A friction power generation device and power generation method including a flexible beating surface

A power generation device and a technology of triboelectrode sequence, applied in the direction of friction generators, etc., can solve the problems of small output function and poor durability of wind power generation devices, etc., and achieve the effects of large current output, improved efficiency, and reduced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

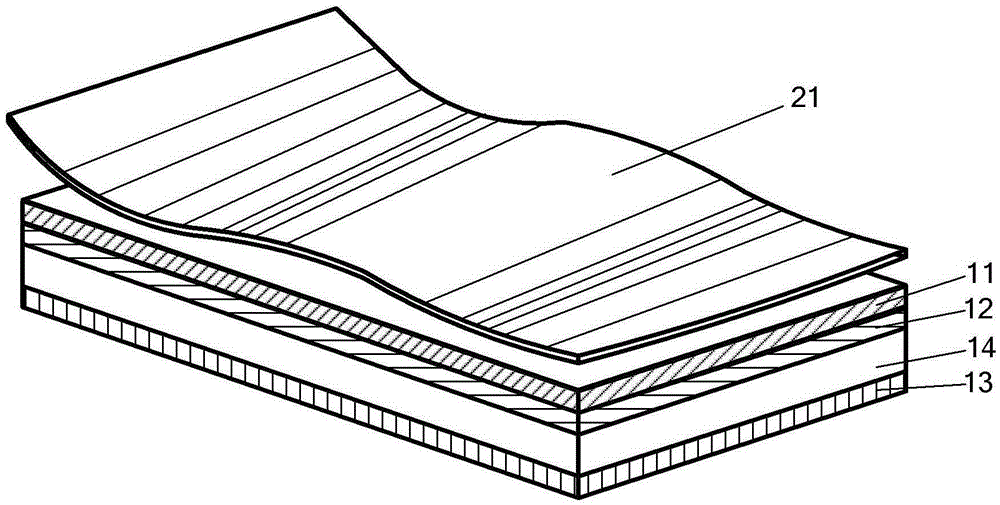

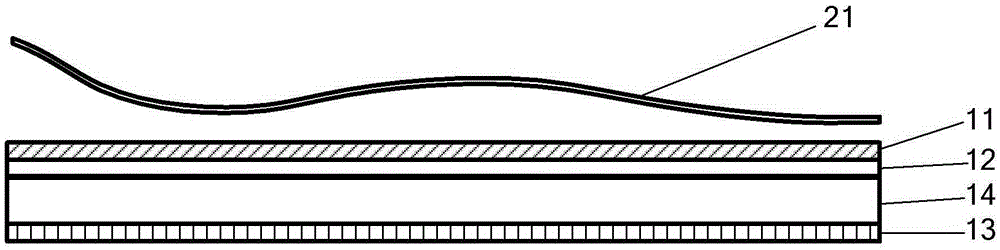

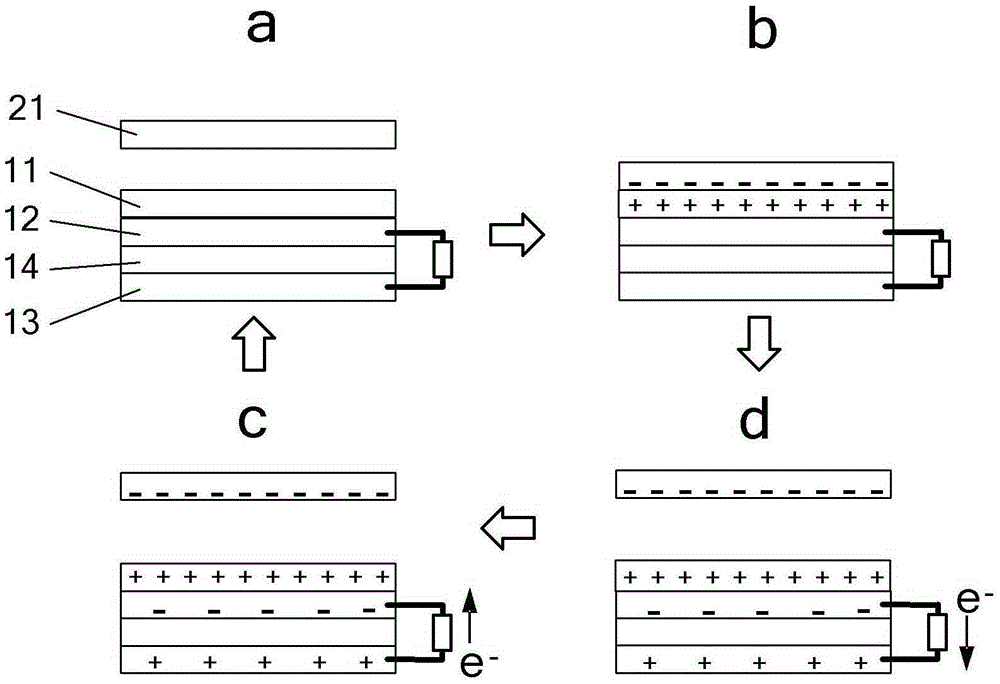

[0042] In order to convert fluid kinetic energy, such as wind energy, into electrical energy, the present invention proposes an innovative power generation device, which utilizes fluid kinetic energy to drive two components to move relative to each other to generate friction-induced charges to generate electricity. These two parts are referred to herein as the first part and the second part.

[0043] In the present invention, we design the flexible second component so that it can be disturbed by external force, especially the fluid flowing through its periphery, so that at least a part of the second surface and at least a part of the first surface produce At least one contact and separation, thereby generating an induced charge on said first and second components. That is, driven by the fluid, the second part slaps the first part, and the beating contact surfaces of the two are respectively referred to as the first surface (of the first part) and the second surface (of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com