Cover type ball screw with double nut preload structure

A ball screw, end cap technology, applied in belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problems of large distance, non-circulating balls, and low strength of thin shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

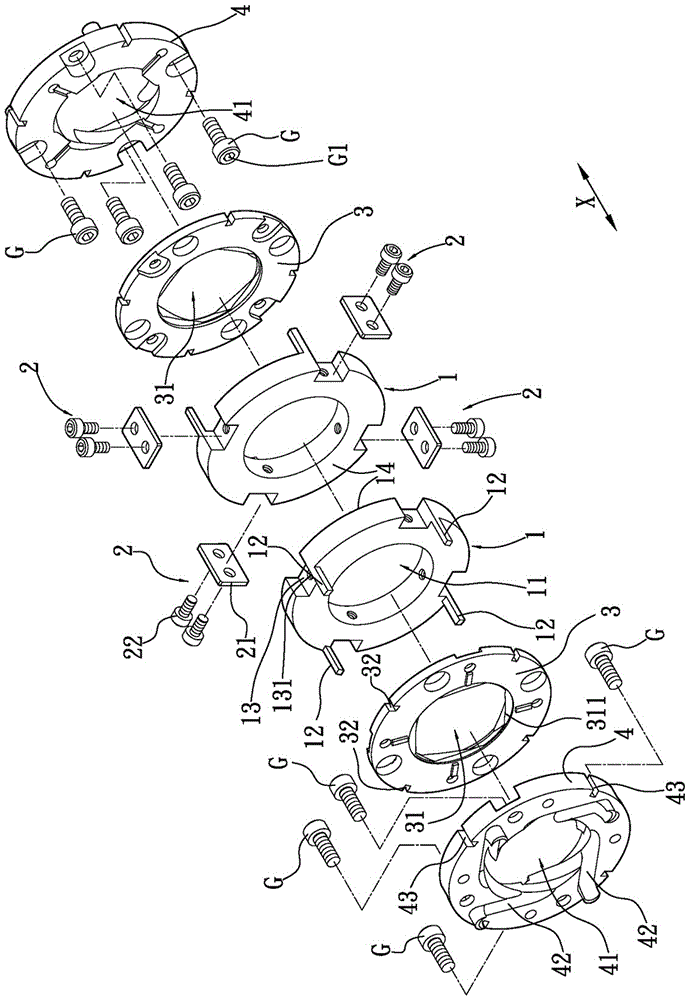

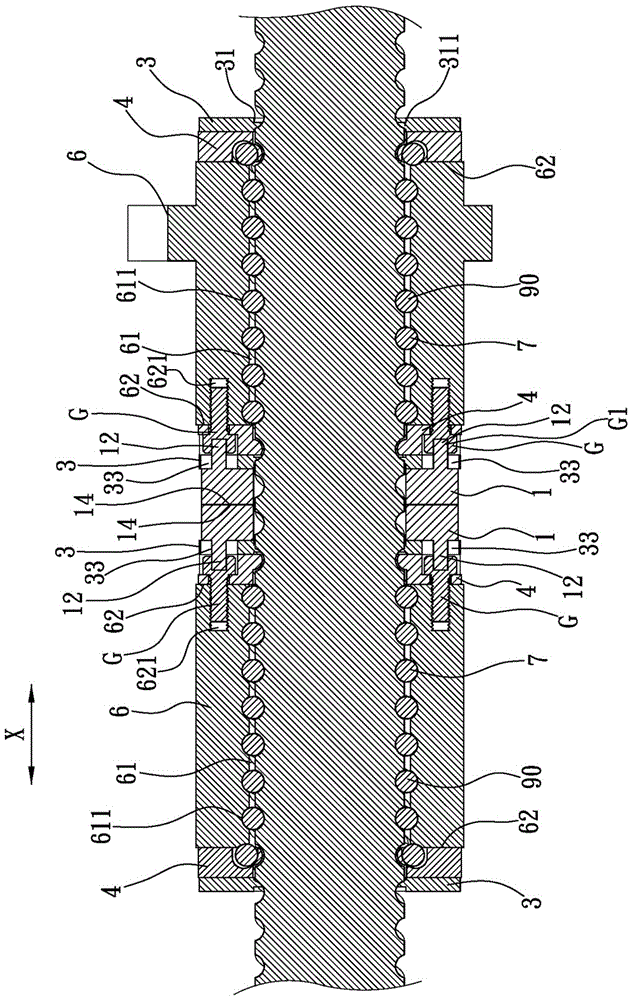

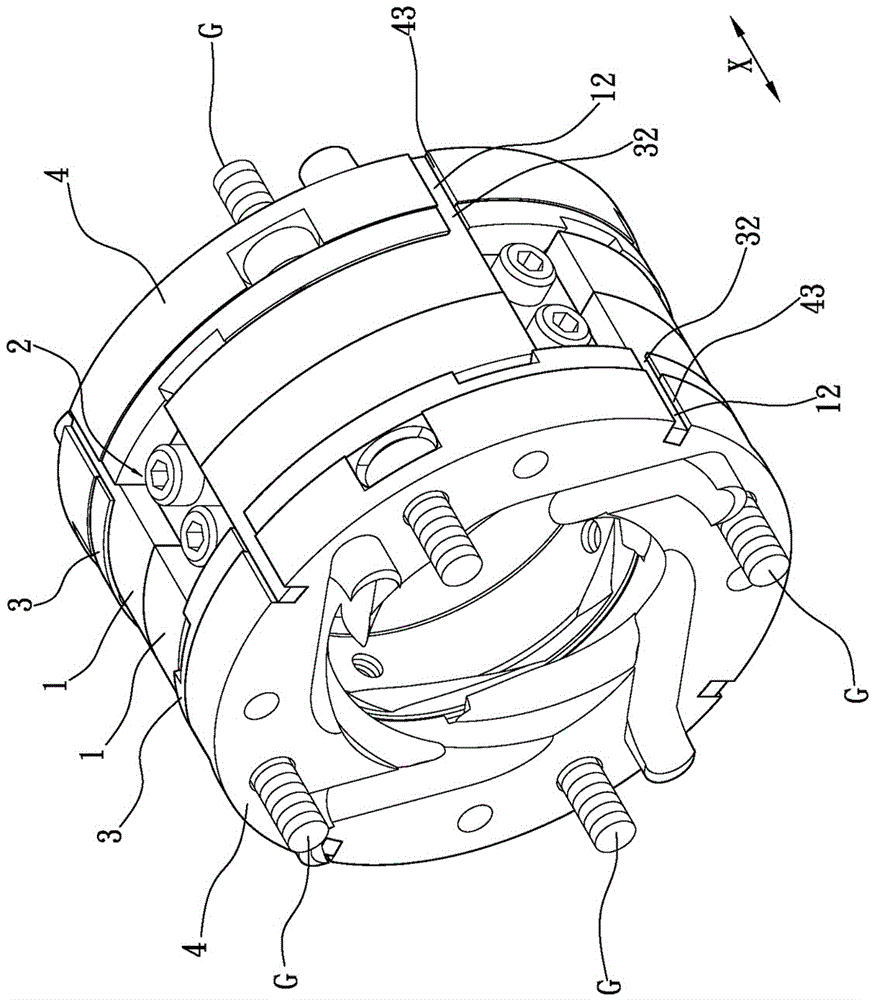

[0050] First, see Figure 1 to Figure 5 As shown, it is the accompanying drawing of the first preferred embodiment of the present invention. The present invention is an end-cap type ball screw with double-nut preloading structure, including:

[0051] Multiple rolling elements 7;

[0052] A major axis 5, which is a strip-shaped structure extending in one direction, defining the extending direction as the axial direction X, and the outer edge surface of the major axis 5 is provided with a spiral rolling groove 51;

[0053] The two nuts 6 each have a perforation 61 for the long axis 5 to pass through. The inner edge of the perforation 61 is provided with a rolling groove 611 opposite to the rolling groove 51. The rolling groove 51 and the rolling groove 611 form a load path 90, and the two ends of the axial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com