A kind of preparation method of superhydrophobic polyethylene fiber film

A polyethylene fiber, super-hydrophobic technology, applied in spinning solution preparation, textile and papermaking, non-woven fabrics and other directions, can solve the problems of high cost, unsuitable for industrial application, long cycle, etc. Short, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the superhydrophobic polyethylene fiber film of this embodiment, the specific operation steps are:

[0030] 1) Preparation of ultra-high molecular weight polyethylene spinning solution: take ultra-high molecular weight polyethylene powder and add it to the organic solvent xylene, and dissolve it at 140°C for more than 10 minutes until the ultra-high molecular weight polyethylene powder is completely dissolved in xylene to obtain Mass concentration is 0.05% ultra-high molecular weight polyethylene solution;

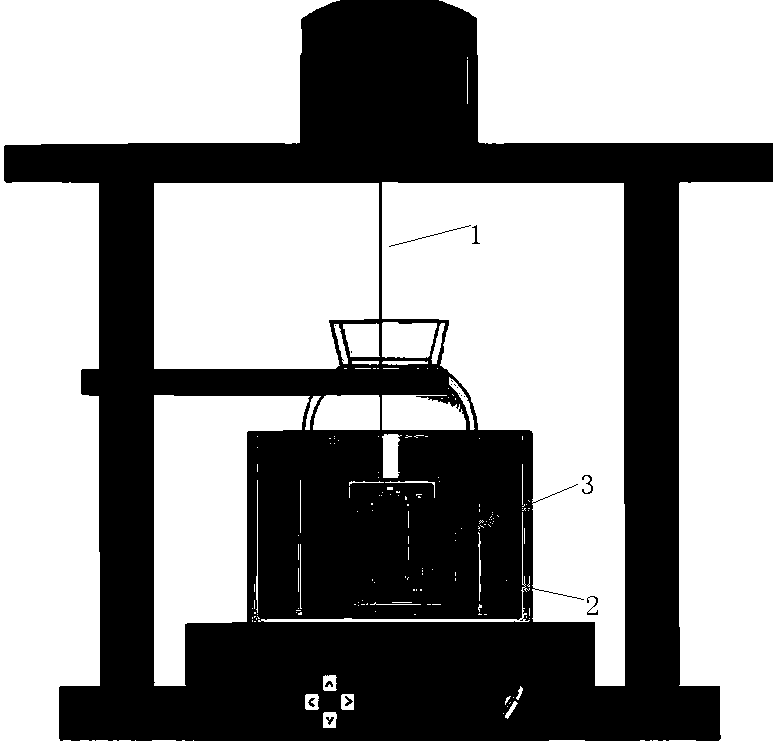

[0031] 2) Spinning and film spinning: such as figure 1 As shown, a stirring rod is set above the oil bath, and two steel wire frames are fixed and fixed symmetrically under the stirring rod, and the ultra-high molecular weight polyethylene solution prepared in step 1) is transferred to the inner diameter of the cylinder placed in the oil bath. In a 35mm necked glass container, the volume of the ultra-high molecular weight polyethylene solu...

Embodiment 2

[0039] The preparation method of the superhydrophobic polyethylene fiber film of this embodiment, the specific operation steps are:

[0040] 1) Preparation of ultra-high molecular weight polyethylene spinning solution: take ultra-high molecular weight polyethylene powder and add it to the organic solvent xylene, and dissolve it at 140°C for more than 10 minutes until the ultra-high molecular weight polyethylene powder is completely dissolved in xylene to obtain A mass concentration of 0.01% ultra-high molecular weight polyethylene solution;

[0041] 2) Spinning and film spinning: set a stirring bar above the oil bath, and connect two steel wire frames symmetrically and symmetrically below the stirring bar, transfer the ultra-high molecular weight polyethylene solution prepared in step 1) to the oil bath, The wire frame is immersed in the ultra-high molecular weight polyethylene solution, the oil bath temperature is set to 110°C, the stirring rate is set to 800r / min, and the co...

Embodiment 3

[0045] The preparation method of the superhydrophobic polyethylene fiber film of this embodiment, the specific operation steps are:

[0046] 1) Preparation of ultra-high molecular weight polyethylene spinning solution: take ultra-high molecular weight polyethylene powder and add it to the organic solvent xylene, and dissolve it at 140°C for more than 10 minutes until the ultra-high molecular weight polyethylene powder is completely dissolved in xylene to obtain Mass concentration is 0.5% ultra-high molecular weight polyethylene solution;

[0047] 2) Spinning and film spinning: set a stirring bar above the oil bath, and connect two steel wire frames symmetrically and symmetrically below the stirring bar, transfer the ultra-high molecular weight polyethylene solution prepared in step 1) to the oil bath, The steel wire frame is immersed in the ultra-high molecular weight polyethylene solution, the oil bath temperature is set at 115°C, the stirring rate is set at 800r / min, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com