Solvent purifier for pretreatment of gelling

A purification device and solvent technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of reducing the frequency and time of heating incinerators, reducing the frequency of glue scraping in pipe valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

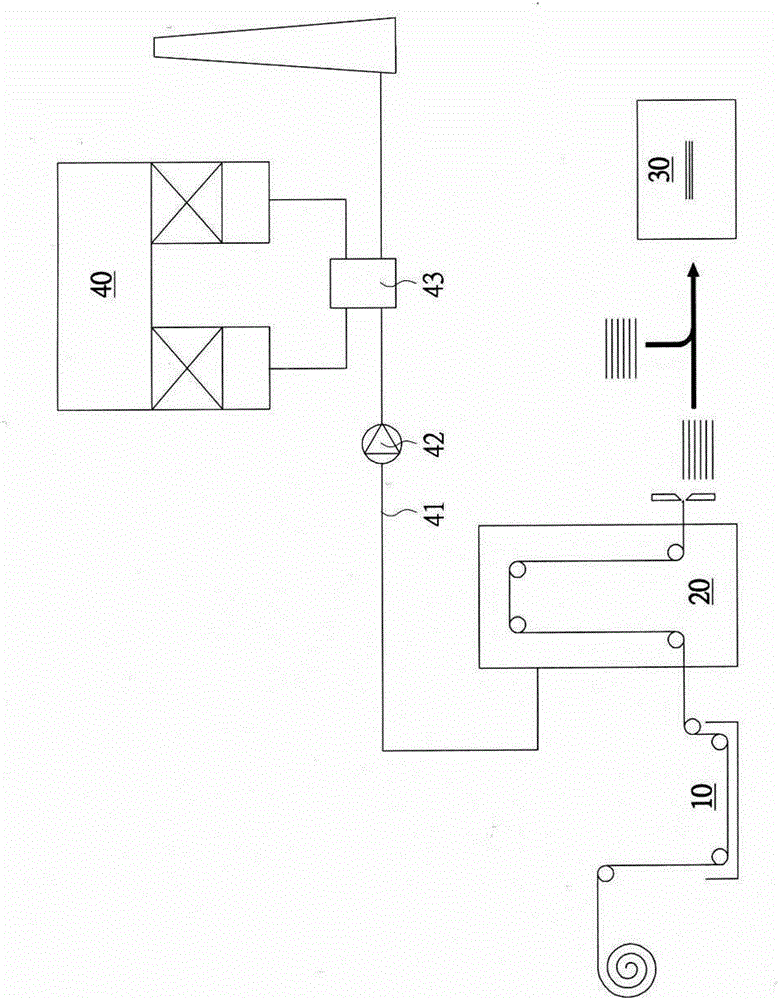

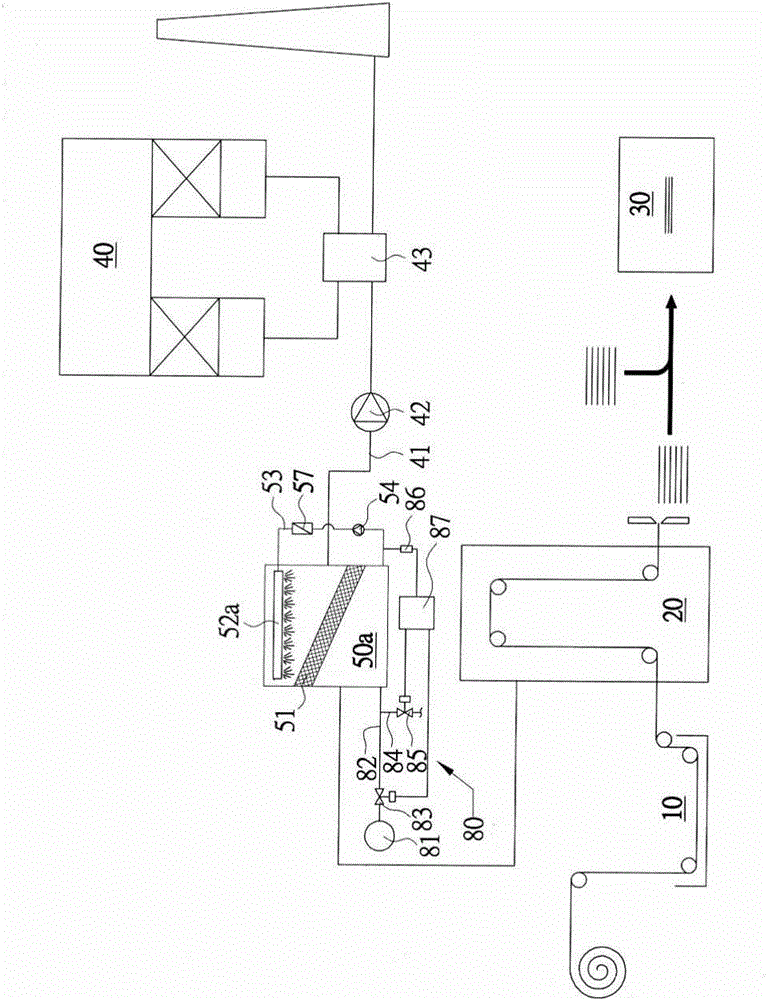

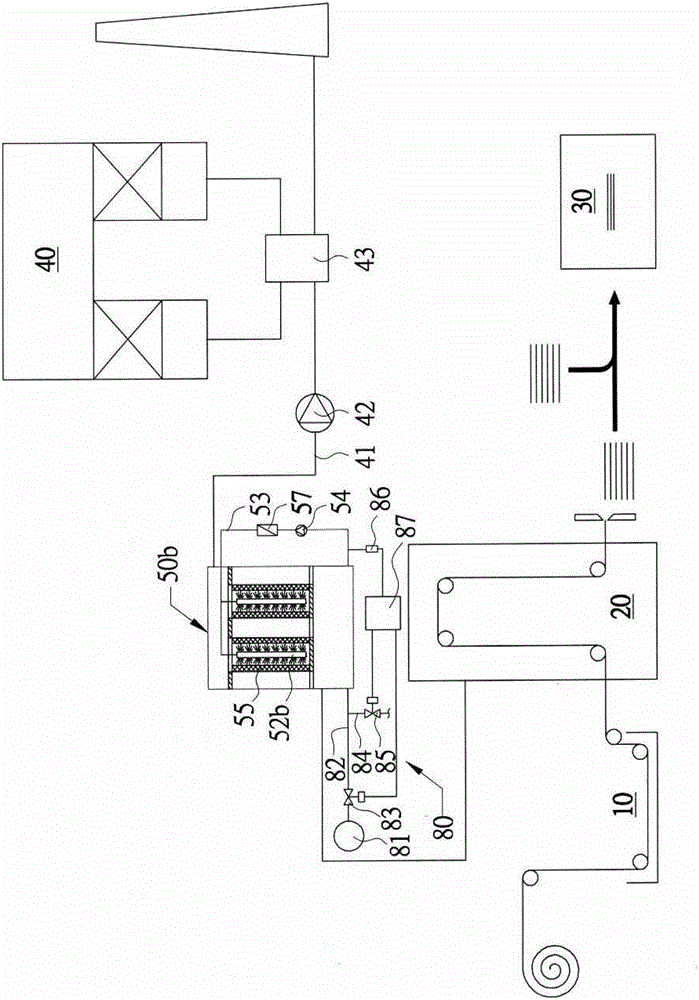

[0043] First, see the " figure 2 ”, the first embodiment of the solvent purification device of the present invention includes: an incinerator 40, which can be a direct-fired incinerator (ThermalOxidizer, TO), a catalytic type incinerator (CatalyticThermalOxidizer, CTO) or a regenerative direct-fired incinerator Furnace (Regenerative Thermal Oxidizer, RTO); an air induction pipe 41, which connects the incinerator 40 and the dryer 20 for impregnation drying, and the air induction pipe 41 is provided with an air induction windmill 42 and an air induction damper 43; a filter device 50a, It is arranged on the air induction pipe 41 and is located upstream of the air induction windmill 42 and the air induction damper 43, and the filtering device 50a is provided with a sheet filter 51 and an emulsifier sprayer 52a, and the emulsifier sprayer 52a is connected The other end of the emulsifier supply pipe 53 is connected to the bottom of the filter device 50a, and the emulsifier supply p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com