PCB washing pool

A technology for printed circuit boards and circuit boards, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve tin whisker control and poor soldering, difficult to reduce production costs, low washing efficiency, etc. problems, to achieve the effect of increasing cleaning efficiency, enhancing vibration and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

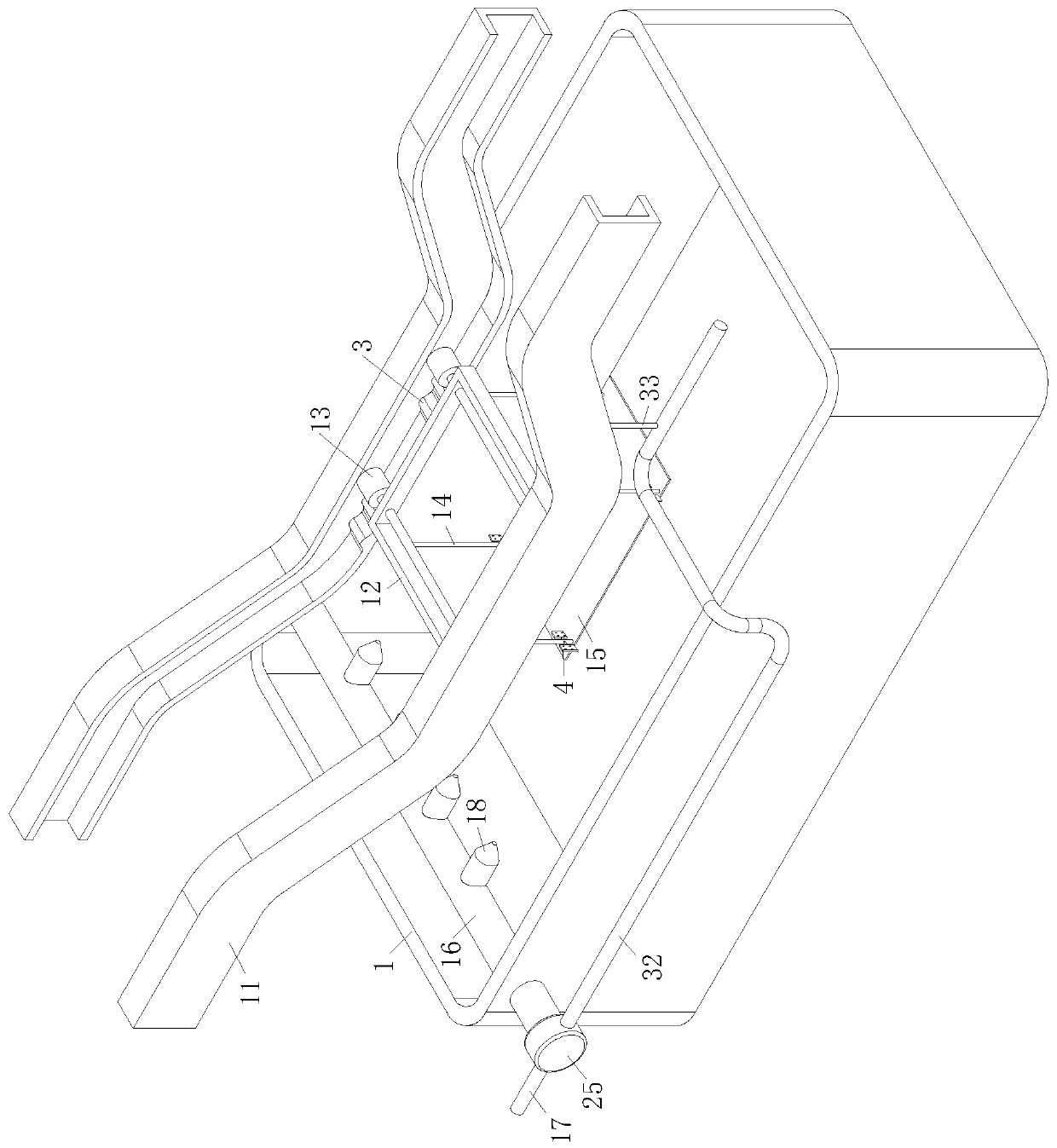

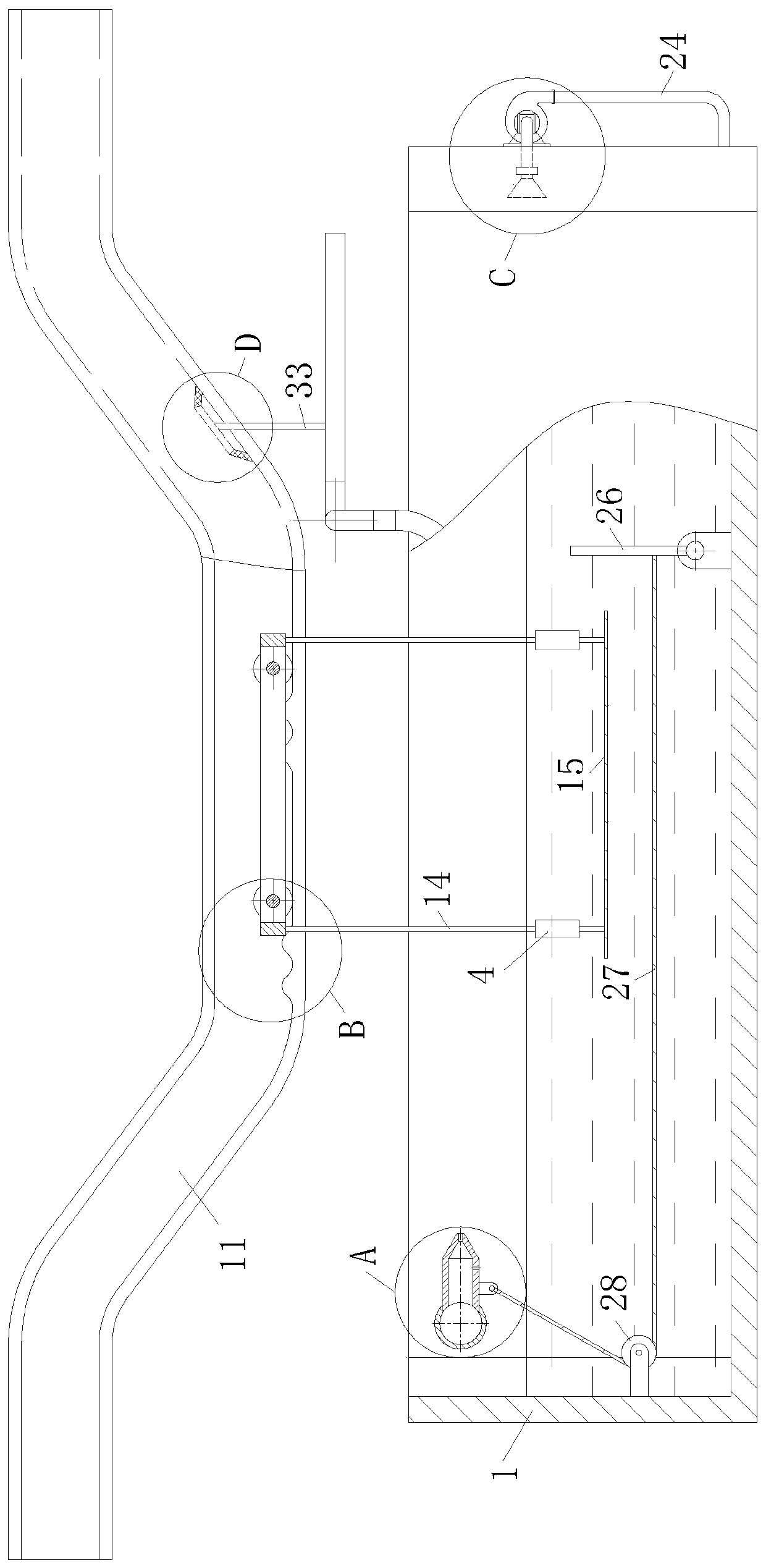

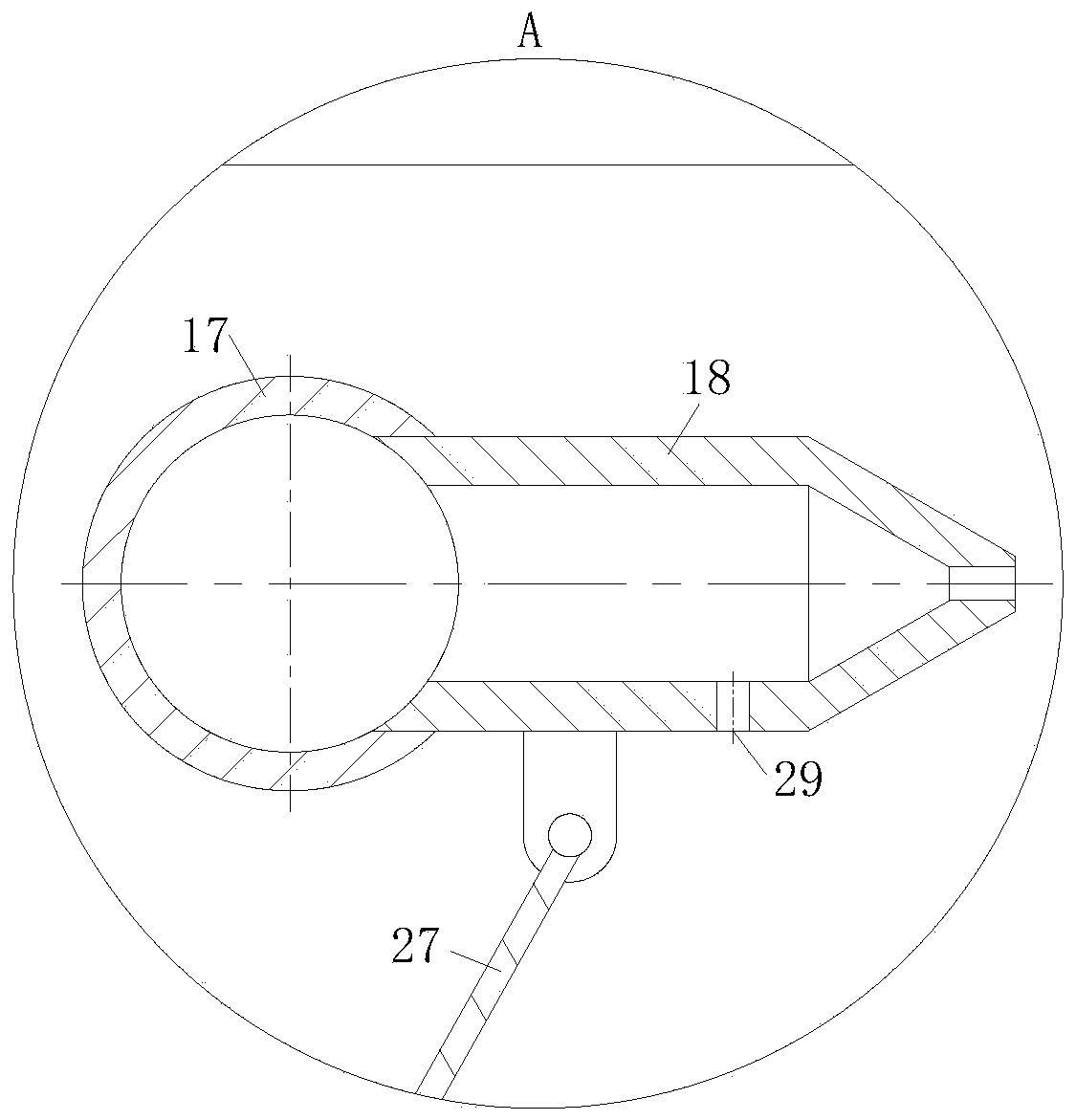

[0028] As an embodiment of the present invention, a main water pipe 16 is provided on one side of the pool 1, the main water pipe 16 runs through the side wall of the pool 1 and extends to the outside of the pool 1, and the end of the main water pipe 16 located outside the pool 1 communicates with the low-pressure water pipe 17 One end of the main water pipe 16 located in the pool 1 is connected with a group of nozzles 18, and the nozzles 18 are arranged horizontally and towards the middle of the pool 1; pure water is sprayed through the nozzles 18 to impact the rope 14, so that the circuit board 15 swings, further increasing The cleaning efficiency of the circuit board 15; after the circuit board 15 enters the pool 1 by the drive of the walking trolley 12, the circuit board 15 is cleaned by detergent. Nozzle 18 sprays out, and pure water impacts rope 14, and rope 14 drives circuit board 15 to swing back and forth in pool 1, and the pure water ejected simultaneously drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com