Bendable fiber rib

A fiber reinforcement and fiber technology, applied in the field of bendable fiber reinforcement, can solve the problems that composite fiber reinforcement cannot be replaced, fiber reinforcement cannot be bent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The specific implementation forms of the present invention will be described below in conjunction with the accompanying drawings.

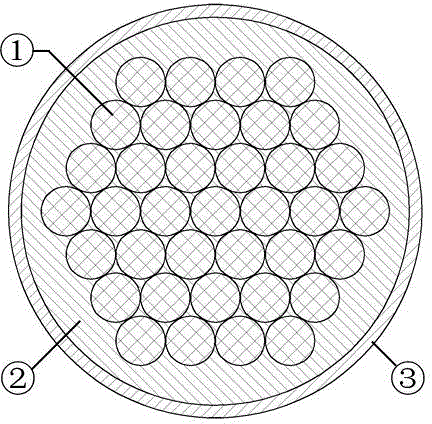

[0008] A bendable fiber reinforcement, which is characterized in that: the fiber thread ① uses glue that is elastic and bendable after solidification ② After soaking and solidification, the outermost layer is coated with a layer of glue that is rigid after solidification ③. The fiber ① is infiltrated and solidified with the elastic and bendable glue ② after solidification, and it must be ensured that the glue completely covers the fiber ①, and the fiber ① must not be exposed to the solidified glue. There is at least one kind of fiber filament ① in the same bundle of bendable fiber tendons.

[0009] This embodiment is only a typical embodiment of the present invention, and does not limit other embodiments, such as the type of fiber filaments, the thickness of the glue, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com