A special band sawing machine for bevel sawing of reel shaft and its use method

A reel shaft and band sawing machine technology, applied in the field of sawing machines, can solve the problems of wasting raw materials, long processing time, and difficult positioning, and achieve the effects of ensuring angular accuracy, ensuring mutual vertical accuracy, and improving the use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

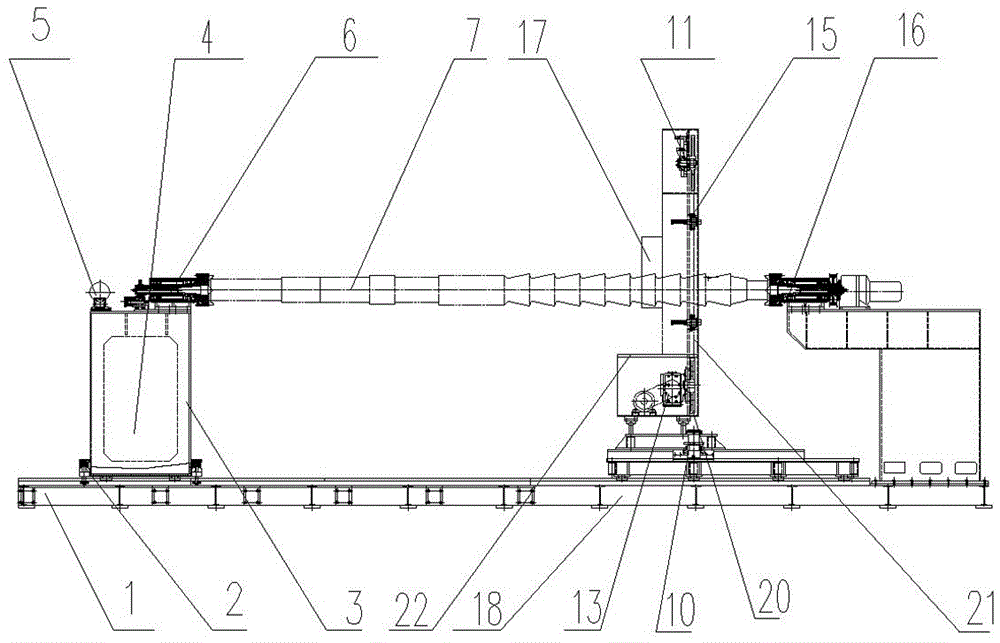

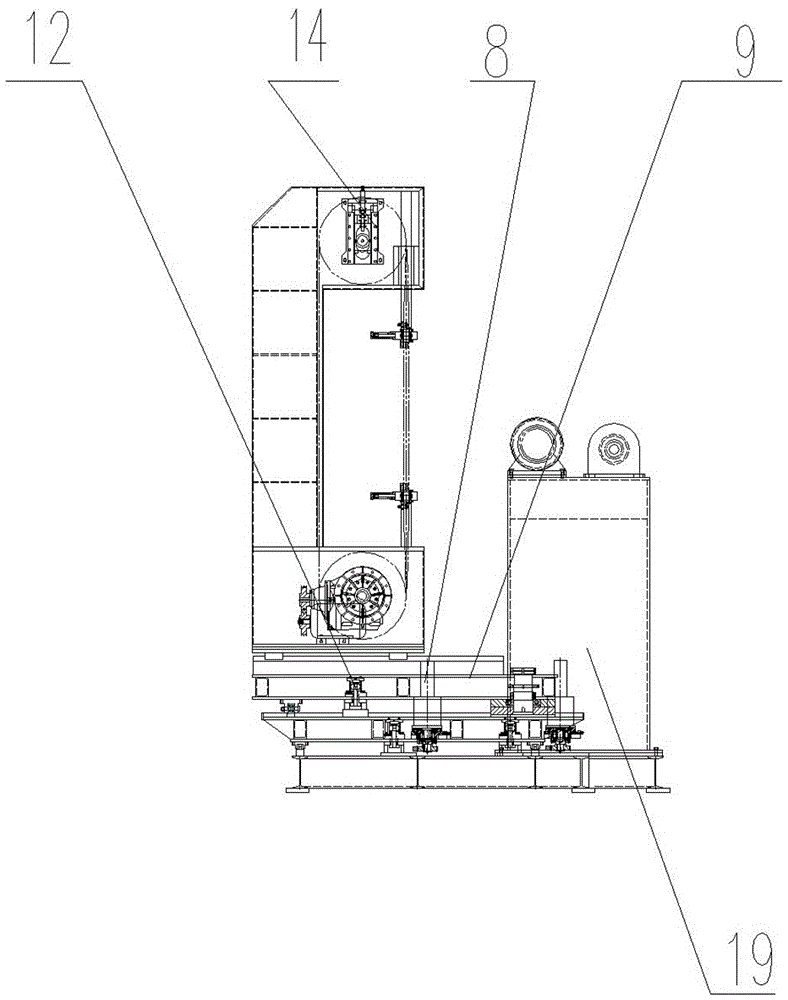

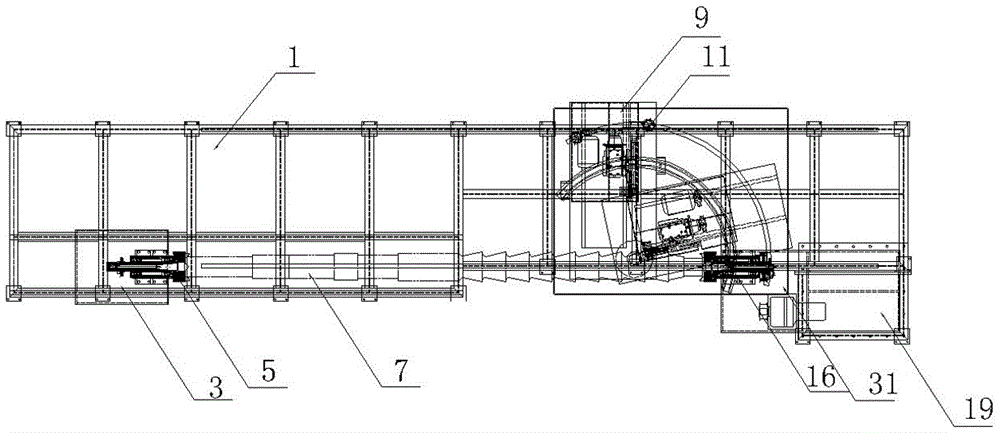

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

[0028] Such as Figure 1-3 As shown, a special band sawing machine for reel shaft bevel sawing includes a base 1 and a sawing machine body arranged on the base 1. The sawing machine body includes a sawing machine base 9, a saw frame 11 arranged on the sawing machine base 9, and a saw frame set on the saw frame. The main transmission system 13 on the saw frame 11, the saw frame hydraulic station 17, the cooling system 18 and the electrical system 19 arranged on one side of the saw frame 11, the sawing machine base 9 is slidably connected to the base 1, and the base 1 is provided with supporting workpieces at both ends. Matching fixed support seat 31 and movable support seat 3, the fixed support seat 31 and the movable support seat 3 are arranged on both sides of the sawing machine b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com