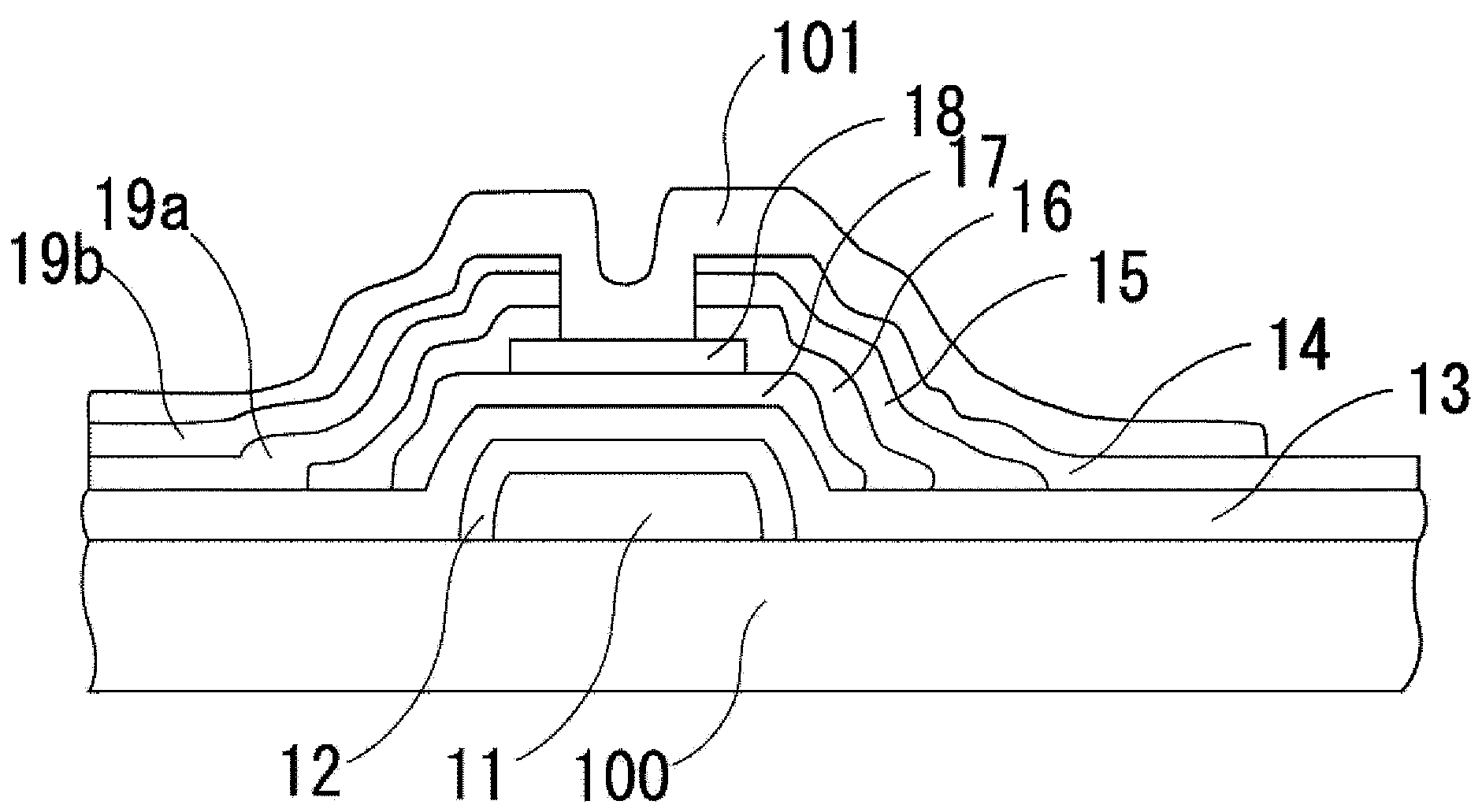

[0158] Use the liquid crystal composition of embodiment 1, make figure 1 The VA liquid crystal display element shown. This liquid crystal display element has an inverse stagger type thin film transistor as an active element. The injection of the liquid crystal composition was performed by a dropping method, and evaluations of burn-in and drop marks were performed.

[0159] In addition, the symbol on the right side of content is description of the abbreviation of the said compound.

[0160] Example 1

[0161]

[0162] [Table 1]

[0163] T NI / ℃

[0164] It can be seen that the liquid crystal composition of Example 1 has a liquid crystal layer temperature range of 81° C. which is practical as a liquid crystal composition for TV, has a large absolute value of dielectric constant aniso...

Embodiment 2 and 3

[0166] A liquid crystal composition having the composition shown below was prepared, and its physical property values were measured. The results are shown in the table below.

[0167] Using the liquid crystal compositions of Examples 2 and 3, a VA liquid crystal display element was produced in the same manner as in Example 1, and evaluations of burn-in and drop marks were performed, and the results showed excellent evaluations as shown in the table below.

[0168] [Table 2]

Embodiment 2 Embodiment 3

[0170]

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com