Control method used for thawing plant

A control method and chamber technology, applied in the field of thawing, can solve problems such as loss of juice, uneven heating of ingredients, and damage to the quality of ingredients, so as to avoid energy consumption, avoid damage caused by long-term no-load work, and reduce failure rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

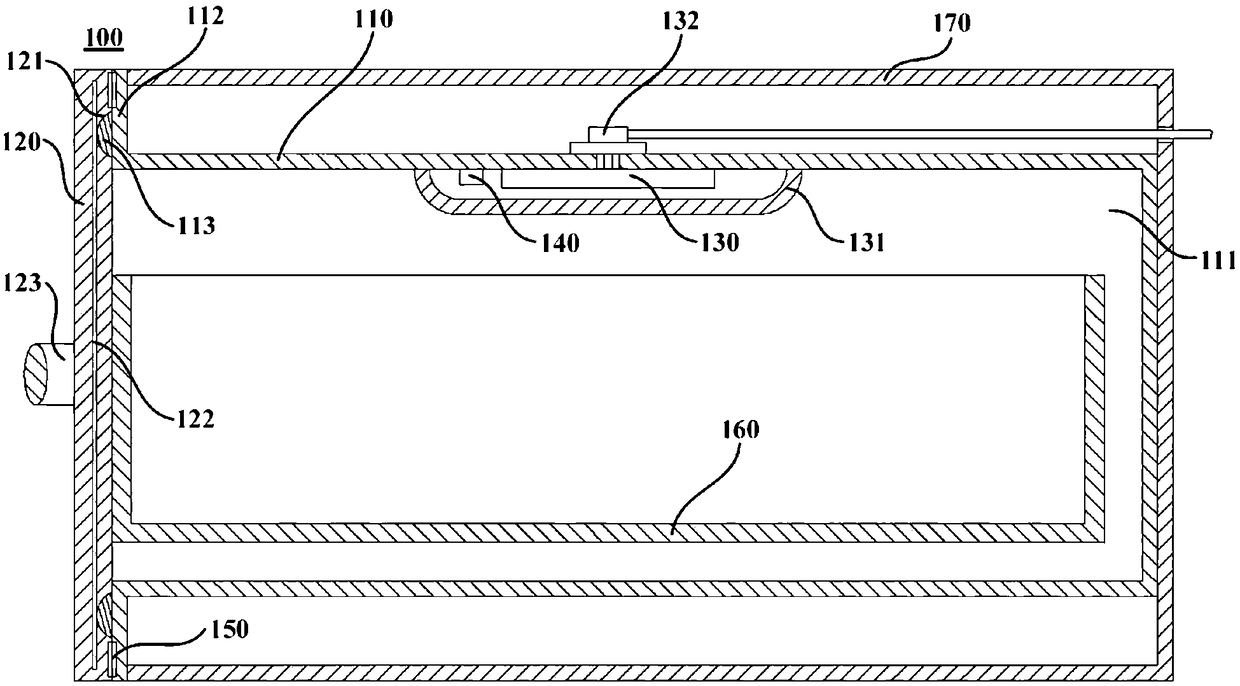

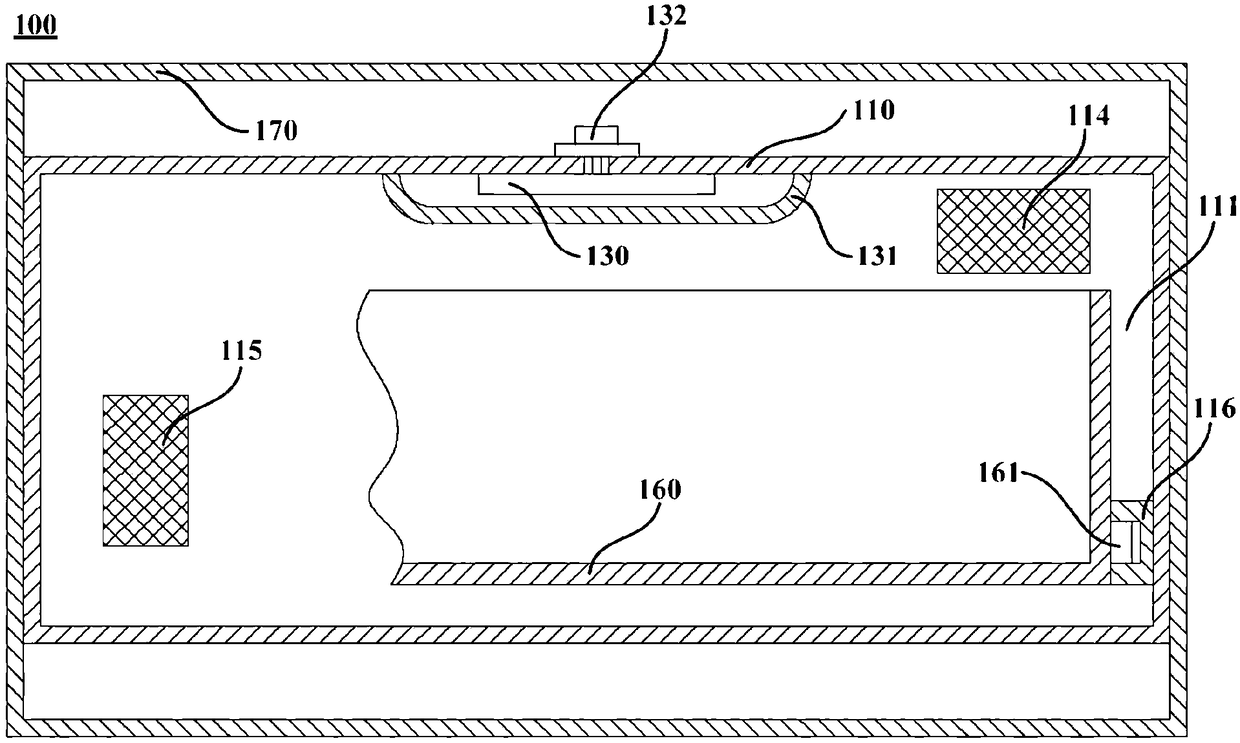

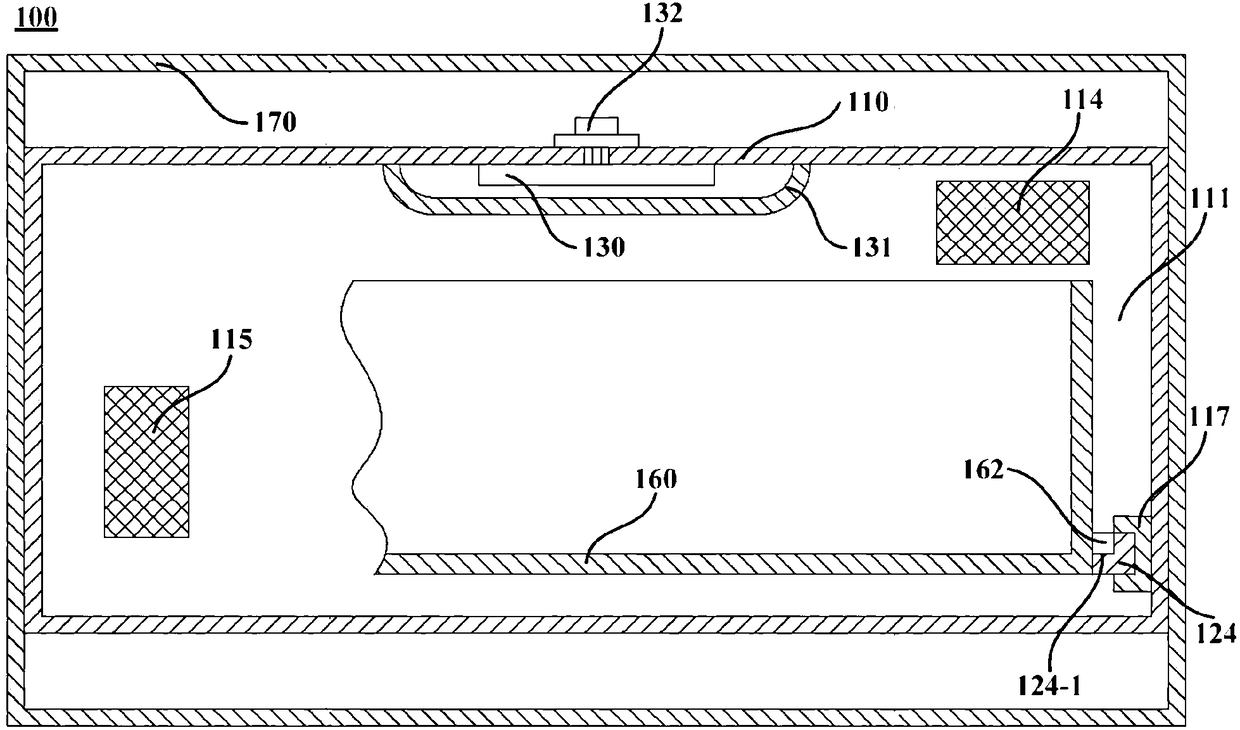

[0050] figure 1 It is a schematic cross-sectional view of the thawing device 100 according to an embodiment of the present invention. See figure 1 The thawing device 100 may include a cylinder 110, a device door 120, a radio frequency generating module 190, and a radio frequency antenna 130. Specifically, the barrel 110 defines a thawing chamber 111 for placing the object to be processed. The device door 120 can be arranged at the access opening of the thawing chamber 111 for opening and closing the access opening of the thawing chamber 111. The radio frequency generating module 190 may be configured to generate radio frequency signals (generally referring to radio frequency signals with a frequency of 300 KHz to 300 GHz). The radio frequency antenna 130 may be a rectangular metal sheet. The radio frequency antenna 130 may be composed of a transmitting antenna and a receiving antenna arranged side by side along the lateral direction or the front-rear direction of the thawing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com