A kind of anti-force drag cable hanging basket preloading device and its implementation method

An implementation method and a reaction-force technology, which are applied in the field of the reaction-type traction cable hanging basket pre-compression device, can solve the problems of short time consumption, many times of horizontal and vertical transportation, and low difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

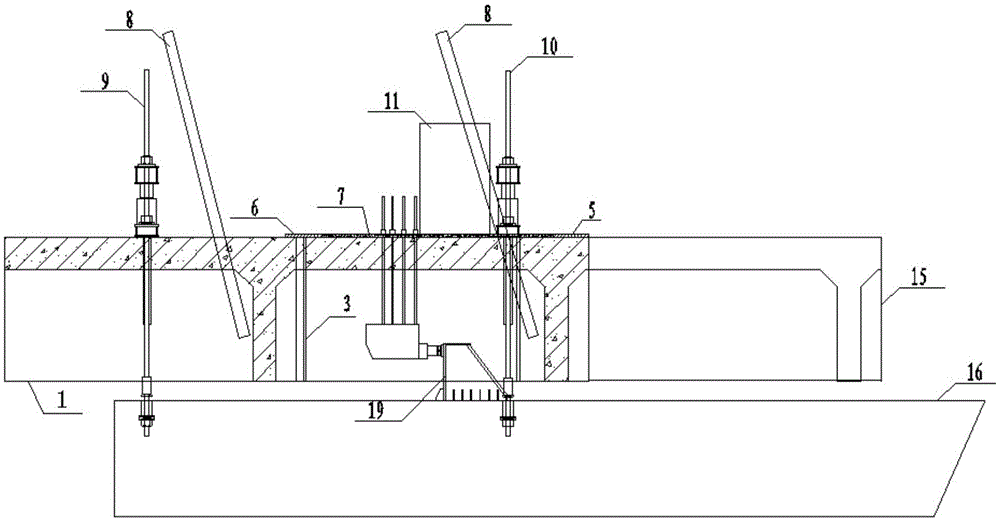

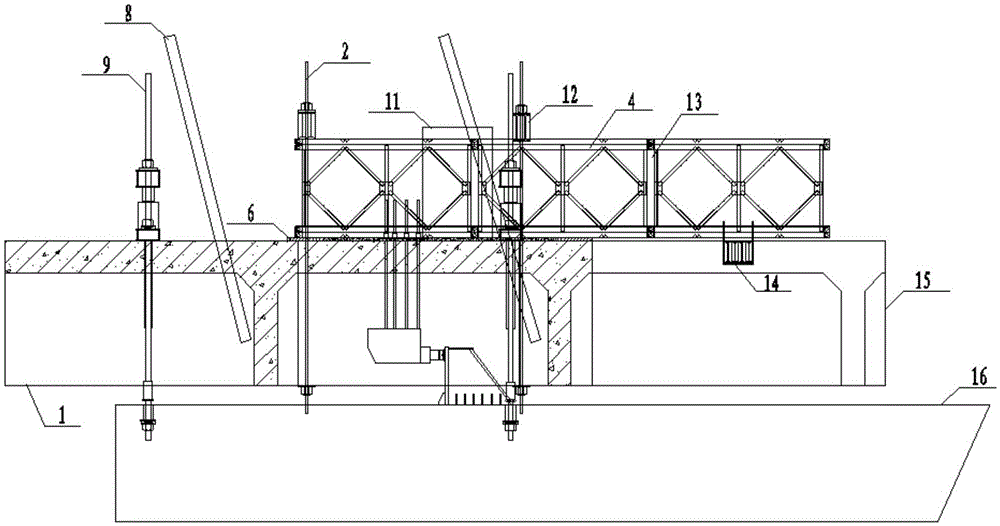

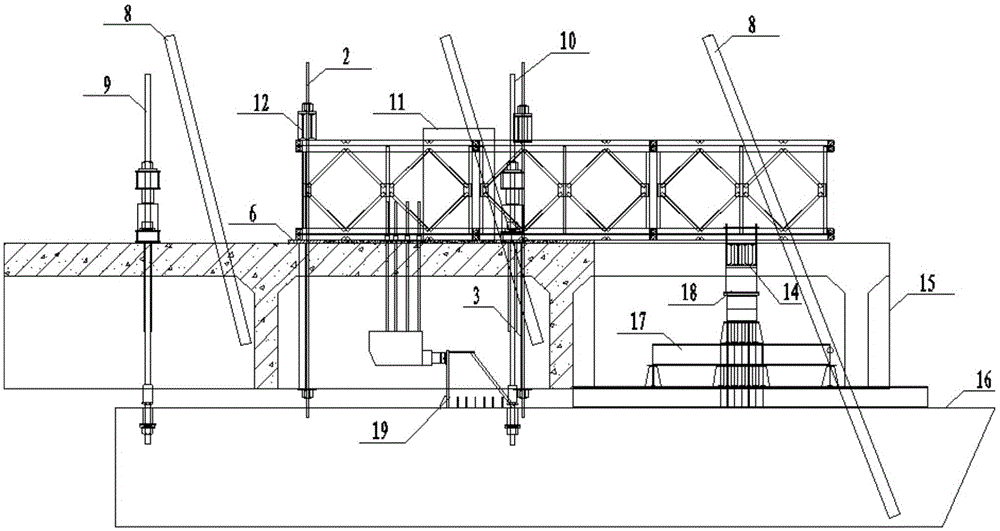

[0027] Such as Figure 1-3 As shown in the figure, a preloading device of a reaction type stay cable hanging basket includes a Bailey reaction beam 4 anchored on the poured beam section 1 with an anchor 2, and a jack base 17 placed on a hanging basket carrying platform 16 And the hydraulic jack 18 is characterized in that: it also includes a reserved hole 3, a front backing plate 5, a rear backing plate 6, a leveling layer 7, a connecting beam 12, a backing beam 14 and a thrust system 19; the reserved hole 3 Reserve before pouring the poured beam section 1; the Bailey reaction beam 4 is anchored at the reserved hole 3 of the poured beam section 1 through the anchor 2 and the connecting beam 12, and a cushion is set at the position of the front end jack 18 Beam 14; the jack base 17 and the jack 18 are placed at the beam section 15 to be poured on the hanging basket carrying platform 16; the thrust system 19 is an integral part of the dragline hanging basket, and the top is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com