Electric operating mechanism and protective baffle with hidden protective baffle

A technology of electric operating mechanism and protective baffle, applied in the direction of protection switch operation/release mechanism, parts and circuits of protection switch, etc., can solve the problem of not overcoming the dust pollution of the electric operating mechanism, so as not to be easy to dust pollution, avoid dust pollution, etc. Short circuit phenomenon, the effect of preventing foreign objects from falling in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

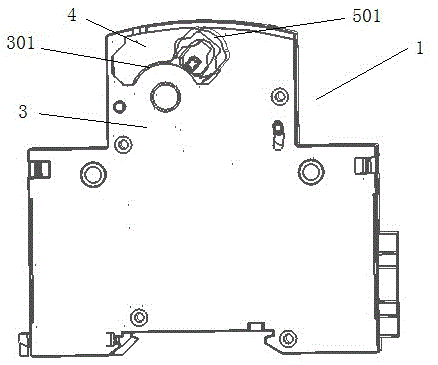

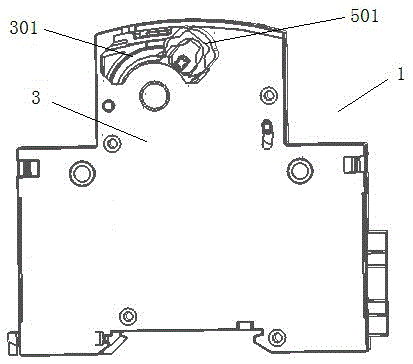

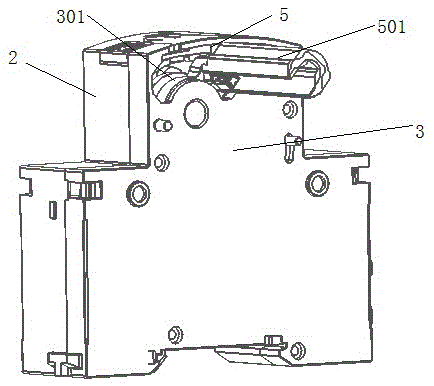

[0034] Such as figure 1As shown, it is the electric operating mechanism with hidden protective baffle of the present invention, and the parts and components located in the housing 2 cannot be seen from this direction, and in figure 2 , 3 It is different in the middle, without installing the protective baffle 4, you can see the internal parts, including the handle structure 5 and the rotating shaft 6, as well as the shell 2 and the cover plate 3, almost all the parts are included in the shell In the body, it is covered by the cover plate 3. The handle structure 5 includes a handle 501, a rotating disk 503 and a coupling part 502. The rotating disk 503 has a shaft hole 5031 for installing the rotating shaft 6. Correspondingly, a shaft is also provided inside the support seat. Hole 801, axle hole 5031,801 are used for installing rotating shaft 6, as image 3 As shown, the handle 501 passes through the installation window 301 of the cover plate 3 and is sequentially connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com