Equipment for quickly thawing frozen livestock foods

A technology for frozen food and livestock, applied in food processing, preservation of meat/fish by freezing/cooling, etc., can solve the problems of large energy waste, easy deterioration of food, low efficiency, etc., and achieves improved thawing efficiency, shortened thawing time, The effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

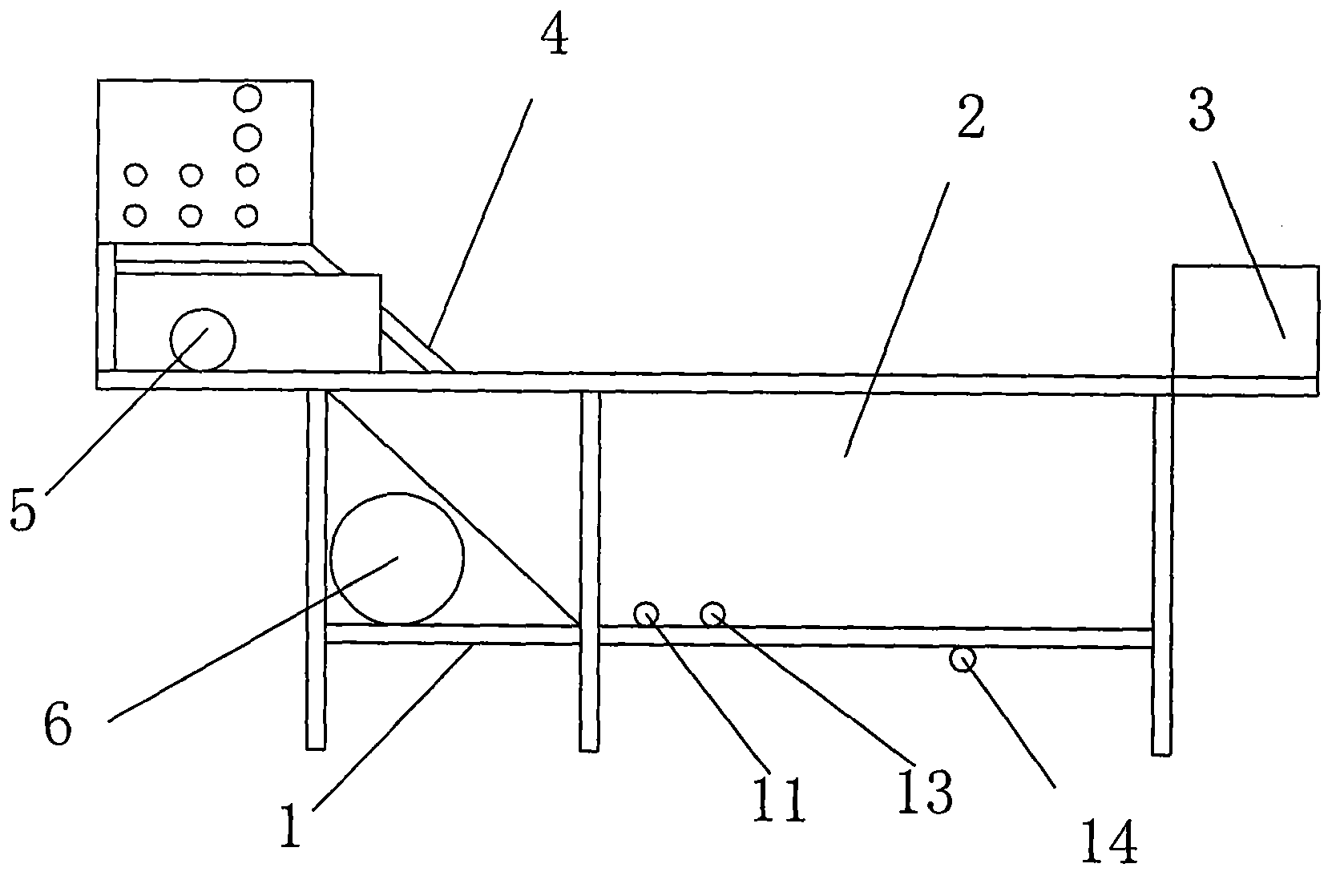

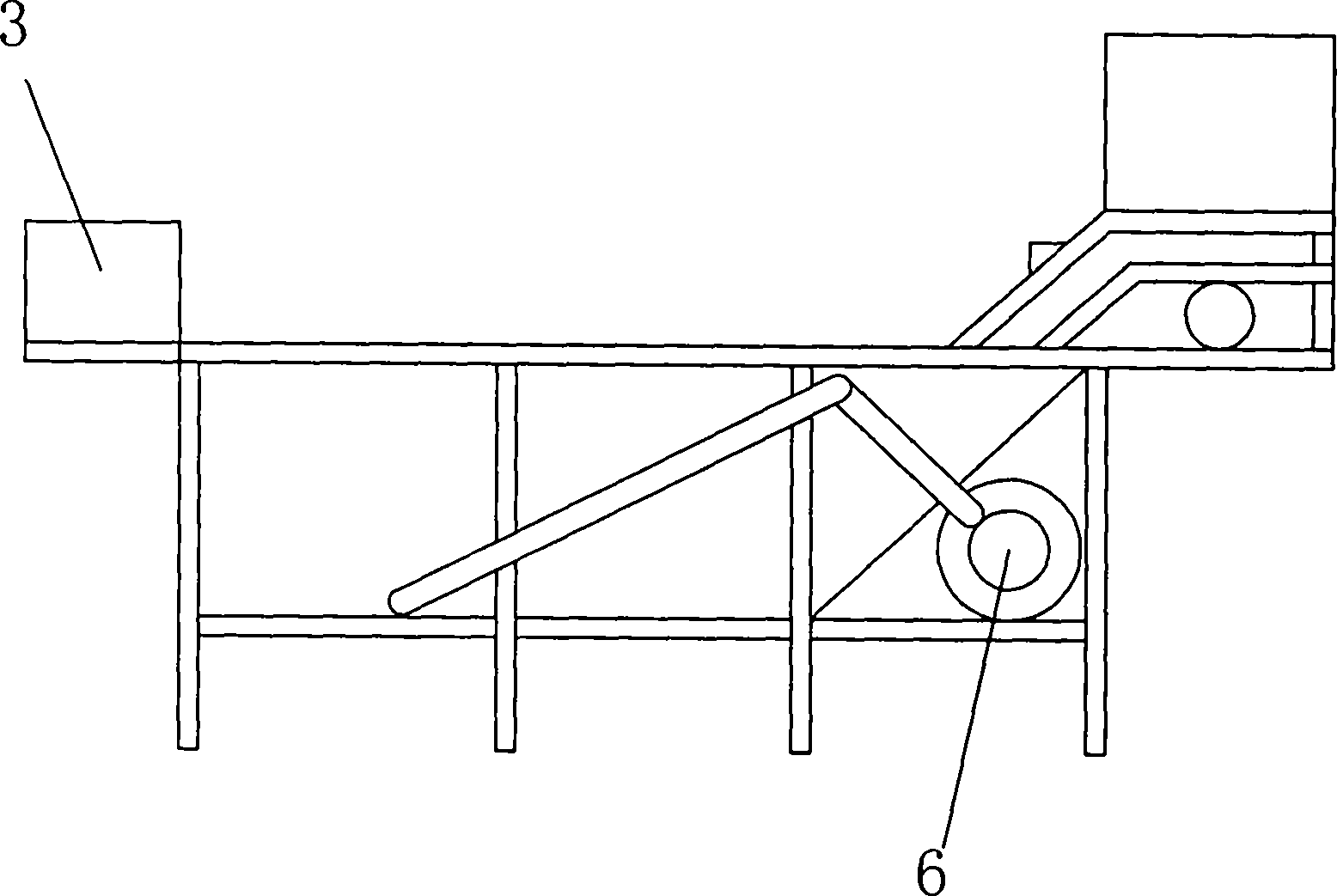

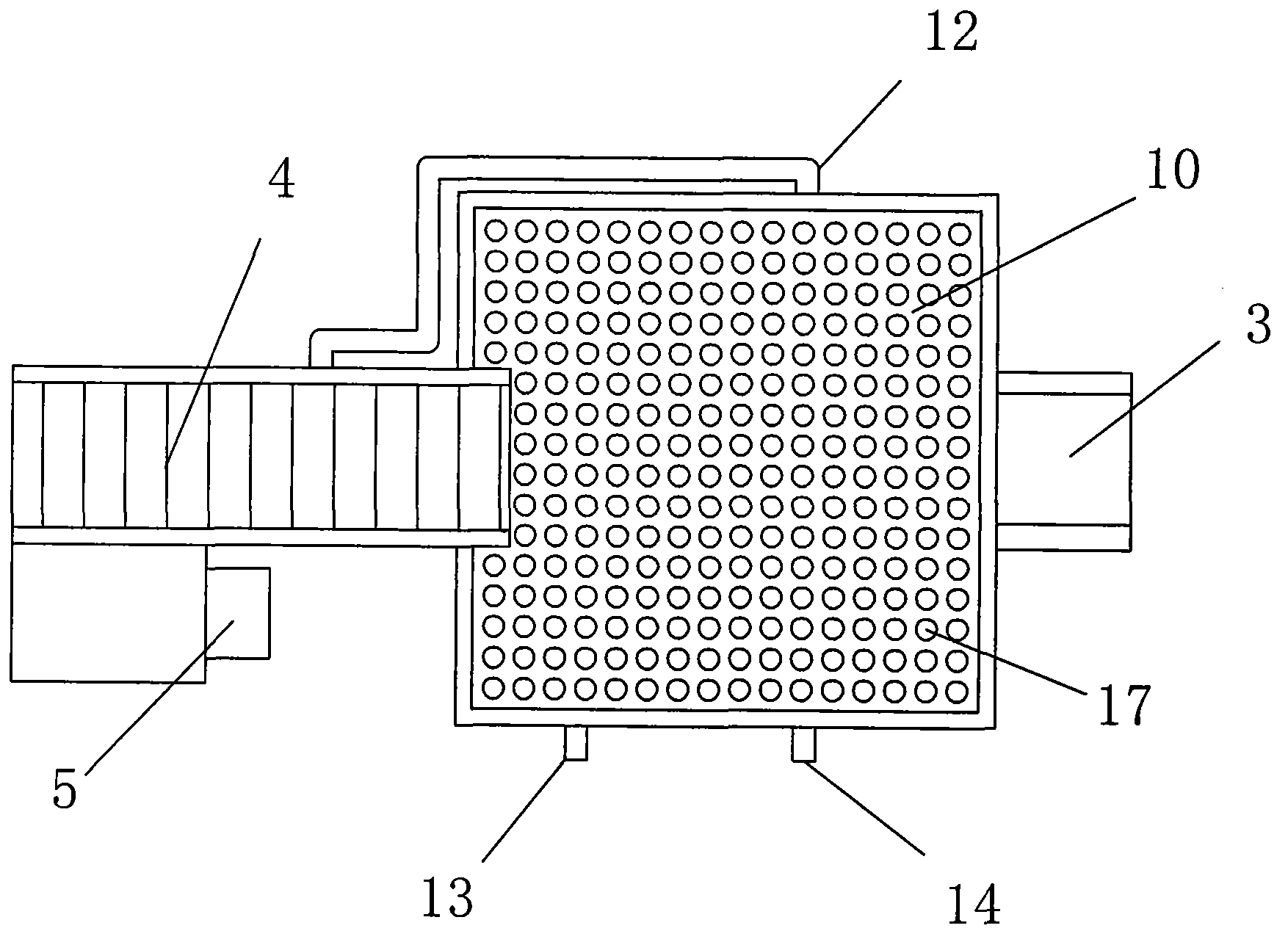

[0030] Such as Figure 1 to Figure 4 As shown, a quick thawing equipment for poultry frozen food includes a bracket 1 and a thawing pool 2, which is used for thawing duck meat, chicken meat, beef pieces, and pork pieces;

[0031] It also includes a feed port 3, a discharge chain 4, a motor 5, a fan 6, a compressed air pipeline 7, a hot air pipeline 8, a supporting steel bar 9, a mesh plate 10 and a temperature sensor 11; the thawing pool 2 is a square metal pool, The thawing tank 2 is arranged on the right part of the support 1, and the length × width of the thawing tank 2 is 2 × 2m; the feeding port 3 is arranged above the right side of the thawing tank 2, and the discharge chain 4 is arranged obliquely on the left side of the support 1 Above the upper part, the motor 5 is arranged on one side of the discharge chain 4, and the discharge chain 4 is driven by the motor 5; the fan 6 is arranged on the lower left side of the bracket 1; the temperature sensor 11 is arranged on the...

Embodiment 2

[0041] Such as Figure 4 to Figure 6 As shown, a quick thawing equipment for poultry frozen food includes a bracket 1 and a thawing pool 2, which is used for thawing duck meat, chicken meat, beef pieces, and pork pieces;

[0042] It also includes an air inlet 6, a compressed air pipeline 7, a hot air pipeline 8, a supporting steel bar 9, a mesh plate 10 and a temperature sensor 11; the thawing pool 2 is a square metal pool.

[0043] It also includes an electric hoist and a metal mesh frame (the electric hoist and the metal mesh frame are both prior art, not shown in the figure, and the structures of the two are well known and will not be described in detail), which are used for automatic loading and unloading of poultry frozen food in the thawing pool 2 The electric hoist is arranged on the top of the thawing pool 2, and the metal mesh frame is movably hung below the electric hoist. The metal mesh frame is used for bundling the frozen food of poultry and livestock. The metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com