Gap eliminating device and seamless splicing display device

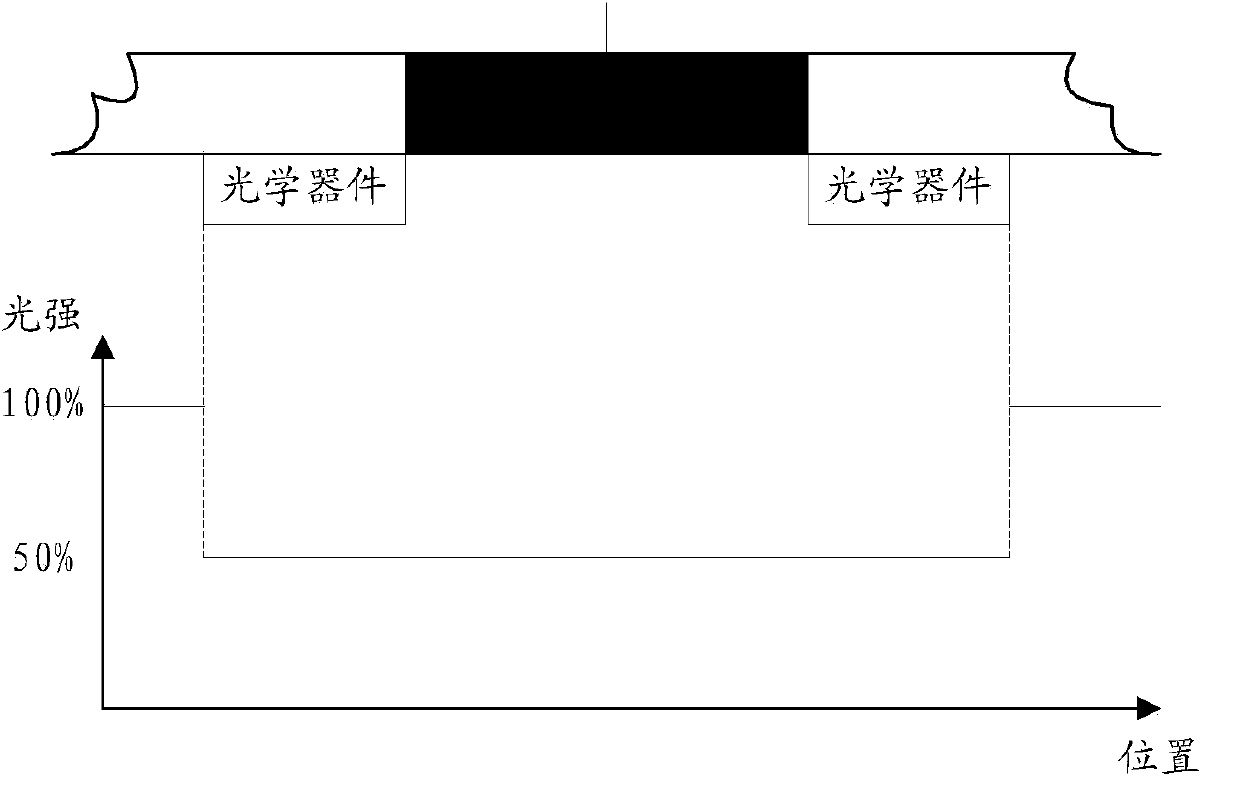

A technology for eliminating seams and display areas, applied in the direction of identification devices, instruments, etc., can solve the problems of sudden changes in light intensity at seams, affecting the effect of splicing display, and unable to achieve smooth transition of light emitted from the LCD frame area and light emitted from the display area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

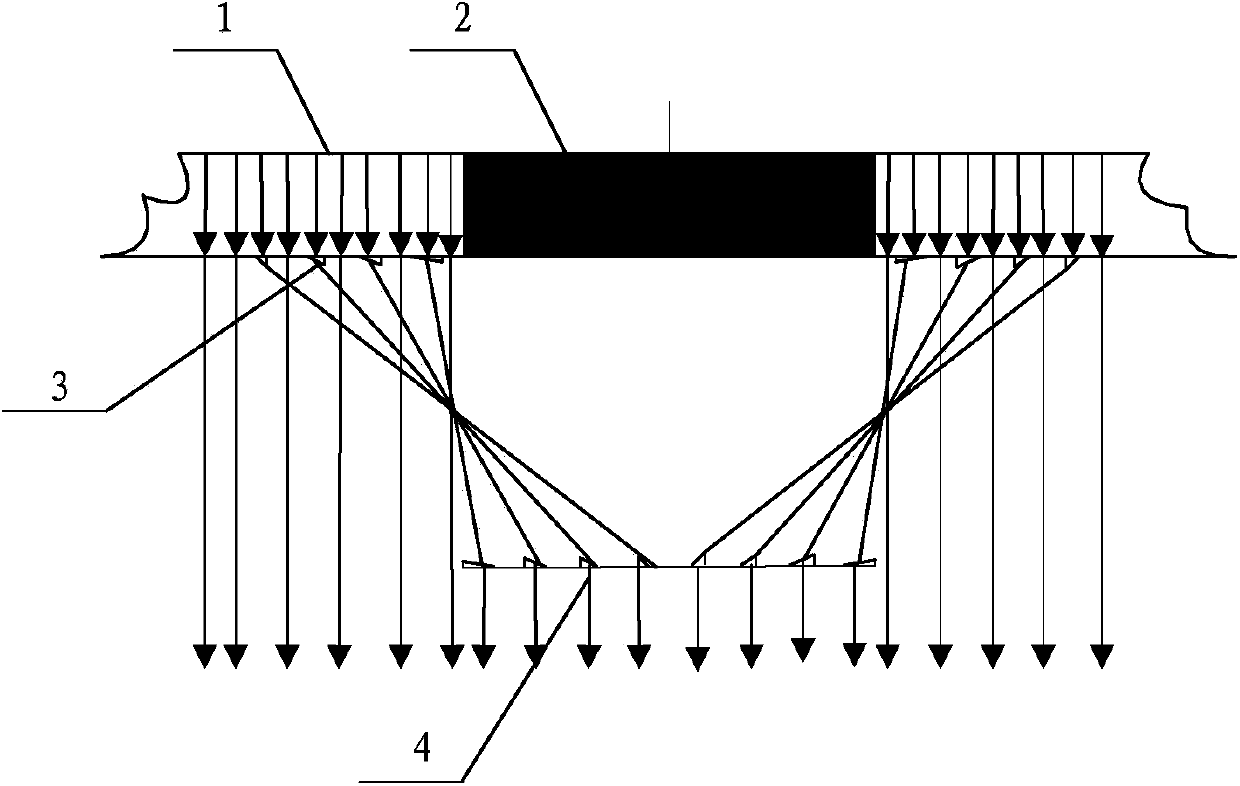

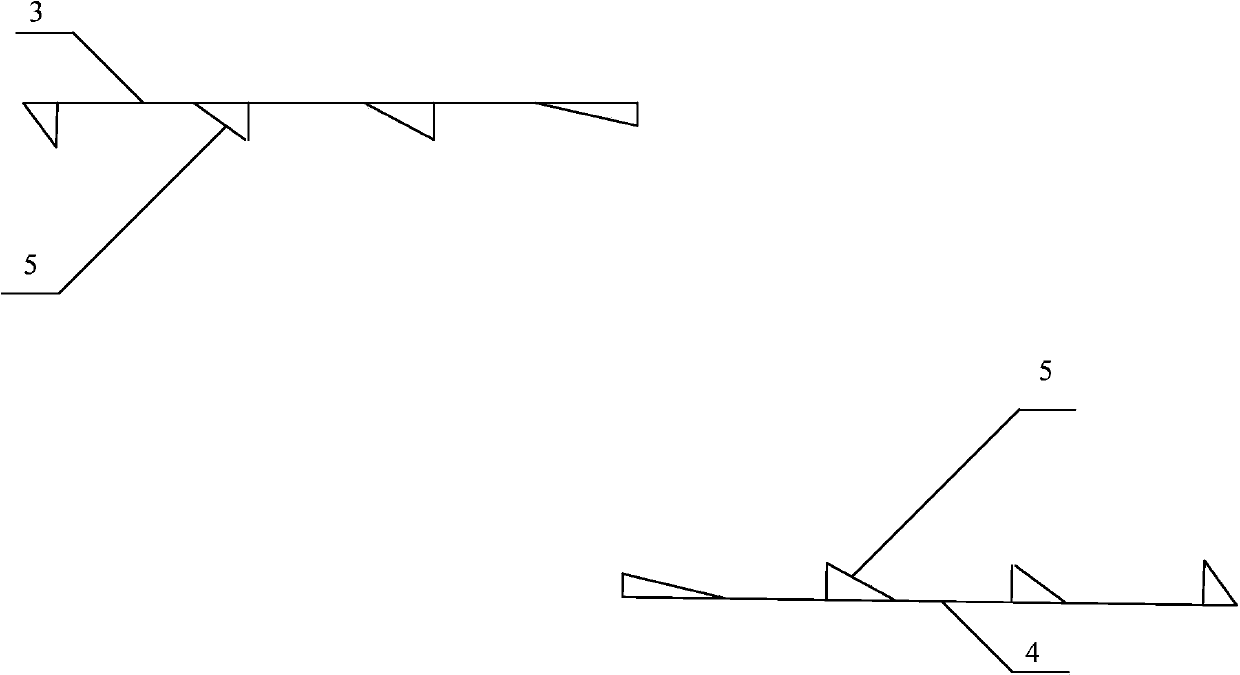

[0027] Refer to 2, which is a schematic diagram of the principle of Embodiment 1 of the seam elimination device of the present invention. see image 3 Shown is a schematic structural view of Embodiment 1 of the seam eliminating device of the present invention.

[0028] Such as figure 2 , image 3 As shown, the anti-seam device of Embodiment 1 includes a first optical assembly 3 arranged in front of the display area 1 of the display screen and a first optical assembly 3 arranged in front of the frame area 2 of the display screen and corresponding to the first optical assembly 3 second optical assembly 4;

[0029] The widths of the first optical assembly 3 and the second optical assembly 4 are consistent with the width of the frame area 3, and both the first optical assembly 3 and the second optical assembly 4 include a plurality of first deflectors 5;

[0030] The first deflectors 5 of the first optical assembly 3 and the second optical assembly 4 are all arranged in a dir...

Embodiment 2

[0046] Refer to 5, which is a schematic diagram of the principle of Embodiment 2 of the seam elimination device of the present invention. see Figure 6 As shown, it is a structural schematic diagram of Embodiment 2 of the seam eliminating device of the present invention.

[0047] Such as Figure 5 , Figure 6 As shown, the anti-seam device in Embodiment 2 includes a third optical assembly 6 arranged in front of the display area 1 of the display screen and a first optical assembly 6 arranged in front of the frame area 2 of the display screen and corresponding to the third optical assembly 6 Four optical components 7;

[0048] The widths of the third optical assembly 6 and the fourth optical assembly 7 are consistent with the total width of the adjacent spliced frame areas of the frame area 3, and the third optical assembly 6 and the fourth optical assembly 7 each include a plurality of second deflectors 8;

[0049] The second deflection members 8 of the third optical ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com