Mobile Fast Span

A crossing frame and mobile technology, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems that materials cannot be reused, the influence of surrounding facilities is large, and the crossing frame is not firm, so as to achieve a small footprint, improve the strength of the car body, Reduce the effect of falling and rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

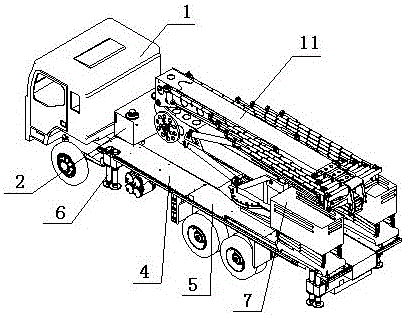

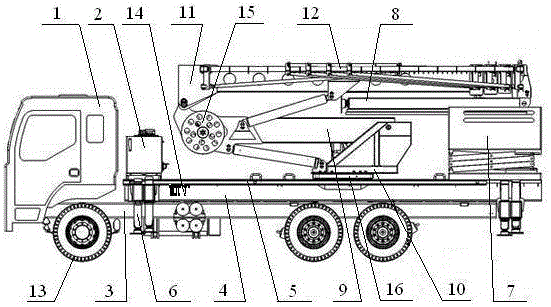

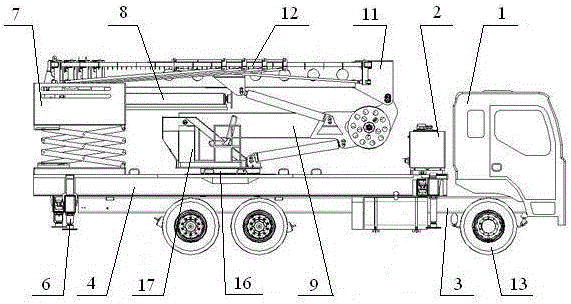

[0033] A mobile fast spanning frame with a structure such as Figure 1~4 Shown, comprise car body, auxiliary frame 4, car body supporting assembly 6, hydraulic lifting platform 7, rotary operation assembly.

[0034] The vehicle body is driven by wheels 13 and includes a cab 1 and a main frame 3 . The driver's cab 1 is located at the front end of the car body and is used to control the overall movement of the straddle frame. The main frame 3 is connected to the rear end of the driver's cab 1 and is a rectangular plate structure.

[0035]The shape of the subframe 4 is basically the same as that of the main frame 3 , the subframe 4 is fixedly arranged on the upper end surface of the main frame 3 , and the hydraulic oil tank 2 is arranged at the front of the subframe 4 . The top surface of the auxiliary frame is embedded with a walking platform 5 . The v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com