Rotary ornithopter with springs

A flapping-wing aircraft, right-rotating technology, applied in the field of flapping-wing aircraft, can solve the problems of low efficiency, high requirements for flapping-wing fatigue strength, difficult lift and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

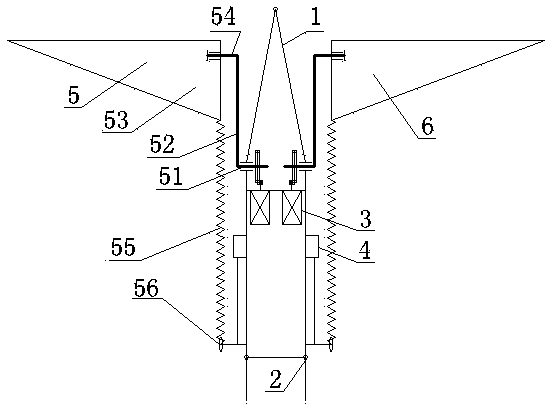

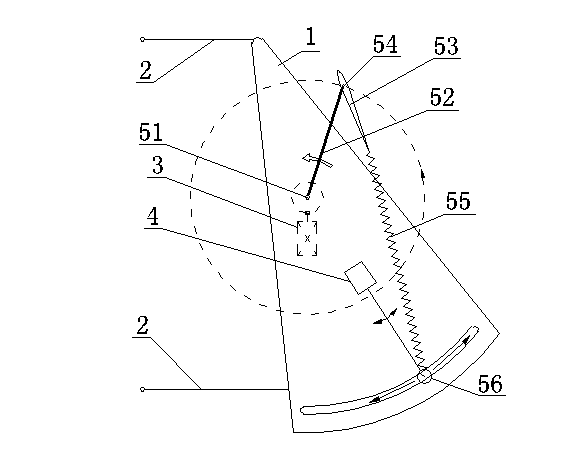

[0013] now attached figure 1 And attached figure 2 The present invention is illustrated by way of example: a spring-loaded rotary flapping-wing aircraft includes a fuselage 1, landing gear 2, an energy system 3, a control system 4, a left-rotating flapping wing 5 and a right-rotating flapping wing 6. Energy system 3 includes two identical motors, lithium batteries for easy charging, two sets of identical reduction gear sets and speed regulating devices; control system 4 includes radio remote control transmitters, receivers and steering gear; left-rotating flapping wings 5 and right The rotating flapping wings 6 have the same structure, and they are respectively symmetrically arranged on the left and right sides of the fuselage 1 and are respectively driven by two identical motors to provide thrust. The aircraft can vertically lift and hover, and has good maneuverability.

[0014] Left rotation flapping wing 5 is made up of left main shaft 51, left turning arm 52, left wing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com