Mill pinlon tool

A technology of tooling and gearing, which is applied in the direction of gear tooth manufacturing devices, gear teeth, manufacturing tools, etc., can solve the problems of undercutting, damage to gears, and inability to meet gear displacement during hobbing processing, so as to improve stability and positioning Stable and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

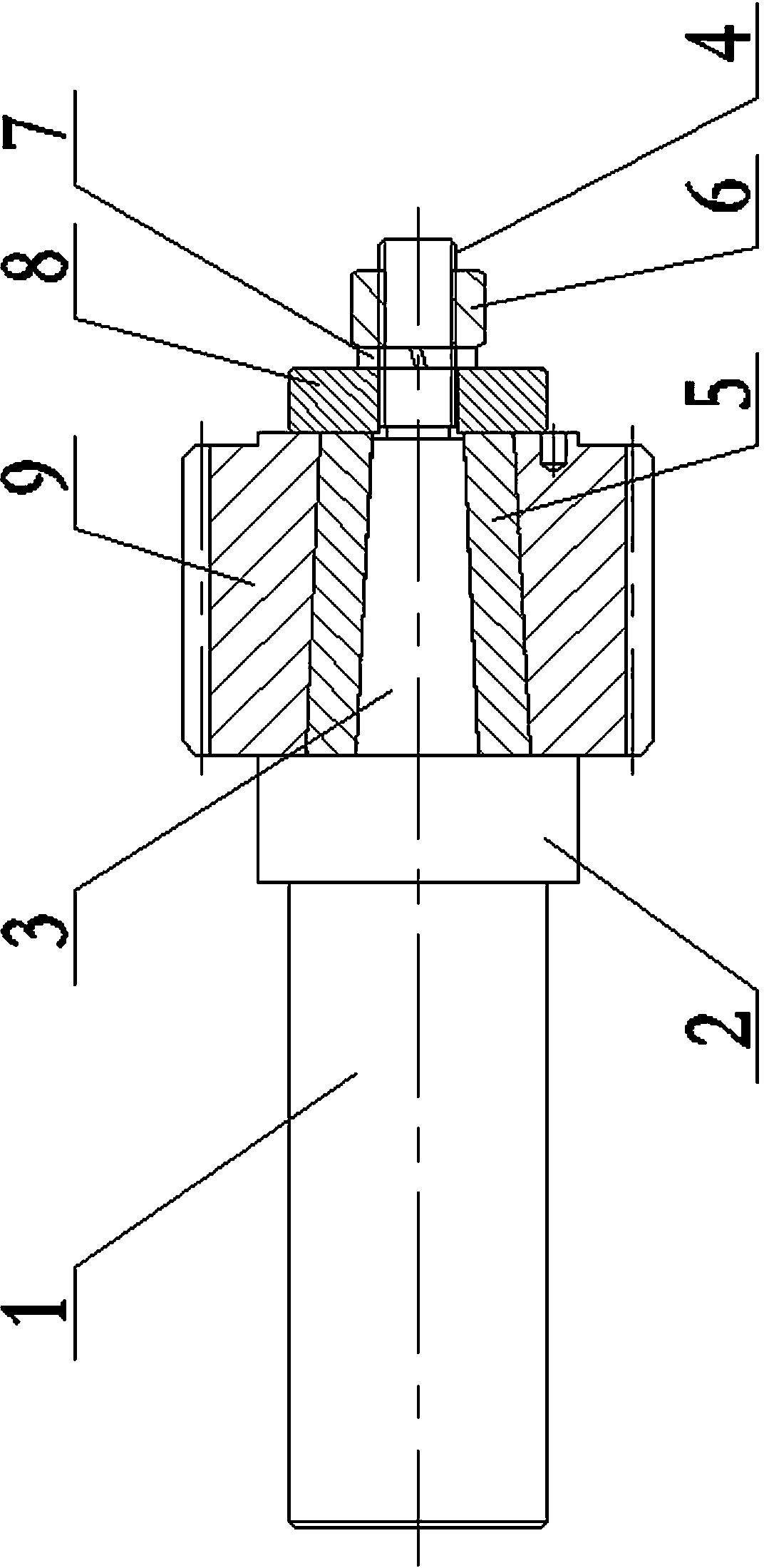

[0012] figure 1 As shown in the figure, a tooling of a mandrel wheel includes a mandrel 1, a shoulder 2, a tapered table 3, a bolt part 4, a tapered sleeve 5, a nut 6, a spring washer 7 and a gasket 8, and one end of the mandrel 1 is sequentially arranged from the inside to the outside. A shoulder 2, a conical platform 3 and a bolt part 4 are provided at the same time. The conical sleeve 5 is set on the conical platform 3. One end of the conical sleeve 5 is pressed against the shoulder 2, and the other end is passed through the spring washer 7 by the nut 6 in turn. , The gasket 8 is screwed to the bolt part 4 and compressed;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com