Cake material-mixing apparatus

A mixing device and cake technology, applied in the direction of mixing/kneading with a vertical installation tool, can solve the problems of not improving the mixing efficiency, consuming the power of the mixing device, and not achieving cutting effect, and improving the cutting and crushing effect. Ability, simple structure, and the effect of improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

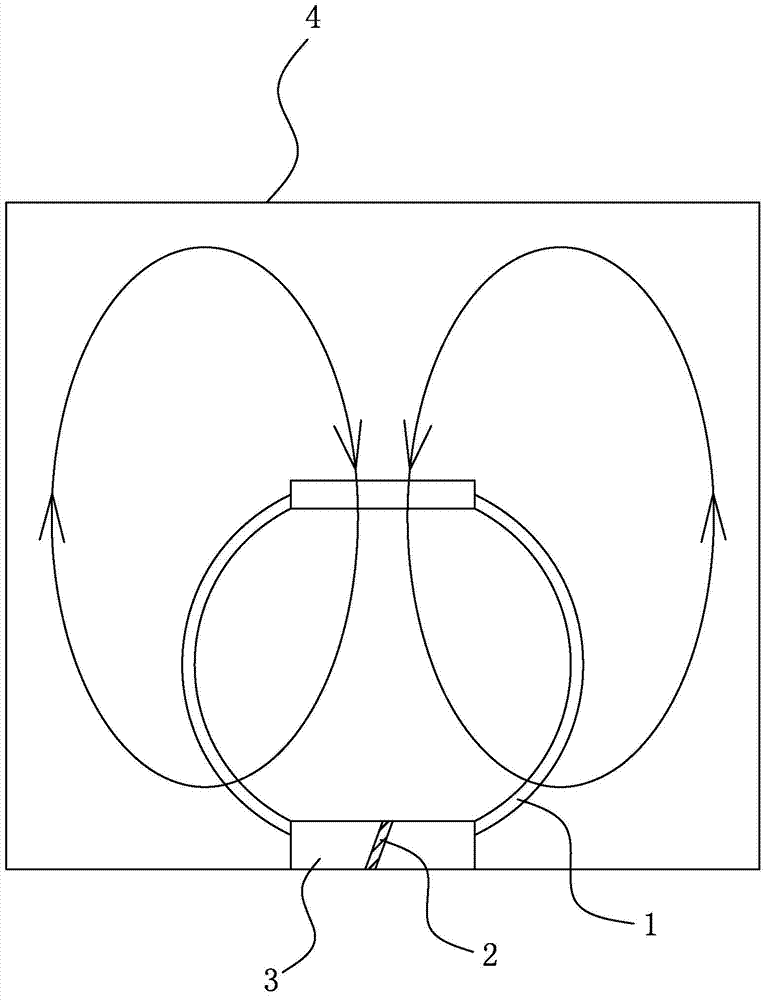

[0016] Embodiment one: see figure 1 , 2 As shown, a kind of cake mixing device, comprises bucket 4 and is arranged on the motor base below bucket 4, is provided with motor in the described motor base, and the output shaft of described motor and the mixer that is arranged in described bucket 4 The feeder is connected, and the mixer includes a blade-type stirring head at the bottom, and a spherical stirring head 1 arranged above the blade-type stirring head, and the blade-type stirring head is connected by a rotating base 3 connected to the output shaft of the motor And two blades 2 symmetrically arranged on the rotating base 3, the blades 2 are arranged obliquely, and the inclination angle is 45°.

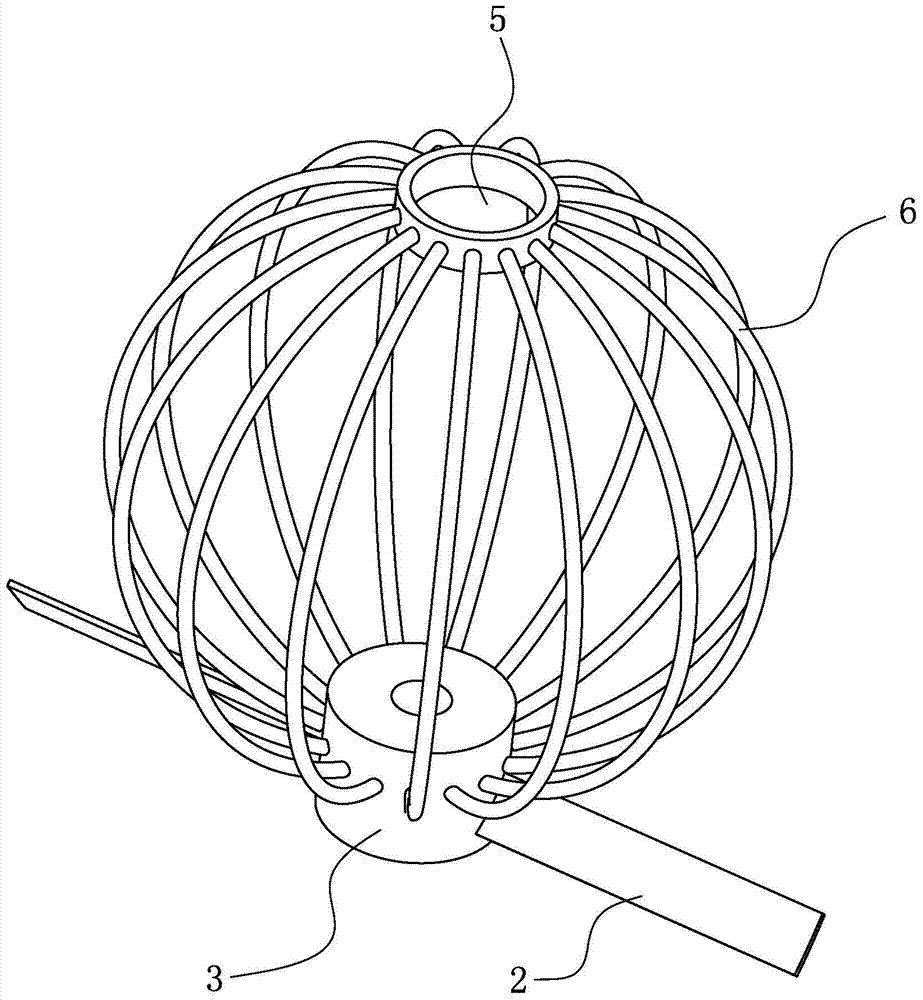

[0017] like figure 2 As shown, the spherical stirring head 1 is composed of a hollow sphere surrounded by a plurality of metal strips 6 in a warp arrangement, and the top of the spherical stirring head 1 is provided with an inflow port 5 communicating with the hollow sphere. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com