Low-disturbance wave efficient-vibration vertical piano

An upright piano, low-disturbance technology, applied in the field of musical instruments, can solve the problems of small attenuation, shortened string vibration time, large shock wave, etc., and achieve the effects of increasing vibration space, improving vibration efficiency, and eliminating disturbance waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

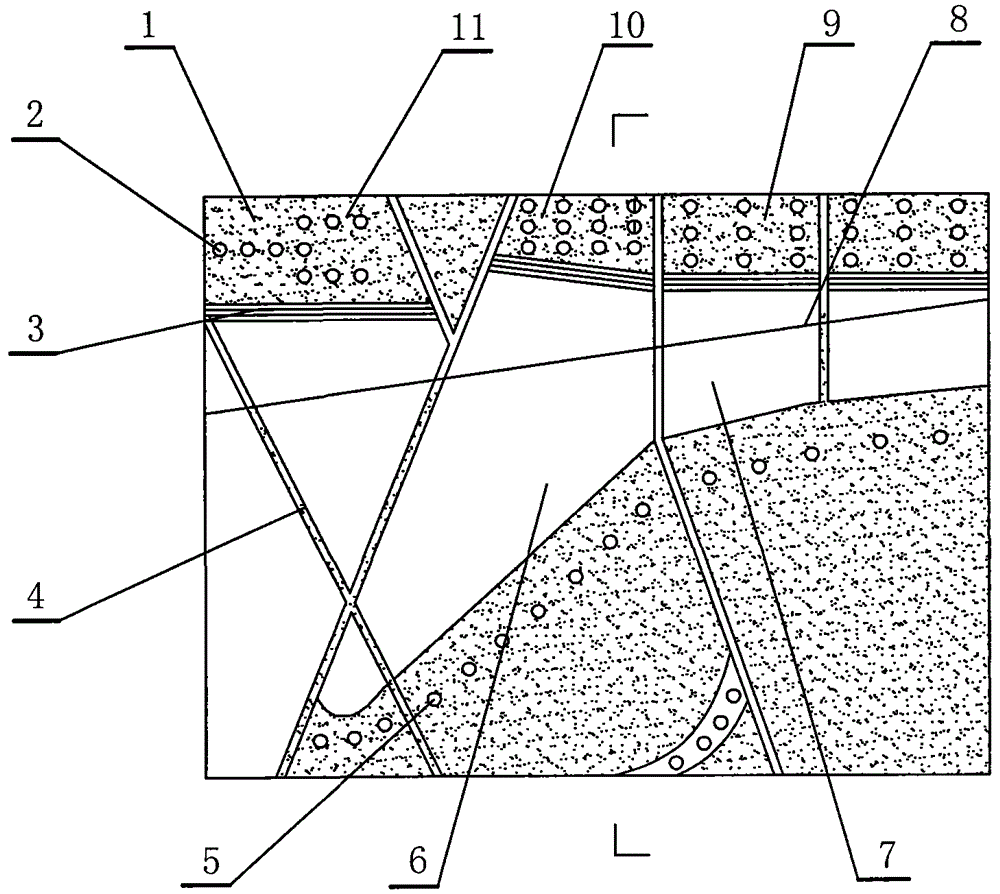

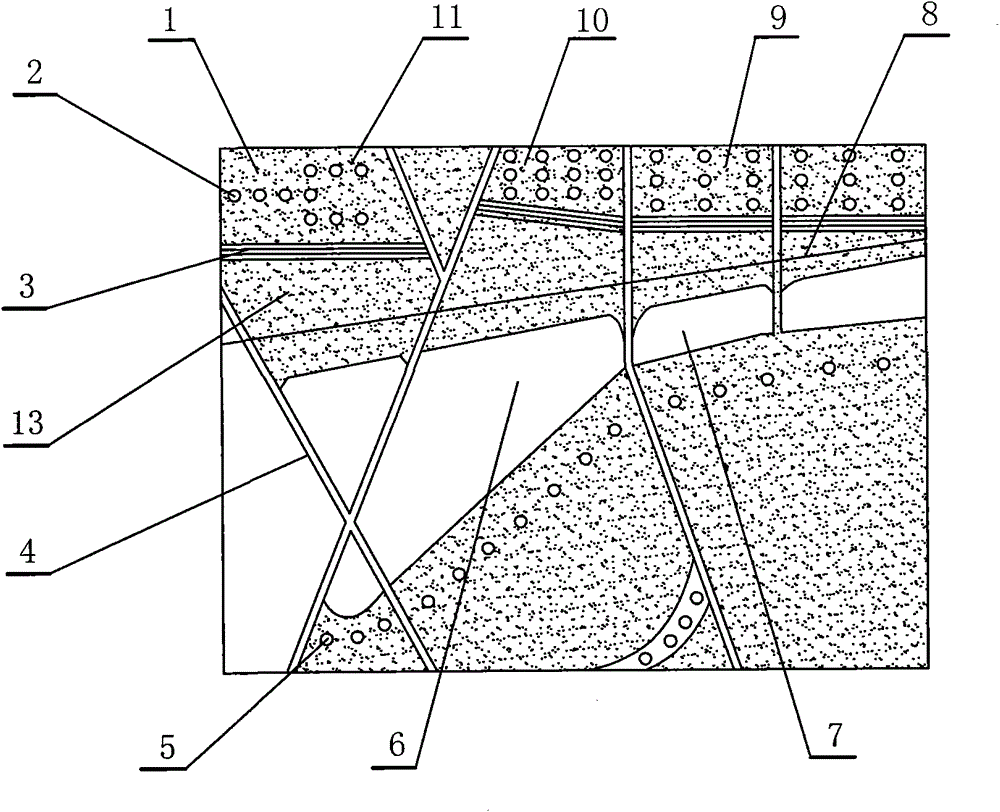

[0018] The general idea of the present invention is to raise the upper edge of the sound opening of the cast iron plate of the upright piano above the hammer line. Introduce four kinds of embodiments below in conjunction with accompanying drawing:

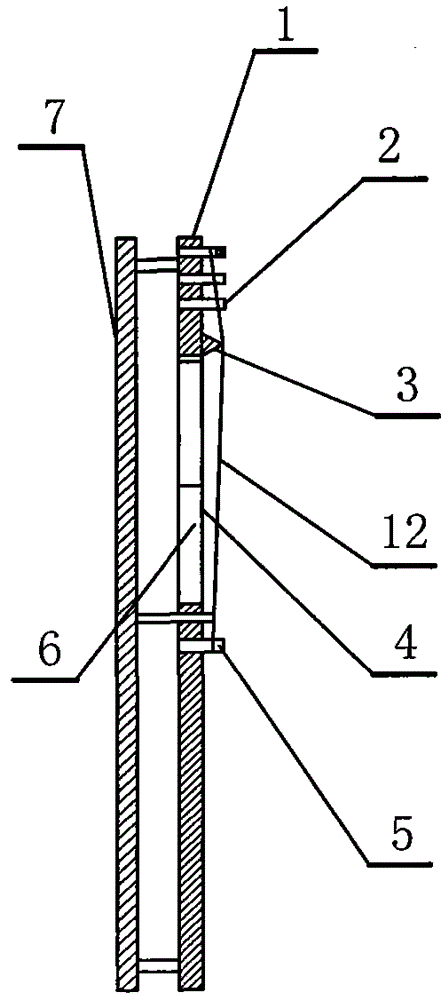

[0019] The first embodiment: figure 1 figure 2 A cast iron plate for an upright piano with low disturbance wave and high-efficiency vibration is introduced. A plurality of pegs 2 are set on the upper end of the cast iron plate 1, and long ribbed string nuts 3 are arranged horizontally below the pegs 2. The cast iron plate 1 The middle and lower parts are provided with a plurality of string-hanging stakes 5 . The upper ends of the plurality of strings 12 of the piano are respectively connected to the pegs 2 , and the lower ends are respectively connected to the plurality of hanging stakes 5 , and a certain distance is kept from the cast iron plate 1 under the support of the saddle 3 . A layer of wooden soundboard 7 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com