Wet type electric precipitation device and method for removing fine particulate matters in smoke desulfurized by wet process

A wet electrostatic precipitator and wet desulfurization technology, which is applied in electrostatic separation, electrode cleaning, external electrostatic separator, etc., can solve the problems of poor dust removal effect and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

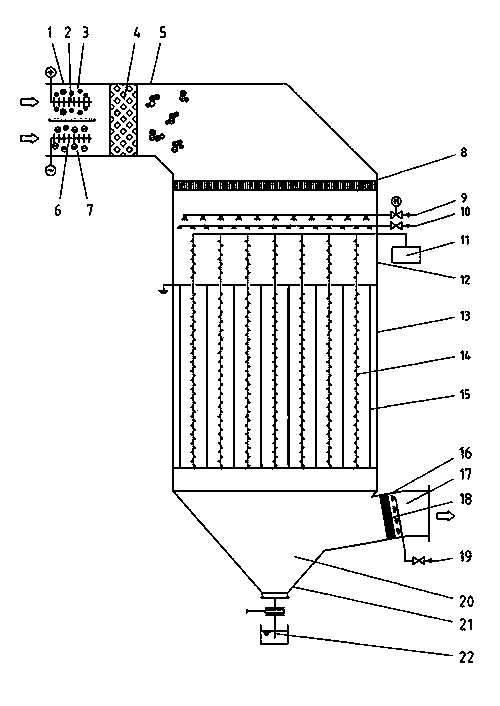

[0021] This embodiment provides a figure 1 A wet electrostatic precipitator for removing fine particles in the flue gas after wet desulfurization is shown, including a casing, which is arranged at the flue gas inlet end on the upper part of the casing, and is arranged at the dust charging area 1 on the upper part of the flue gas inlet end 1. The dust collection area 13 located in the middle of the casing, the flushing device located above the dust collection area 13, the flue gas outlet area 17 and the ash discharge area 20 located below the dust collection area 13, and the dust charging area The coagulation and agglomeration area 5 behind area 1, the coagulation and agglomeration area 5 is provided with a flue gas turbulence device 4, and a secondary pre-charging area 12 is provided between the flushing device and the dust collection area 13, and the secondary pre-charging area The upper part of 12 is equipped with an air flow uniform distribution device 8, the flushing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com