Clearance measurement device and method for bearing holding in shaft holding box of locomotive

A technology of measuring device and axle box body, which is used in mechanical clearance measurement, mechanical bearing testing, etc., can solve the problem of the deviation between the bearing clearance value and the actual value, and achieve the effect of accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in conjunction with accompanying drawing and specific embodiment:

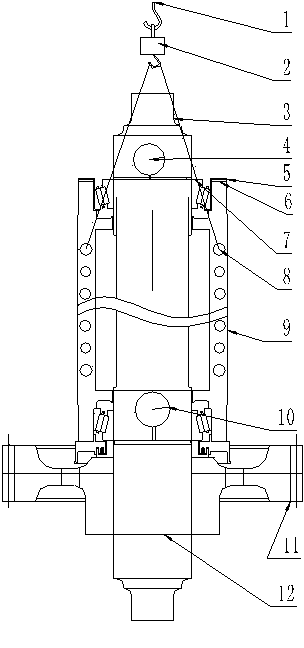

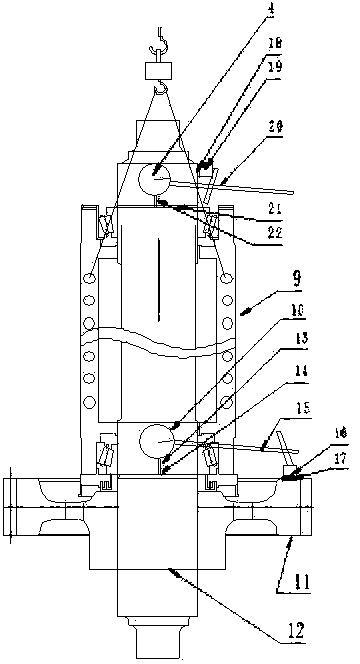

[0016] After the shaft-holding box is assembled, if figure 1 , use the hook of the crane to lift the electronic scale 2 equipped with the sling 3, and install the sling 3 on the two bolt holes 8 above the shaft holding box 9 to ensure that the shaft holding box is balanced during lifting. The hook of the car is directly above the axle 12, wipe the upper surface of the driven gear ring gear 17 clean with a lint-free towel, put the magnetic seat II16 of the magnetic seat dial indicator II10 on the driven gear ring gear 17, and adjust the The support rod II15 of the seat dial indicator II makes the measuring rod II14 of the magnetic seat dial indicator II10 vertically press against the gear end sub-box surface 14 of the shaft holding box body (the processing surface perpendicular to the shaft holding box motor mounting seat) , adjust the magnetic seat dial indicator II10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap