Air heater

A technology of hot air device and hot core box, which is used in casting molding equipment, molds, cores, etc., can solve problems such as inability to accurately control temperature, affecting heat transfer effect and mold closing accuracy, and mold overheating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

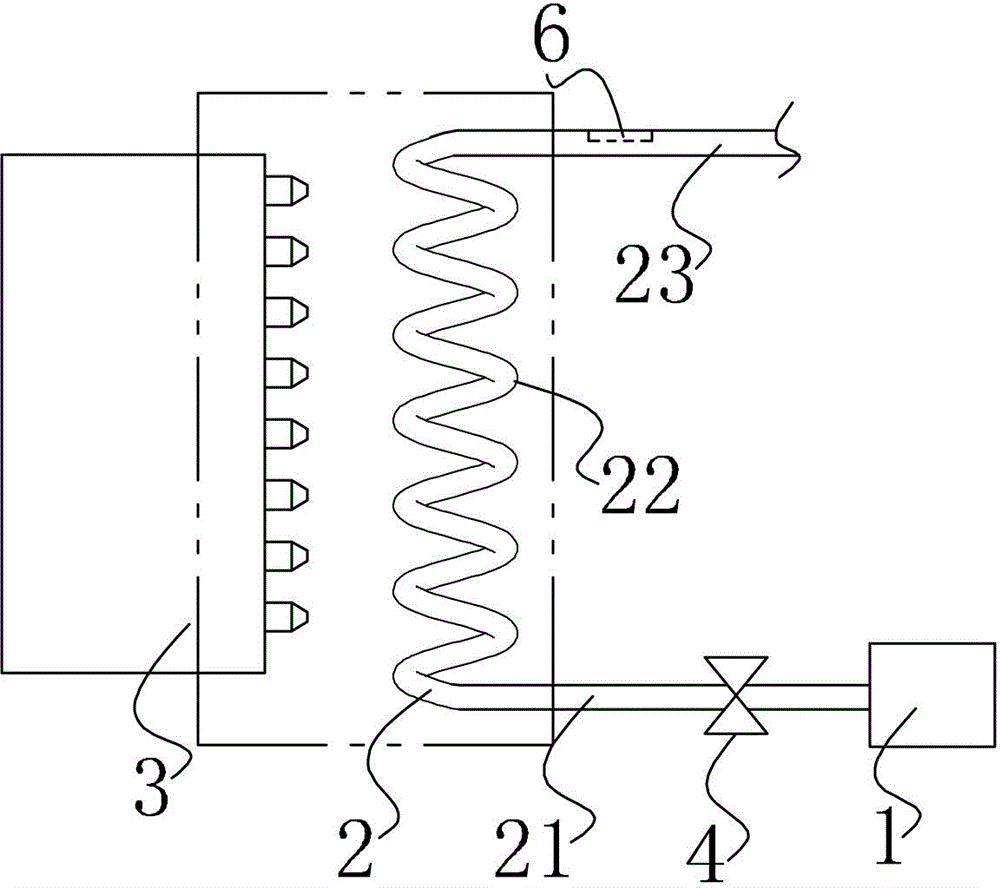

[0013] Embodiment 1: as figure 1 Shown: The hot air device is controlled by the central control system, including an air pump 1, an airflow pipe 2 and a burner 3. The airflow pipe 2 is divided into an air inlet section 21, a spiral section 22 and an air outlet section 23 according to the flow sequence of compressed air. The air inlet section 21 is connected with the air pump 1 , and a pressure regulating valve 4 is installed on the air inlet section 21 . The spiral section 22 of the air flow pipe 2 is located in the heat-insulating box, and the flame nozzle of the burner 3 is also installed in the heat-insulating box. Helical section 22 of tube 2 . The air outlet section 23 of the airflow pipe 2 is opposite to the sand injection port of the hot core box. After the sand is shot by the sand shooting machine, high-temperature compressed air is passed into the hot core box. A temperature sensor 5 is fixed on the inner wall of the air outlet section 23 of the airflow pipe 2 . Th...

Embodiment 2

[0015] Embodiment 2: The difference from Embodiment 1 is that a compressed air tank or a compressed air station is used to replace the air pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com