A chemical admixture to improve the performance of concrete expansion agent under limited conditions

A restrictive condition and concrete technology, applied in the field of chemical admixtures, can solve problems such as complex production process, non-compliance with the national low-carbon and environmental protection industrial policy, difficulty in quality control and increased production energy consumption

Active Publication Date: 2015-12-30

XIDI (SUZHOU) SURVEY & DESIGN CONSULTING CO LTD +1

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0016] These methods have a certain effect on improving the expansion performance of the expansion agent, but often have limited effects, and make the production process too complicated, with redundant links, greatly increasing the difficulty of quality control and production energy consumption, which does not meet the national low-carbon environmental protection policy. Industrial policy, and in terms of economic benefits, its actual effect is often not as direct and simple as increasing the amount of expansion agent

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0034] CaO clinker 10g, sodium tripolyphosphate 0.05g, deionized water 20ml.

Embodiment 2

[0036] CaO clinker 10g, sodium hexametaphosphate 0.20g, deionized water 20ml.

Embodiment 3

[0040] Standard cement 405g, standard sand 1350g, CaO clinker 9g, gypsum 15g, fly ash 21g, sodium tripolyphosphate 0.05g, mixing water 225g.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

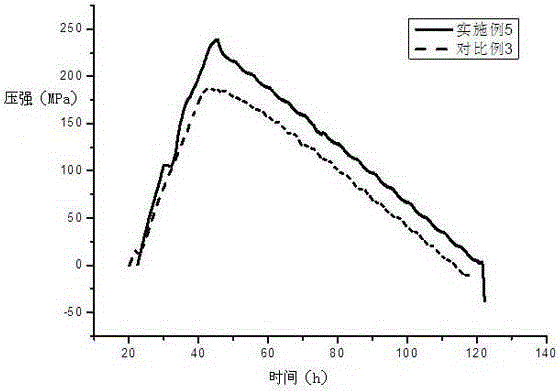

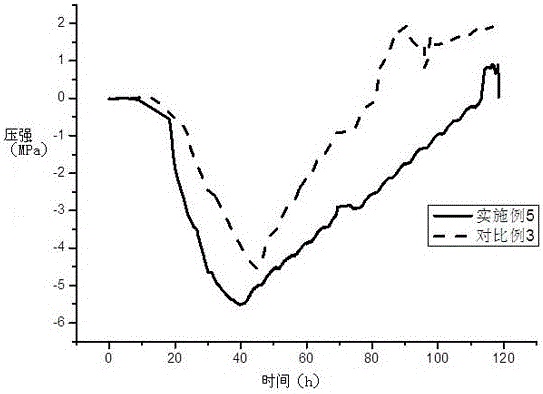

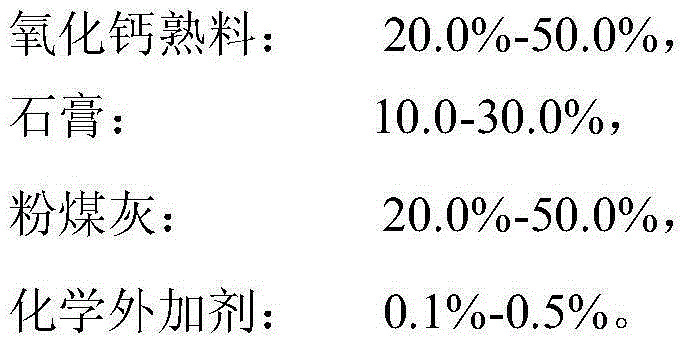

The invention provides a chemical admixture capable of improving the effectiveness of a concrete expanding agent under a restrictive condition. The chemical admixture accounts for 0.1-0.5% of the total weight of the concrete expanding agent, and the concrete expanding agent comprises the rest components as follows: 20.0-50.0% of calcium oxide clinker, 10.0-30.0% of gypsum and 20.0-50.0% of fly ash. The chemical admixture has the benefits as follows: when the adding amount of the chemical admixture is the same, the effect of the concrete expanding agent in a cement-based material under a free condition is remarkably improved and the free expanding rate is increased; the effect of the concrete expanding agent in the cement-based material under the restrictive condition is remarkably improved and the effective expanding rate is increased, so that the chemical admixture is more suitable for a sidewall, a roof and other solid structures with relatively strong constraints; mechanical properties and durability of the cement-based material are slightly affected, so that actual control and use are facilitated.

Description

technical field [0001] The invention relates to a chemical admixture for improving the performance of a concrete expansion agent under restricted conditions, which can increase the limited expansion rate of the expansion agent under strong constraints in engineering practice, and is especially suitable for side walls, roofs, etc. that are poured with shrinkage-compensating concrete. Strongly restrained solid structure, which is beneficial to compensate shrinkage and crack resistance. Background technique [0002] Due to the low water-binder ratio, the extensive use of mineral admixtures, and the compact structure of modern concrete, it is easy to shrink and crack in large quantities during the construction period, which seriously affects the performance of the structure. Judging from the existing research results and engineering practice, shrinkage-compensated concrete is one of the better means to solve the problem of shrinkage cracking of large-volume, large-area and super...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B22/16C04B22/14C04B22/06

Inventor 韩锡云袁志刚徐文王育江许洵嘉张瑶

Owner XIDI (SUZHOU) SURVEY & DESIGN CONSULTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com