Protection device for filter element type high temperature iron removal filter

A protection device and filter technology, applied in the direction of filtration separation, chemical instruments and methods, separation methods, etc., can solve the problems affecting the life of filters and filter elements, filter element damage, large thermal stress, etc., to ensure safe operation, Extended service life, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

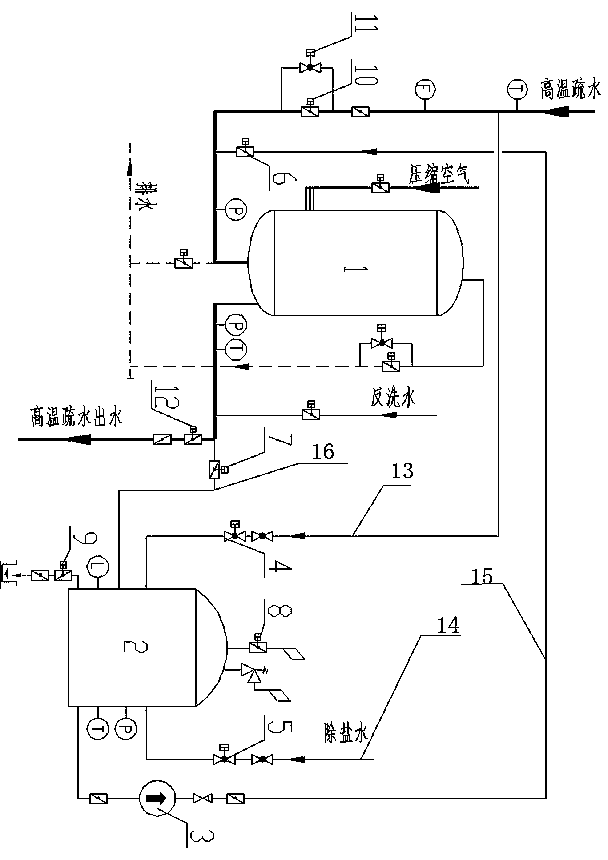

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0021] refer to figure 1 Shown is the temperature protection device of the filter element type high temperature iron removal filter 1 of the present invention. Including: a water tank 2, a first pipeline 13, a second pipeline 14, a third pipeline 15, a fourth pipeline 16, a hot water inlet valve arranged on the first pipeline 13, a desalinated water inlet valve arranged on the second pipeline 14 Water valve, the water pump 3 that is arranged on the 3rd pipeline 15 and the circulating water inlet valve, the water outlet valve that is arranged on the 4th pipeline 16, the first pipeline 13 connects the water inlet of water tank 2 to inject hot water to water tank 2, the second pipeline 14 is connected to the water inlet of the water tank 2 to inject demineralized water into the water tank 2. One end of the third pipe 15 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com