Magnetic hinge

A magnetic and hinge technology, applied in the field of hardware parts, can solve problems such as no lubricated structure, rust, hinge wear, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment the present invention is further described:

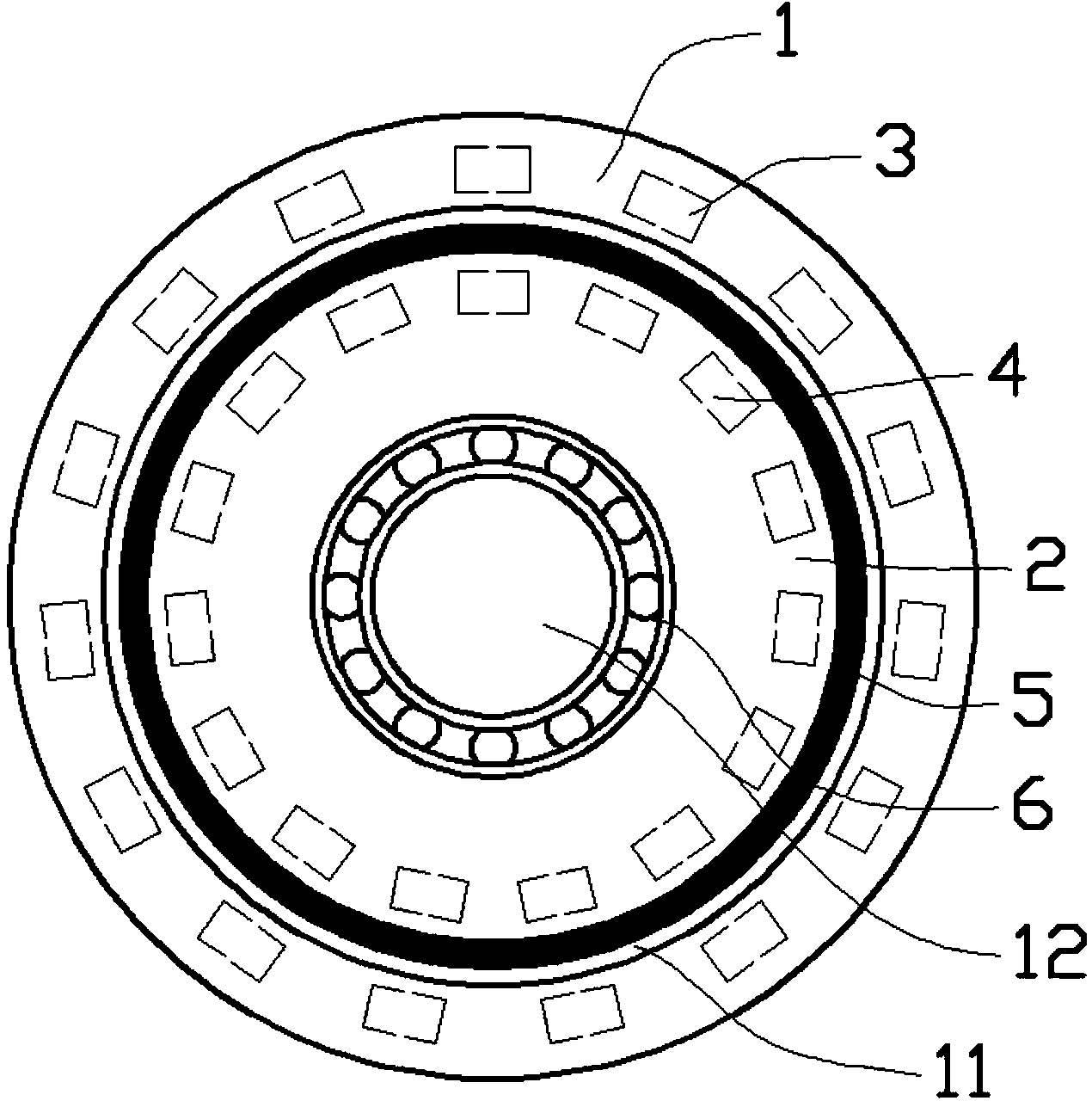

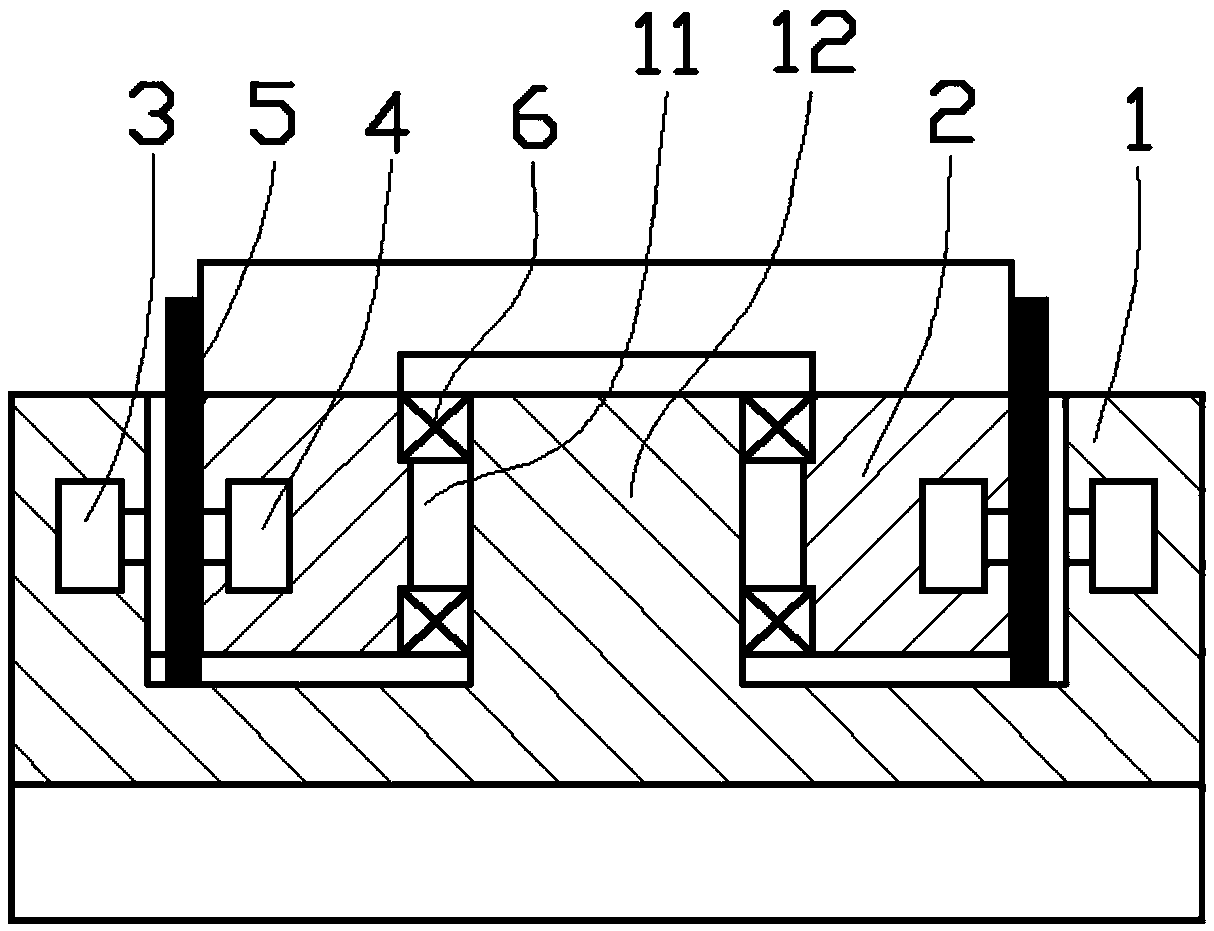

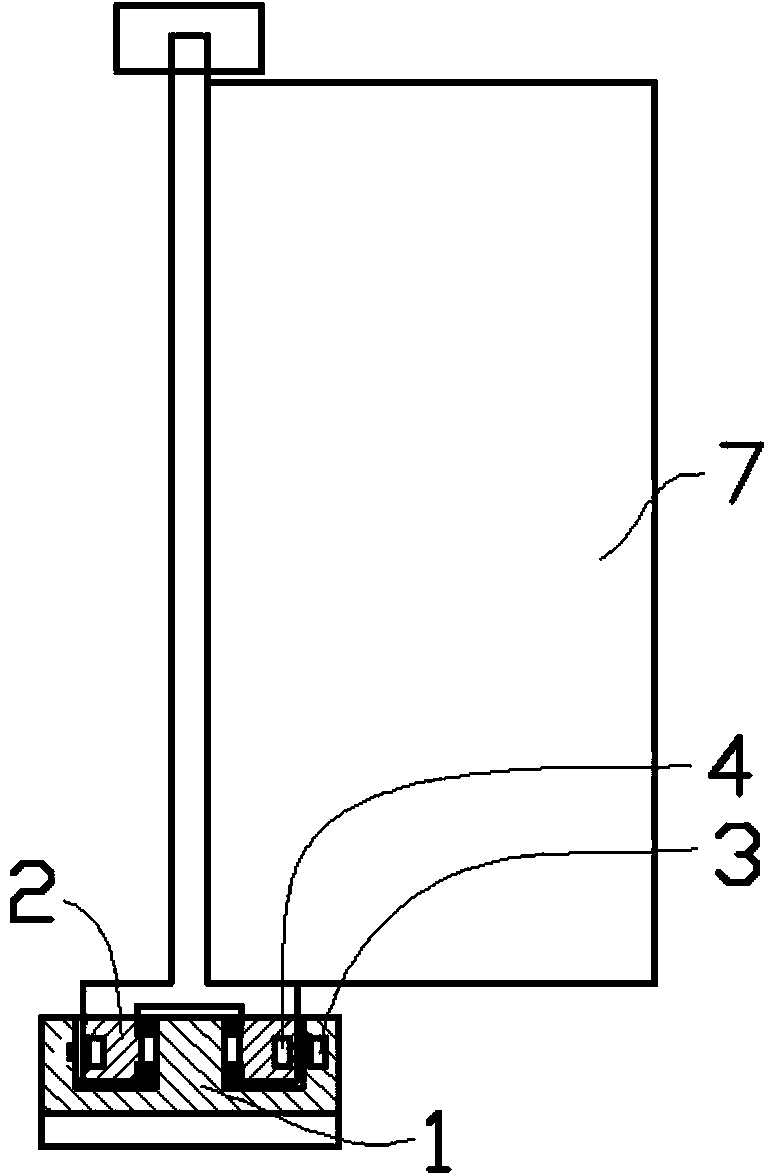

[0012] Such as figure 1 and figure 2 As shown in the embodiment, the magnetic hinge includes a fixed base 1 and a rotating base 2; the fixed base 1 is in the shape of a flat cylinder, and an annular groove 11 is designed on its upper surface, and the rotating base 2 is in the shape of a ring; On the outer wall of the fixed base 1 close to the annular groove 11, there are evenly distributed outer magnetic blocks 3 whose magnetic force points to the axial direction of the annular groove 11, and the inner part of the rotating seat 2 is equipped with a magnetic force facing the outer magnetic block at a position close to the outer wall. The inner magnetic block 4 of 3, the opposite surface of the outer magnetic block 3 and the inner magnetic block 4 adopt opposite magnetic poles;

[0013] This magnetic hinge is used to hinge the door parts, and its specific assembly method is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com