Piezoelectric ink jet head and printing device with piezoelectric ink jet head

A technology of ink head and piezoelectric ceramics, which is applied in the field of piezoelectric inkjet head and printing equipment, can solve the problems of small deformation of inkjet head and unfavorable large particle size ink ejection, etc., achieve large deformation pressure, increase ejection speed, The effect of large amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

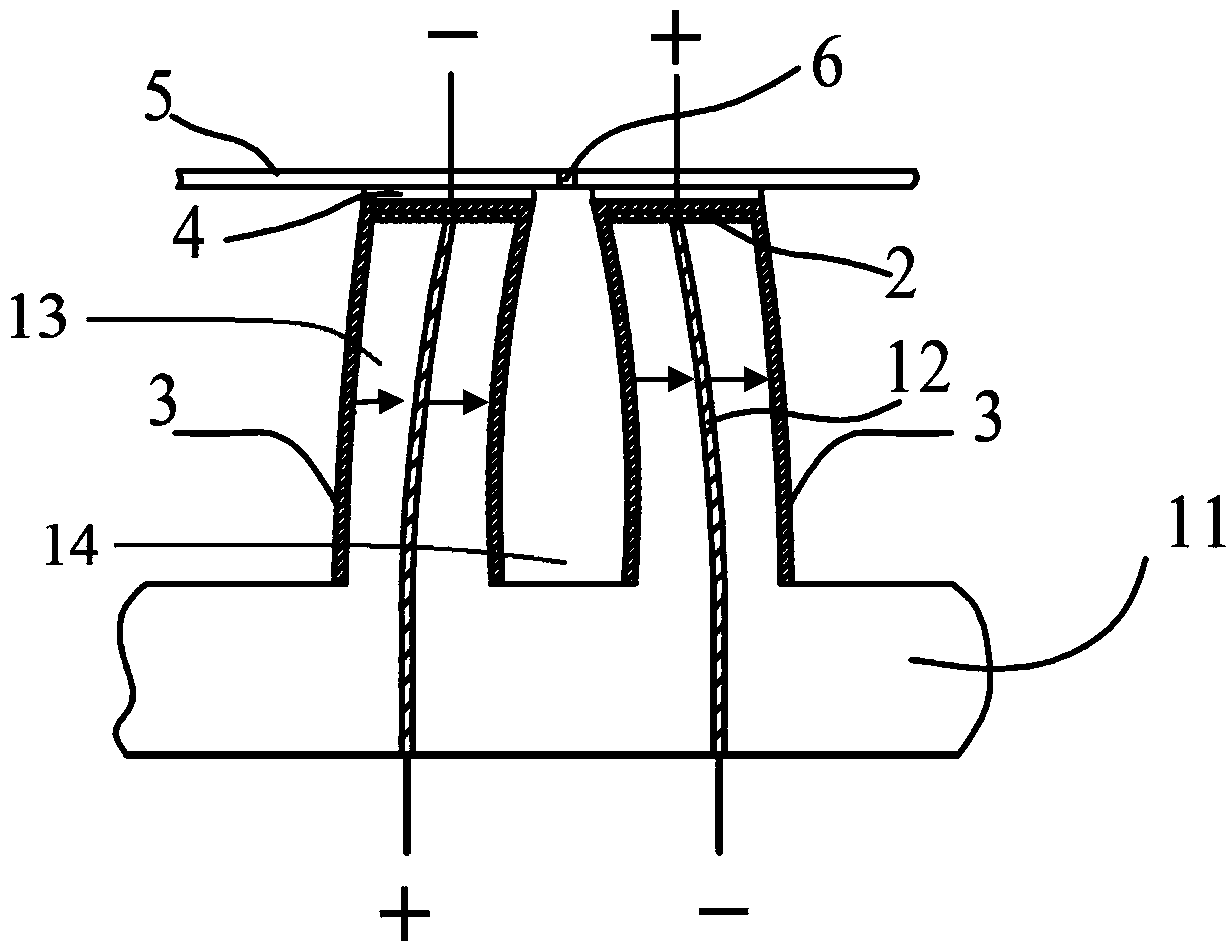

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

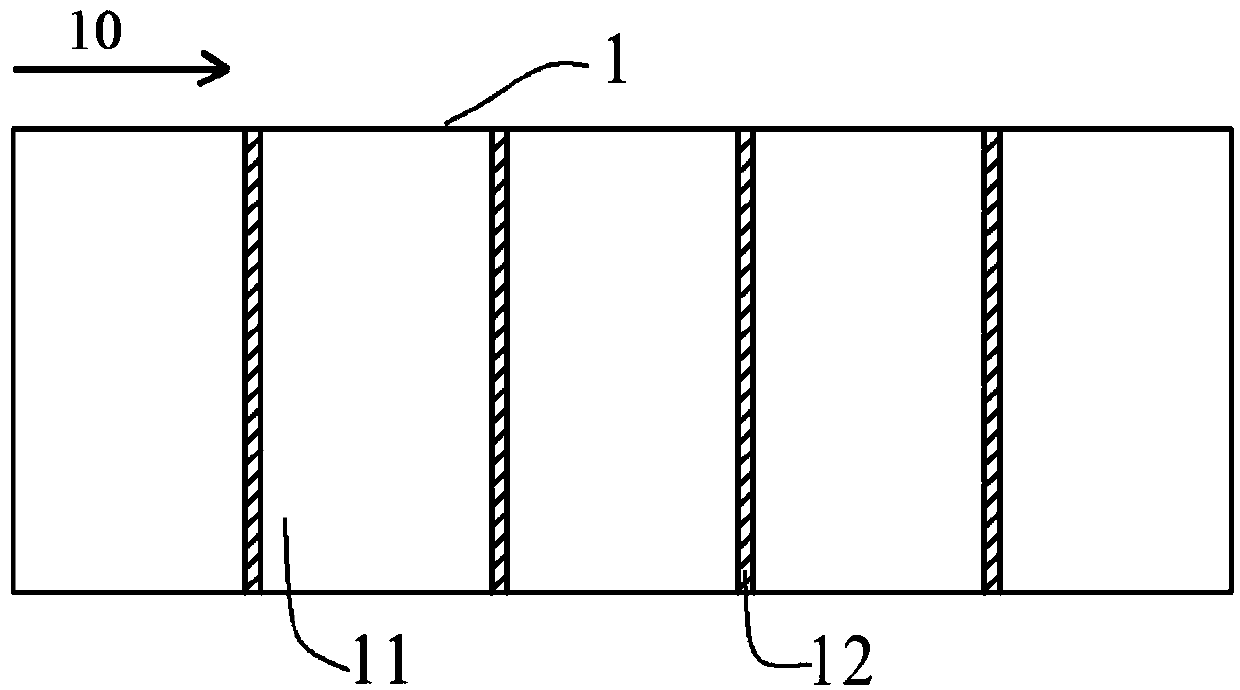

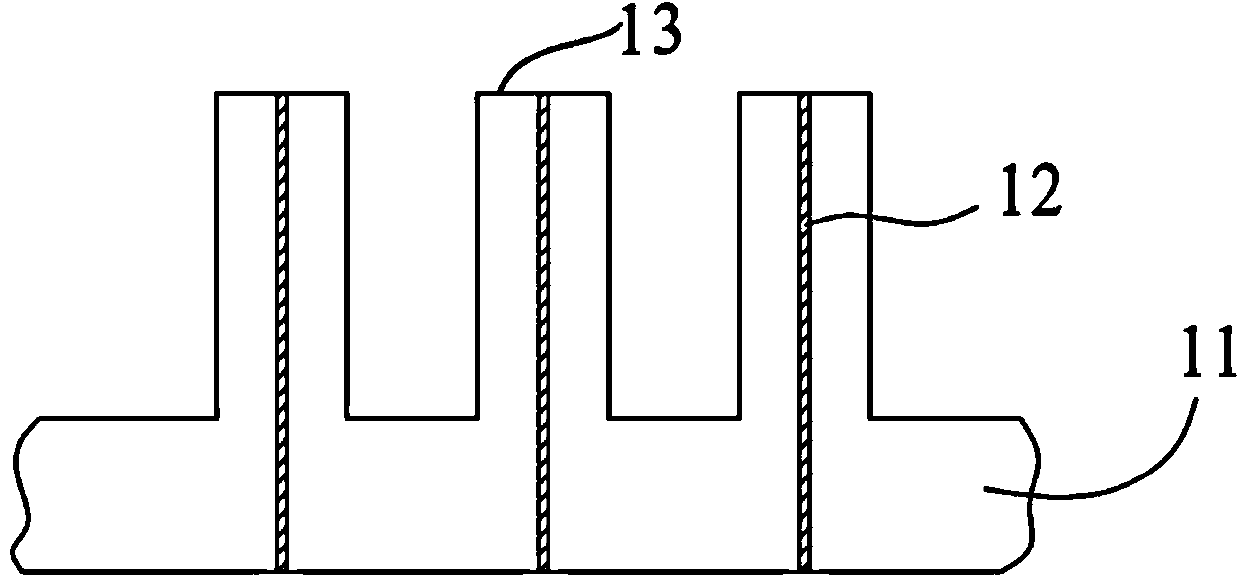

[0032] In one aspect, the present invention provides a piezoelectric inkjet head, such as Figure 1-12 As shown, including piezoelectric ceramics 1, 1' and nozzle plates 5, 5', piezoelectric ceramics 1, 1' are provided with several strip-shaped channel walls 13, 13', between two adjacent channel walls 13, 13' Grooves 14, 14' (ie, ink channels) are formed between them, and metal internal electrodes 12, 12' are embedded in the channel walls 13, 13', thereby forming a piezoelectric bimorph structure. The outer surface of the channel walls 13, 13' External electrodes 3, 3' are provided, and the polarization direction of the channel walls 13, 13' is perpendicular to the channel walls 13, 13';

[0033] The nozzle plates 5, 5' are covered on the far-end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com