Apparatus for coating optical fiber

A cladding and optical fiber technology, which is applied in the field of cladding forming devices for optical fibers, can solve the problems of not considering temperature effects, weak light, and inability to re-form cladding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

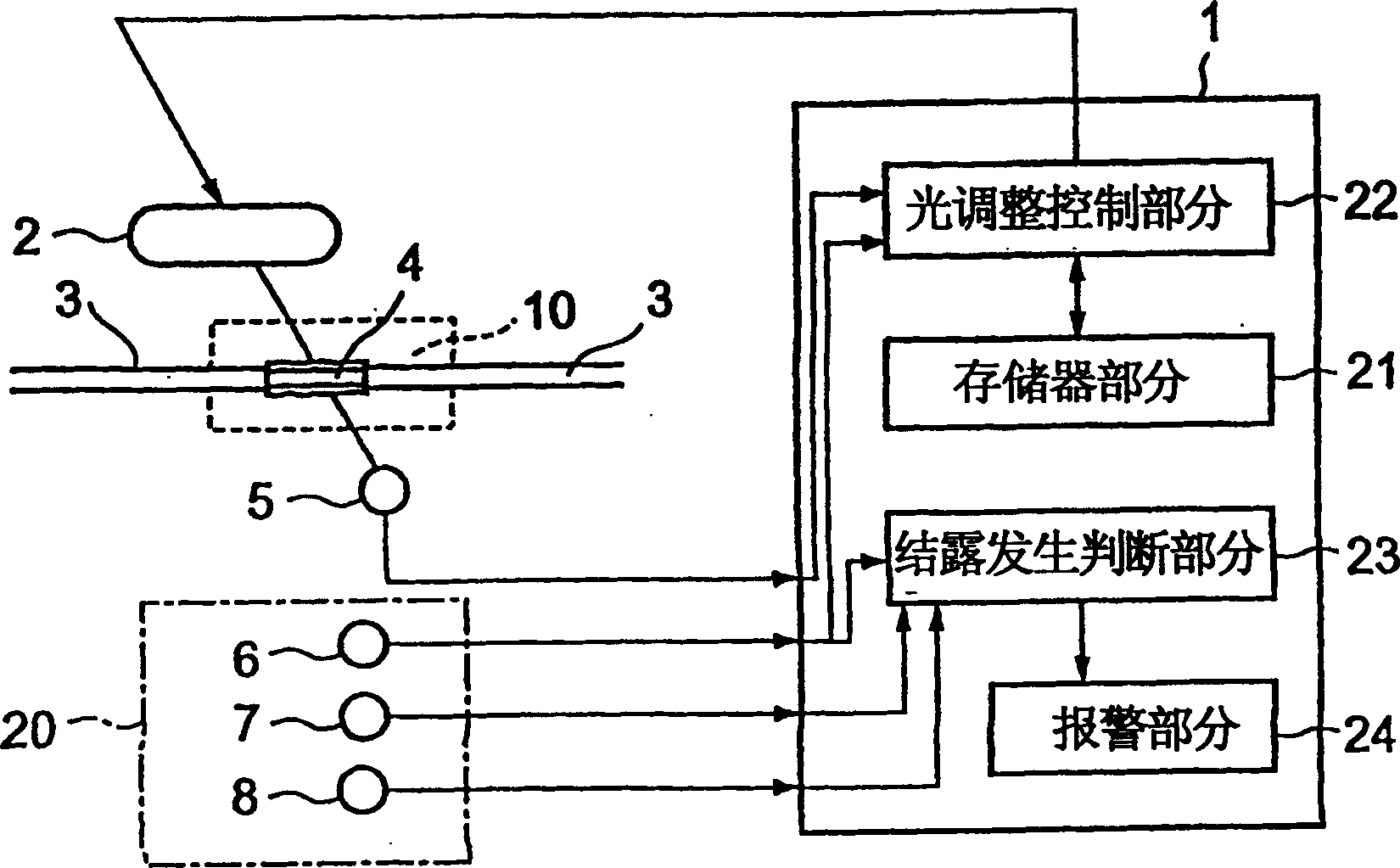

[0016] The present invention will be described in detail below on the basis of embodiment examples by referring to the accompanying drawings. In the following description of the examples of embodiments of the present invention, the same parts in the examples are denoted by the same reference numerals, and their repeated descriptions are omitted or simplified. figure 1 An example embodiment of the optical fiber cladding forming apparatus in the present invention will be described.

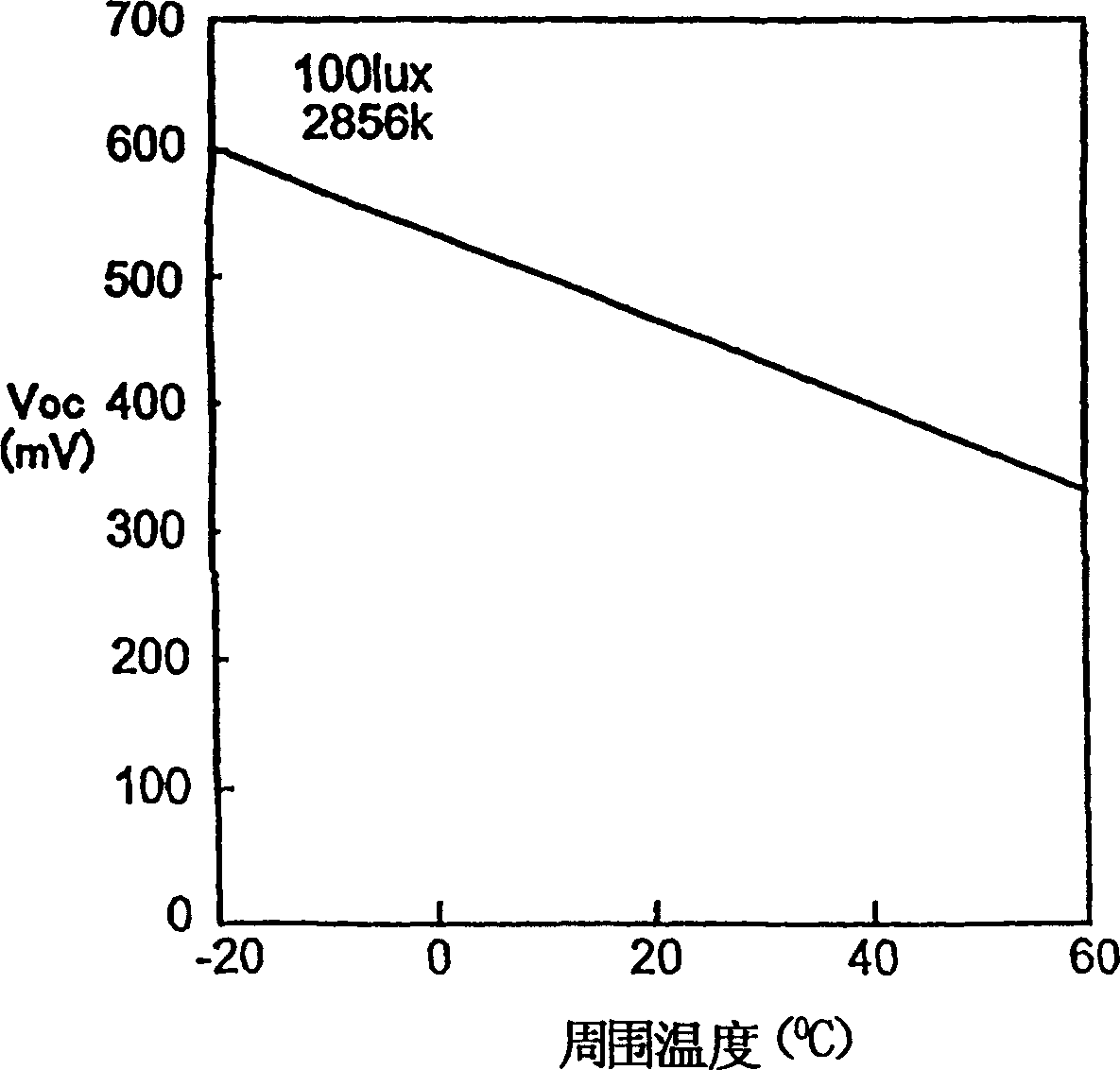

[0017] The coating forming means in this embodiment example is a recoverer having a light source 2 and a light receiver 5 similarly to the recoverer in the conventional example. This embodiment example is characterized by employing an environment sensor 20 for detecting the temperature of the environment including at least the temperature in the installation area of the light source 2 and the light receiver 5 . In addition, this embodiment example is also characterized in that a light output con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com