Piezoelectric nozzle and processing method thereof, and spraying equipment including the nozzle

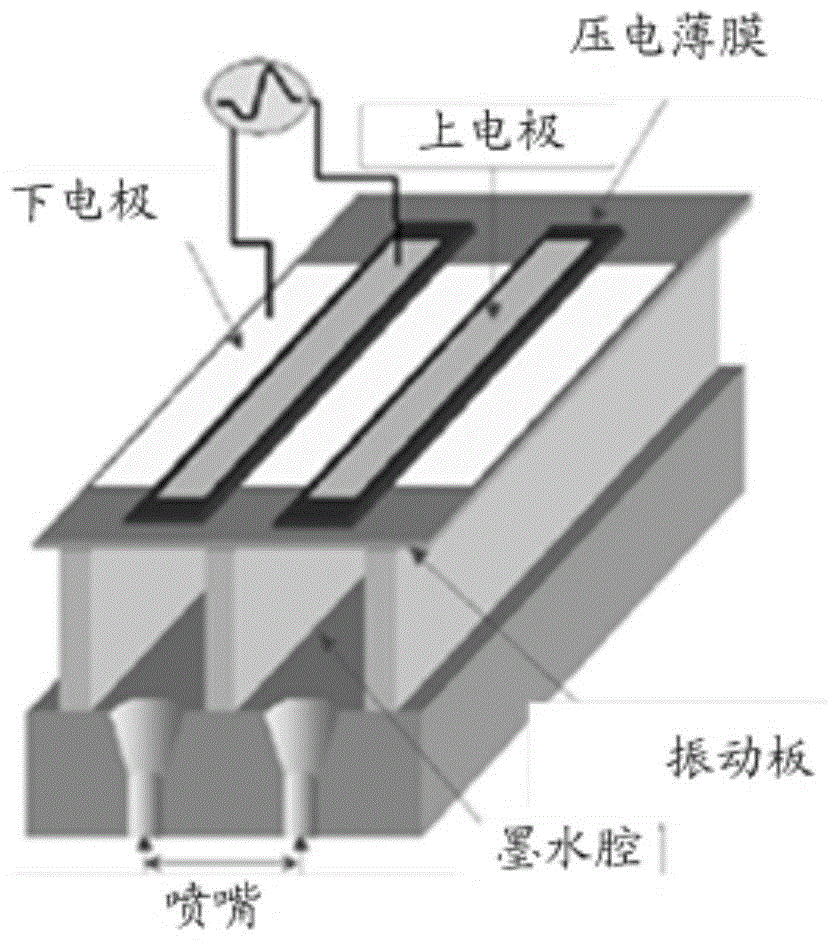

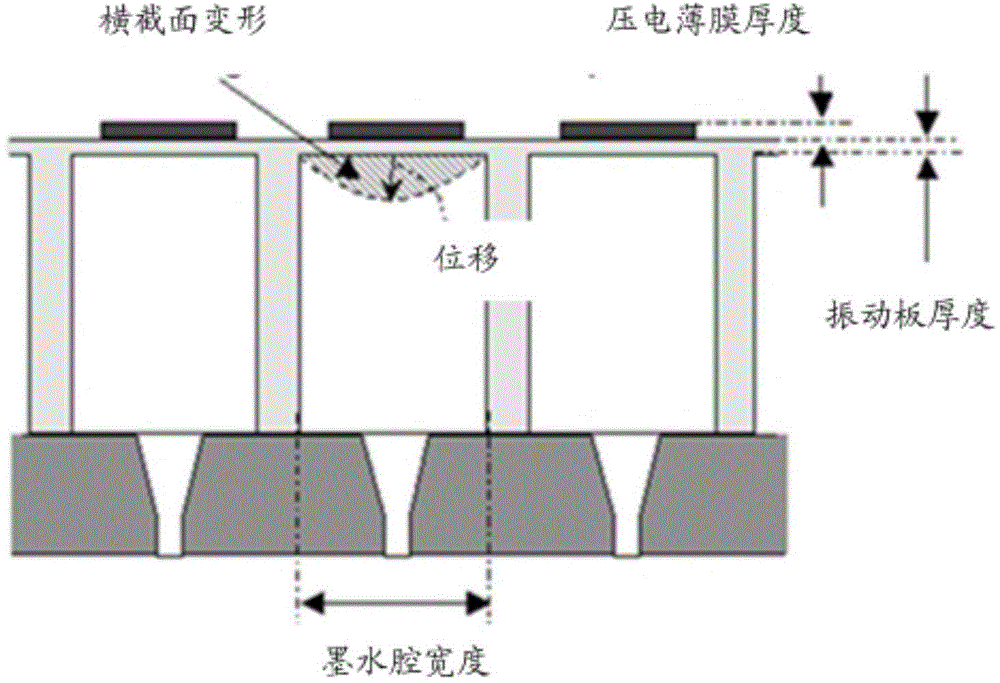

A piezoelectric ceramic and nozzle technology, applied in the field of piezoelectric ceramics, can solve the problems of low output force, easy wear of the parts of the nozzle, and small deformation of the ink chamber, so as to increase the initial speed, improve the work efficiency, and have a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

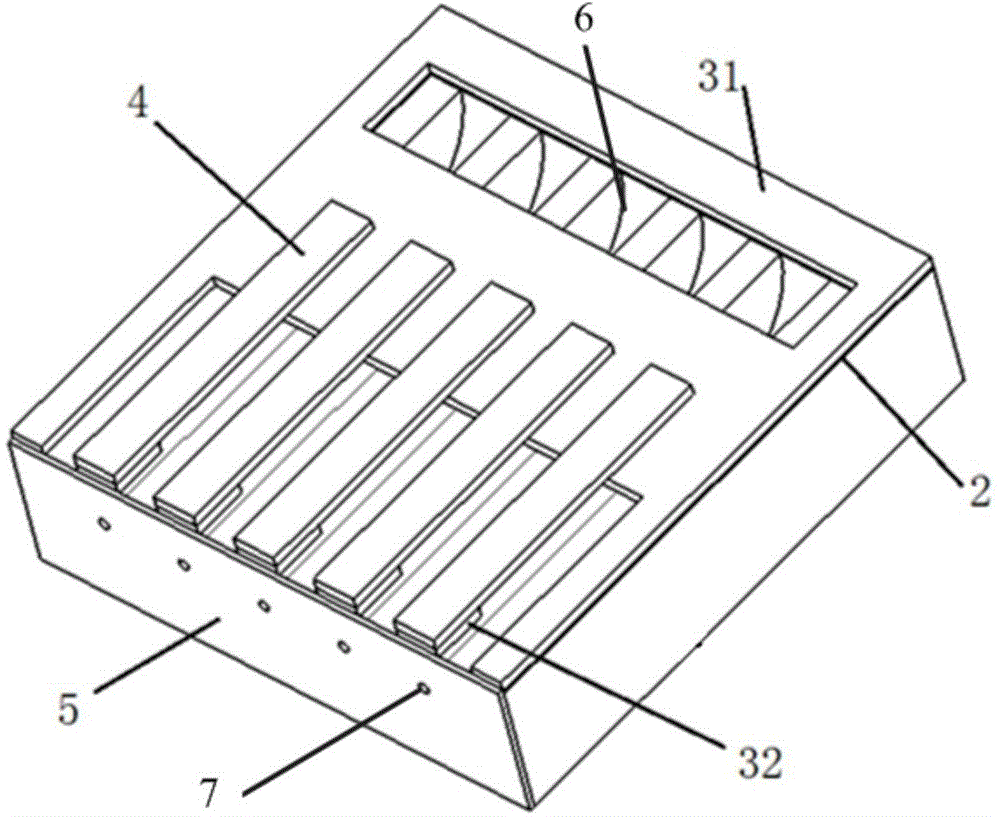

[0050] The ink tank 1 is a tank body with one end closed and one end open, wherein:

[0051] There is a window at the closed end of the ink tank 1 on the flexible diaphragm 2 and the support 31 to form the ink inlet 6, such as Figure 6 As shown; or, the bottom of the closed end of the ink tank is provided with a through hole to form an ink inlet;

[0052] The nozzle 7 is arranged on the nozzle plate 5, and the nozzle plate 5 is glued to the end surface of one end of the opening of the ink tank 1;

[0053] The nozzle is set on the nozzle plate. When the nozzle fails, only the nozzle plate needs to be replaced instead of the entire piezoelectric nozzle.

Embodiment 2

[0055] The ink tank is a tank body with one end closed and one end open, wherein:

[0056] The end surface of one end of the opening of the ink tank is used as an ink inlet;

[0057] One end of the opening is used as the ink inlet, and no additional ink inlet is required, which is simple and convenient;

[0058] There is a small hole on the end surface or the bottom surface of the closed end of the ink tank as a nozzle;

[0059] A small hole is arranged on the end surface or the bottom surface of the closed end of the ink tank as a nozzle, and no additional nozzle plate is needed.

Embodiment 3

[0061] The ink tank is a tank body closed at both ends, wherein:

[0062] A window is opened at one end of the ink tank on the flexible diaphragm and the support to form an ink inlet; or, a through hole is opened at the bottom of one end of the ink tank to form an ink inlet;

[0063] The end surface or the bottom surface of the other end of the ink tank is provided with a small hole as a nozzle;

[0064] There is a small hole on the end surface or the bottom surface of the other end of the ink tank as a nozzle, and no additional nozzle plate is needed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com