Parts mounting device and parts mounting method

A technology for mounting devices and components, applied in the direction of electrical components, electrical components, etc., can solve the problems of inability to achieve installation, electronic components do not fall, difficult to absorb electronic components, etc., to achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

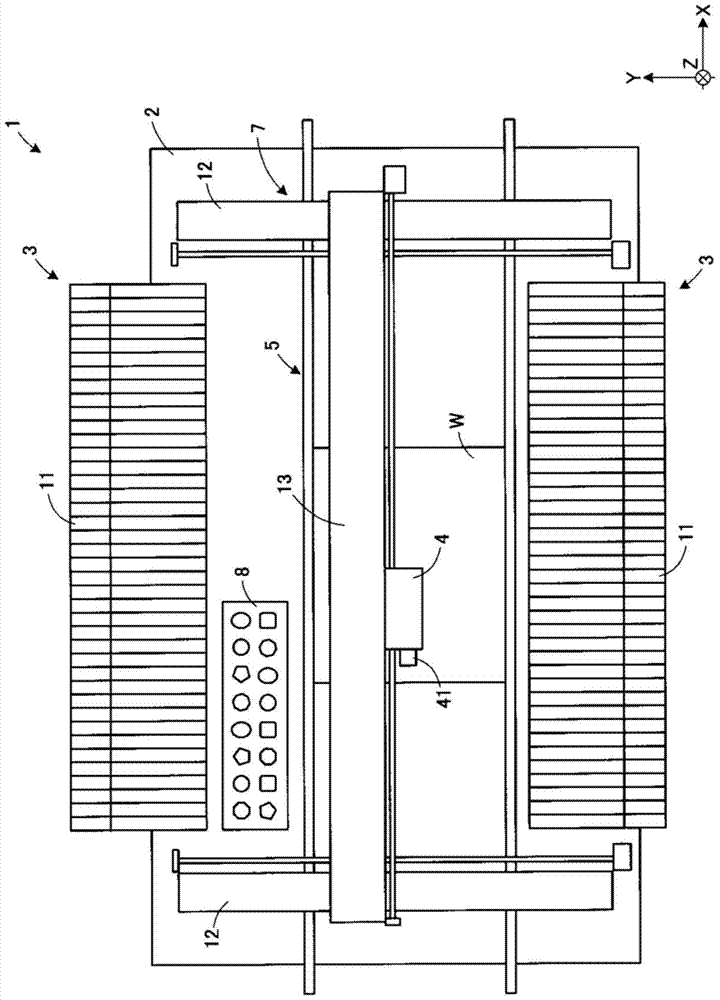

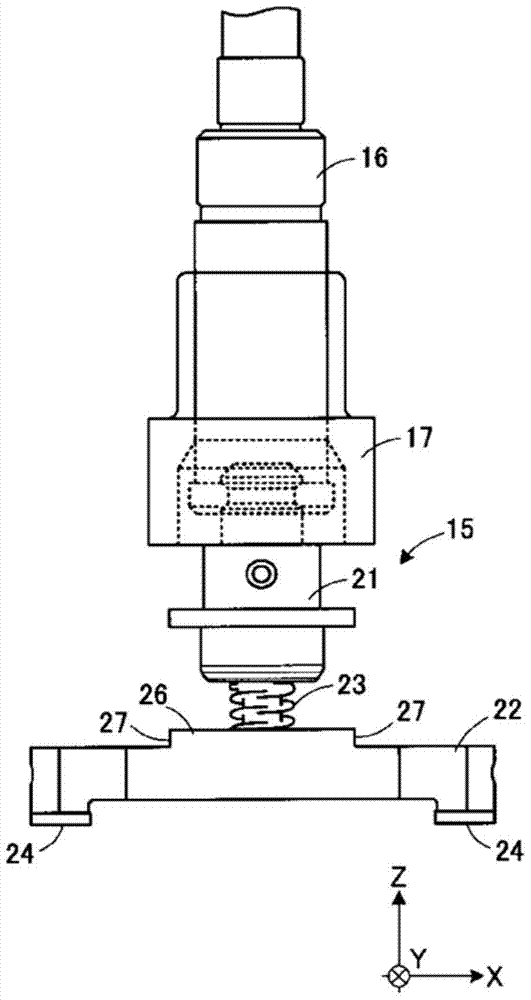

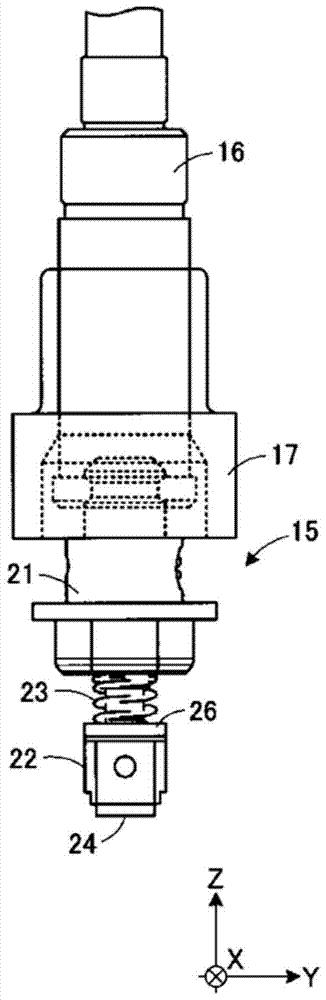

[0052] Below, refer to Figure 1 to Figure 5 , the first embodiment of the present invention will be described in detail. figure 1 It is a schematic plan view of the component mounting device according to the first embodiment. Fig. 2 is a plan view of the suction nozzle according to the first embodiment. image 3 It is a control block diagram of the component mounting device according to the first embodiment. In addition, although the case where the component mounting apparatus of this invention is used for mounting a shield case on a board|substrate is demonstrated below, it is not limited to this structure. The component mounting device of the present invention can also be used when mounting other electronic components.

[0053] Such as figure 1As shown, the component mounting apparatus 1 is configured to mount an electronic component 58 (see FIG. 4 ) supplied from a component feeder 3 serving as a component supply device onto a substrate W by using the mounting head 4 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com