A hot core core making method and core making machine

A core making machine and hot core technology, which is applied to molding machines, manufacturing tools, casting and molding equipment, etc., can solve the problems of not making full use of the core making machine and reducing the core making efficiency, so as to improve the core making efficiency and save air circulation. time, waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

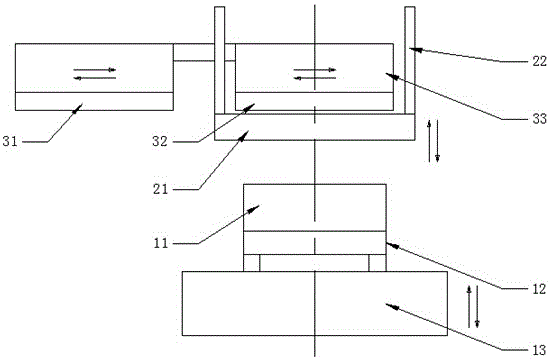

[0047] see figure 1 and figure 2 , as shown in the legend, a core making machine, including a lower core box device, an upper core box device, a sand ejecting core device and a hot core heating device (not shown in the figure), the lower core box device includes the following Core box 11, a lower mobile trolley 12 that can move in the horizontal direction, and a lift table 13 that can move in the vertical direction. The above-mentioned upper core box device includes an upper core box 21 and a lifting mechanism 22 that can move in the vertical direction , the above-mentioned sand-shooting and ejecting core device includes a sand-shooting mechanism 31, a core ejecting mechanism 32 and an upper mobile trolley 33 that can move in the horizontal direction, the lower core box 11 is connected to the lower mobile trolley 12, and the lower mobile trolley 12 is arranged on the lifting workbench 13, the lifting mechanism 22 is connected to the upper core box 21, the sand shooting mecha...

Embodiment 2

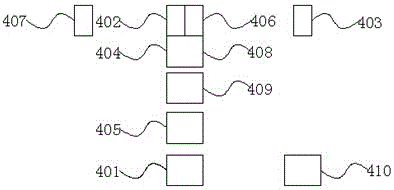

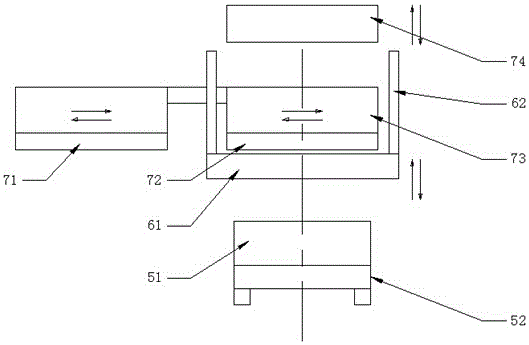

[0062] see image 3 and Figure 4 , as shown in the legend, a core making machine, including a lower core box device, an upper core box device, a sand ejecting core device and a hot core heating device (not shown in the figure), the lower core box device includes the following The core box 51 and the lower mobile trolley 52 that can move along the horizontal direction, the above-mentioned upper core box device includes an upper core box 61 and a lifting mechanism 62 that can move along the vertical direction, and the above-mentioned sand shooting device includes a sand shooting mechanism 71, A top core mechanism 72, an upper mobile trolley 73 that can move horizontally, and a pressing head 74 that can move vertically, the lower core box 51 is connected to the lower mobile trolley 52, and the lifting mechanism 62 is connected to the upper core On the box 61, the upper core box 61 is set opposite to the lower core box 51, the sand shooting mechanism 71 and the core pushing mech...

Embodiment 3

[0078] The rest is the same as the second embodiment, except that the above-mentioned upper mobile trolley is provided with an independent jacking mechanism and is not connected with the above-mentioned pressing head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com