Combined cabinet

A combined type and cabinet technology, which is applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, etc., can solve problems such as insufficient bearing capacity, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

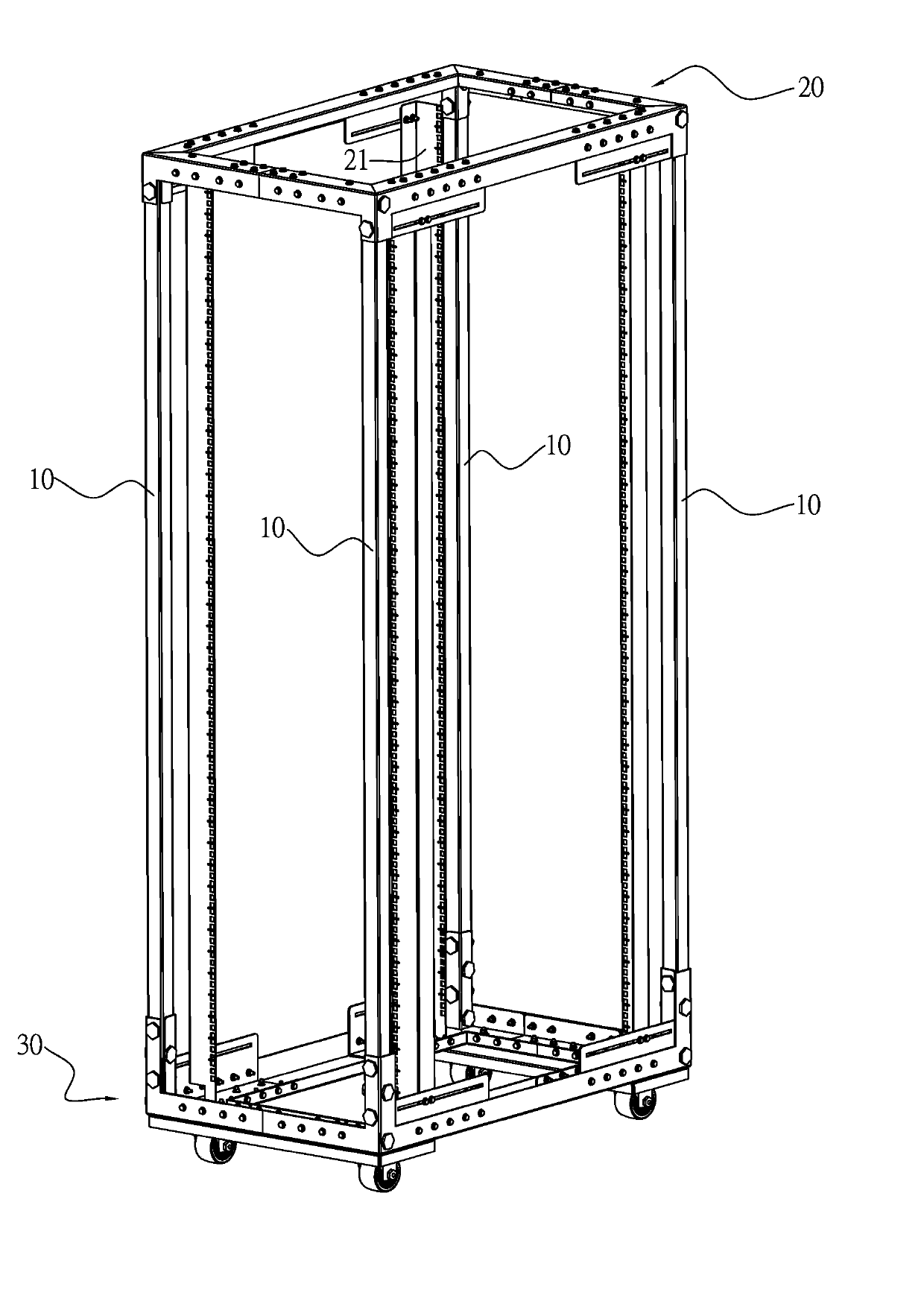

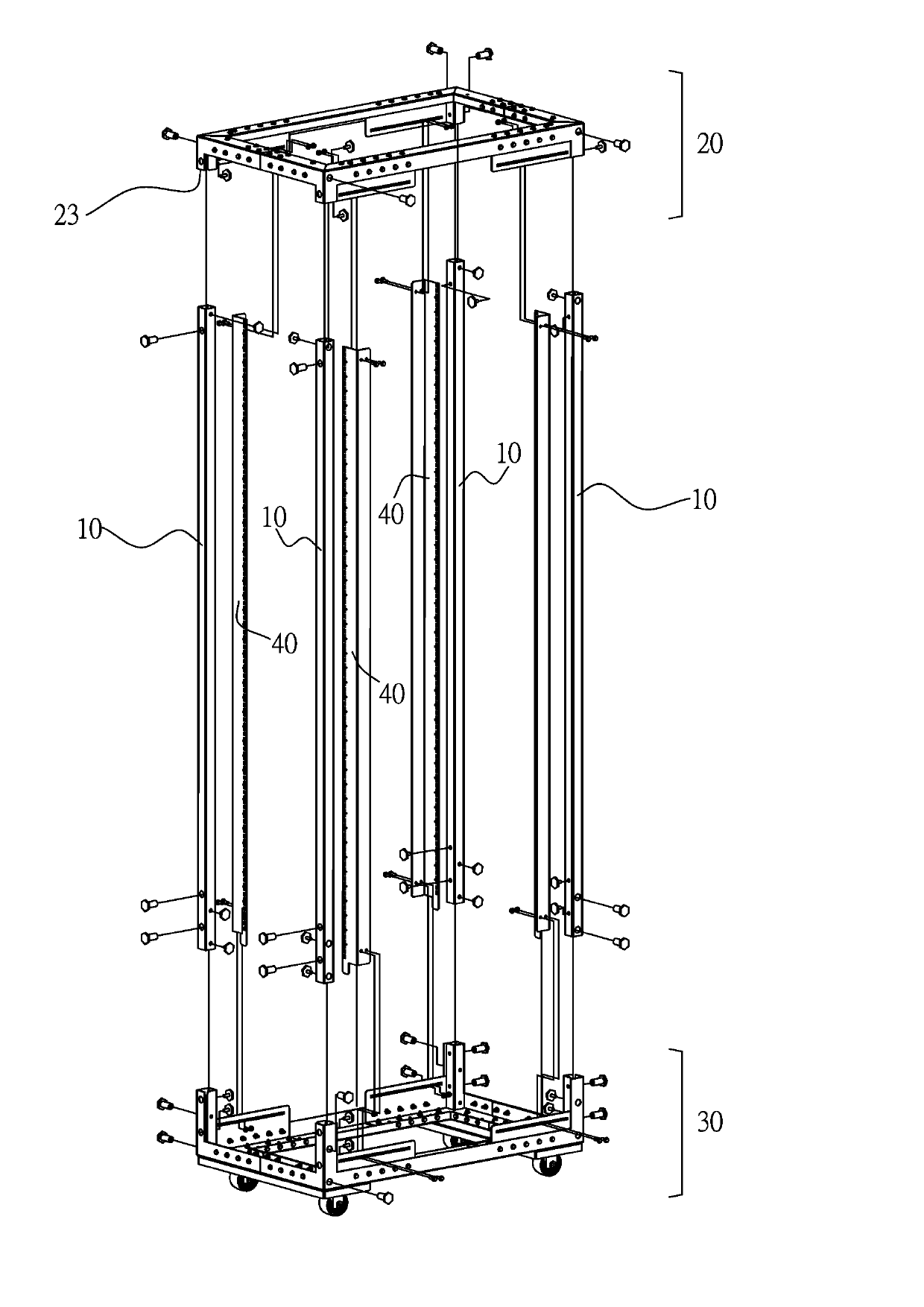

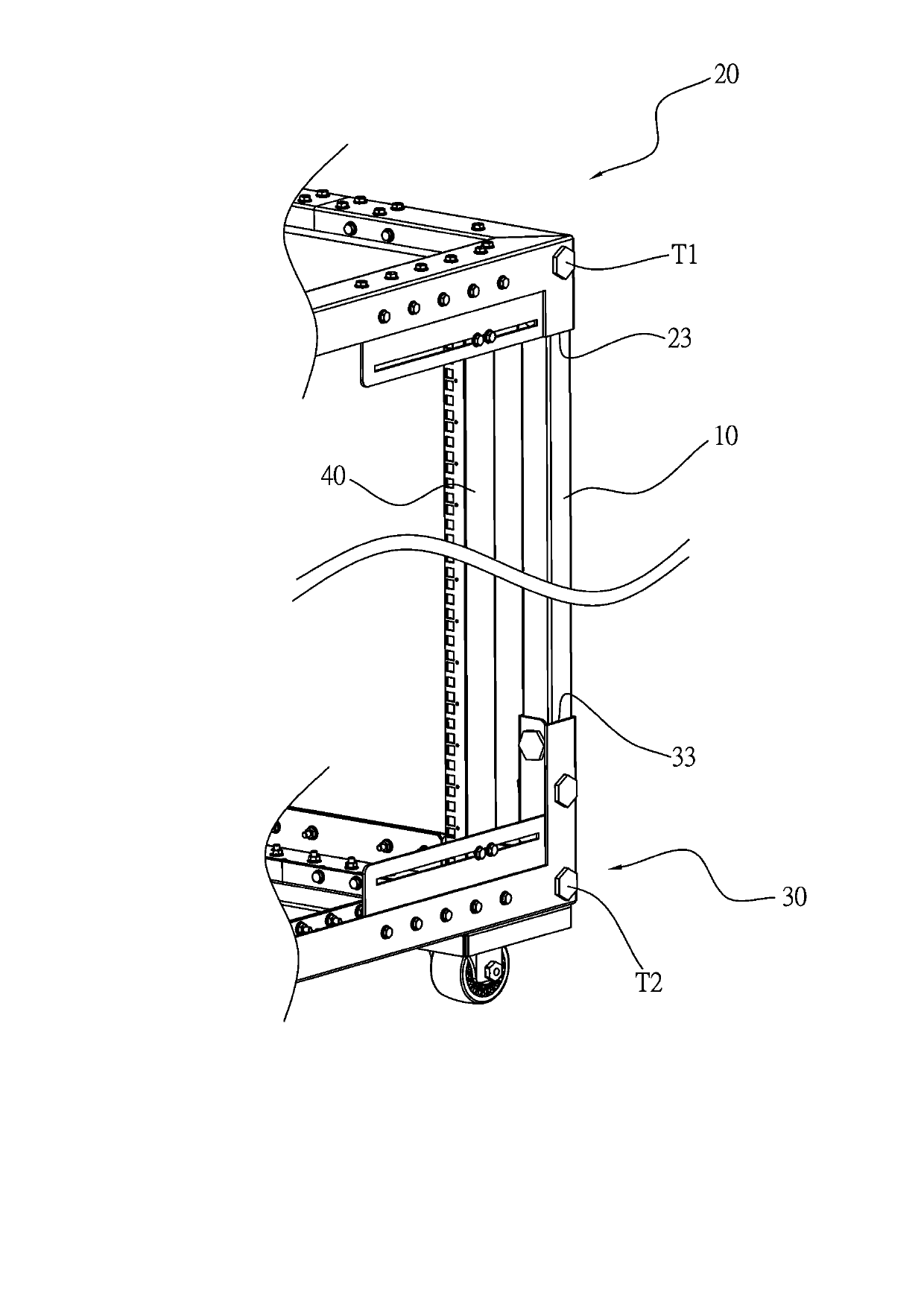

[0060] see Figure 1 to Figure 2 The combined cabinet shown in this embodiment includes four columns 10 , an upper frame module 20 , and a lower frame module 30 . In this way, the storage space can be reduced, and the number of pieces transported in one trip can be increased, and the load capacity has also been greatly increased. The detailed structure is as follows:

[0061] Such as Figure 2 to Figure 5 As shown, the upper frame module 20 includes an upper frame 21 , an upper connecting seat set 22 and at least four upper fixing grooves 23 . The upper connecting seat set 22 includes a plurality of upper connecting seats 221 , and these upper connecting seats 221 are combined with the inner side of the upper frame 21 . The upper fixing groove 23 is formed by combining the upper frame 21 and the upper connecting seat 221, and is used for inserting one end of any cylinder 10, and at least one upper locking component T1 is used to fix the cylinder 10 and the upper fixing groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com