Hob mounting structure for raise boring machine

A technology for installation structure and raise drilling rig, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems affecting the operation accuracy of the hob disc, the harm of axial movement, and the high processing cost, so as to reduce the risk of loosening and fracture. , The effect of eliminating the axial assembly gap and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

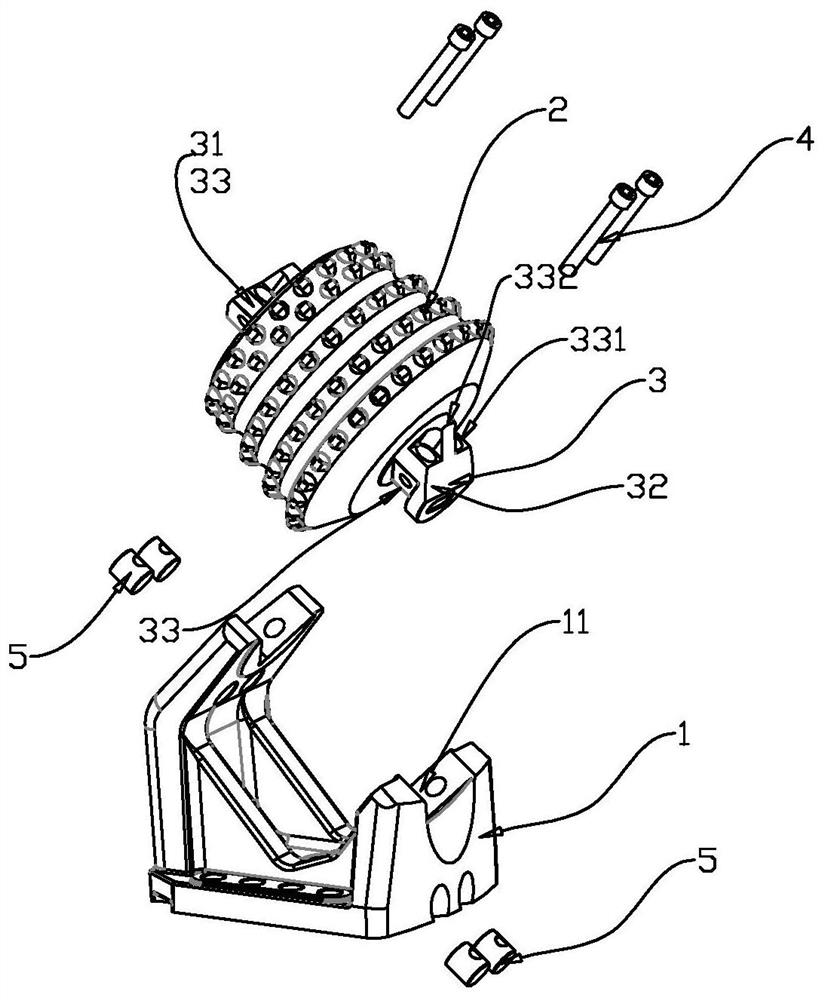

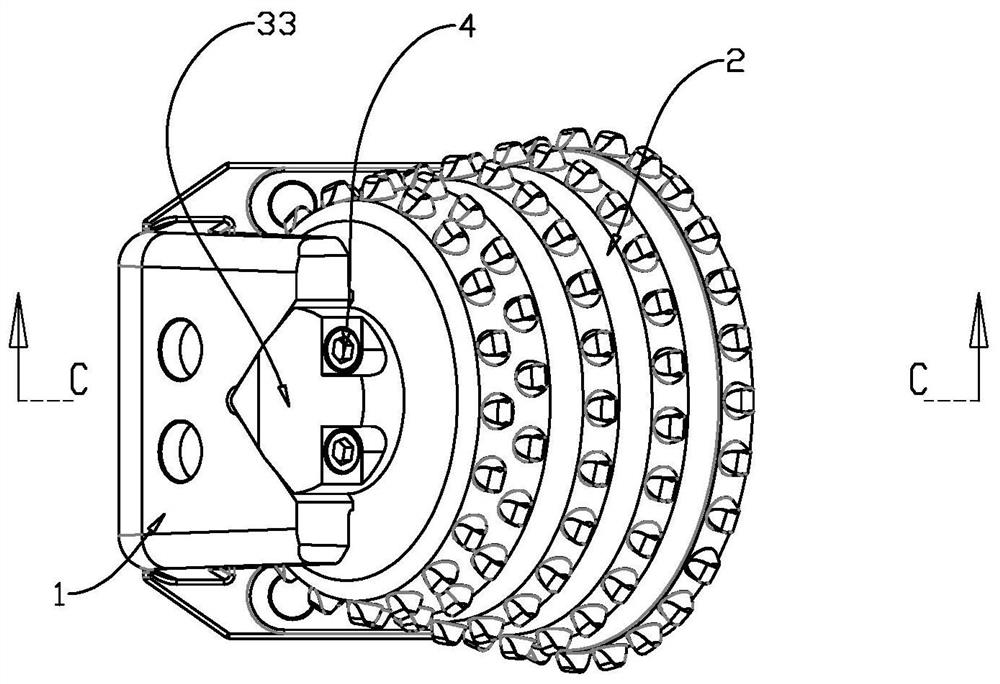

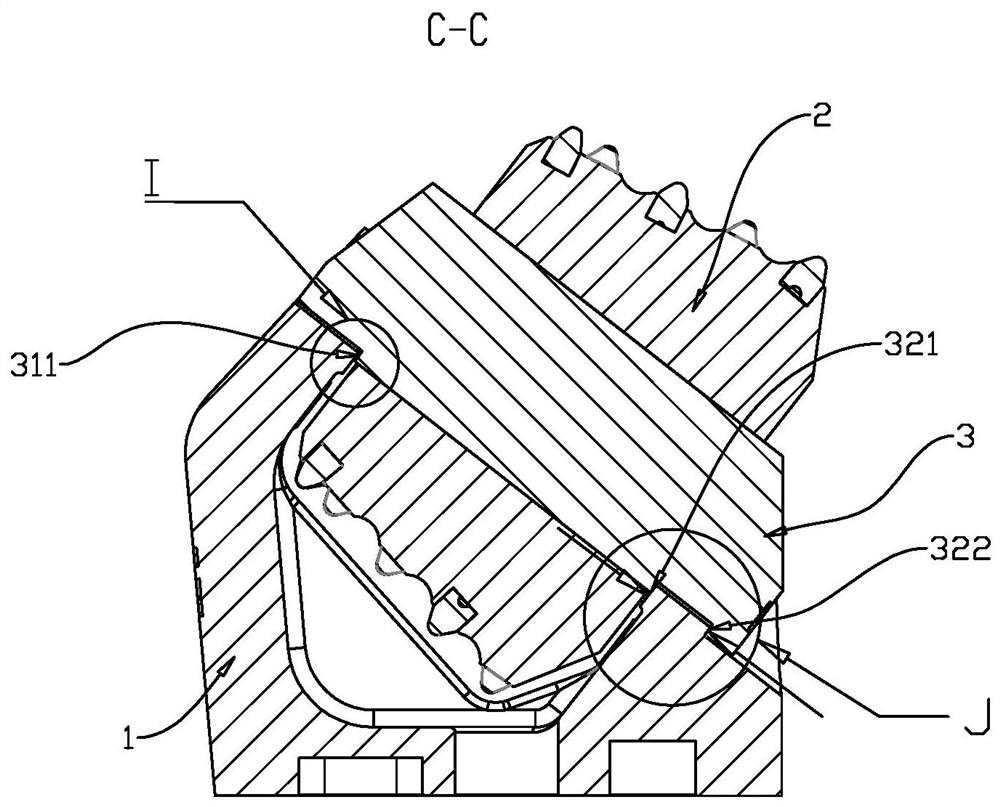

[0038] refer to Figure 1-Figure 5 , the present invention provides a hob installation structure for a patio drilling machine, comprising a hob holder 1, a hob 2 and a hob center shaft 3 for fixedly installing the hob 2, the hob center shaft 3 has a first end 31 and a second end end 32, and the first end 31 and the second end 32 are respectively provided with V-shaped parts 33, and the V-shaped parts 33 at both ends are respectively connected with the first shaft shoulder 311 and the second shaft shoulder 321 inwardly along the axial direction, and in The second end 32 is spaced apart from the second shoulder 321 and has a third shoulder 322 axially outward;

[0039]Both ends of the hob holder 1 are provided with V-shaped grooves 11 corresponding to the V-shaped portion 33, and both sides of the hob holder 1 have a first inner side wall 12 and a second inner side wall 13, and the The second inner side wall 13 is also provided with a third side wall 14 outward, and the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com