Patents

Literature

40results about How to "Improve core making efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

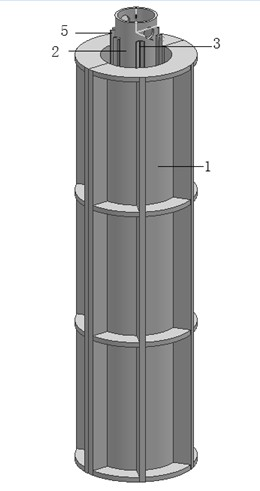

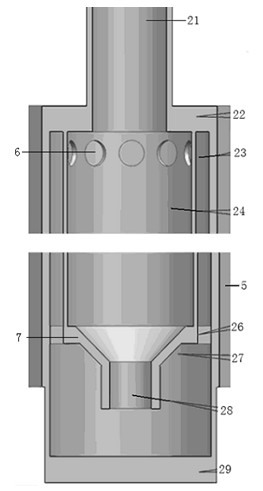

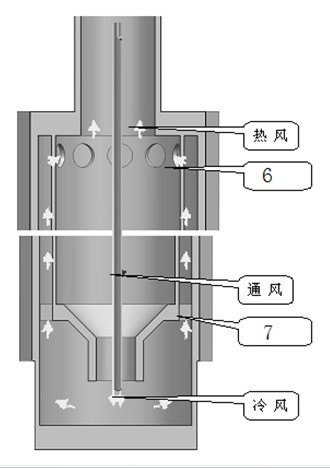

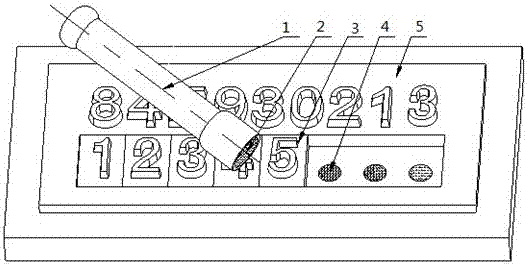

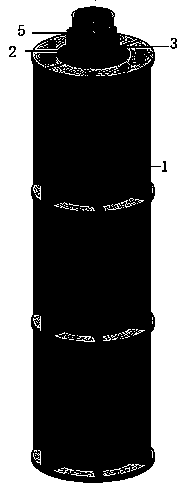

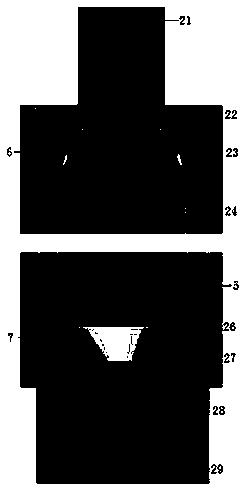

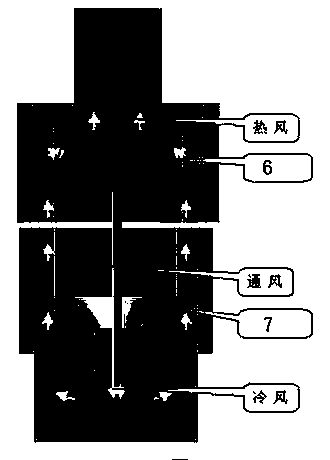

Ventilation cooling sand core for casting cylinder jacket of diesel engine and manufacturing method thereof

ActiveCN102430717APrevent peelingImprove core making efficiencyFoundry mouldsFoundry coresCold airSheet steel

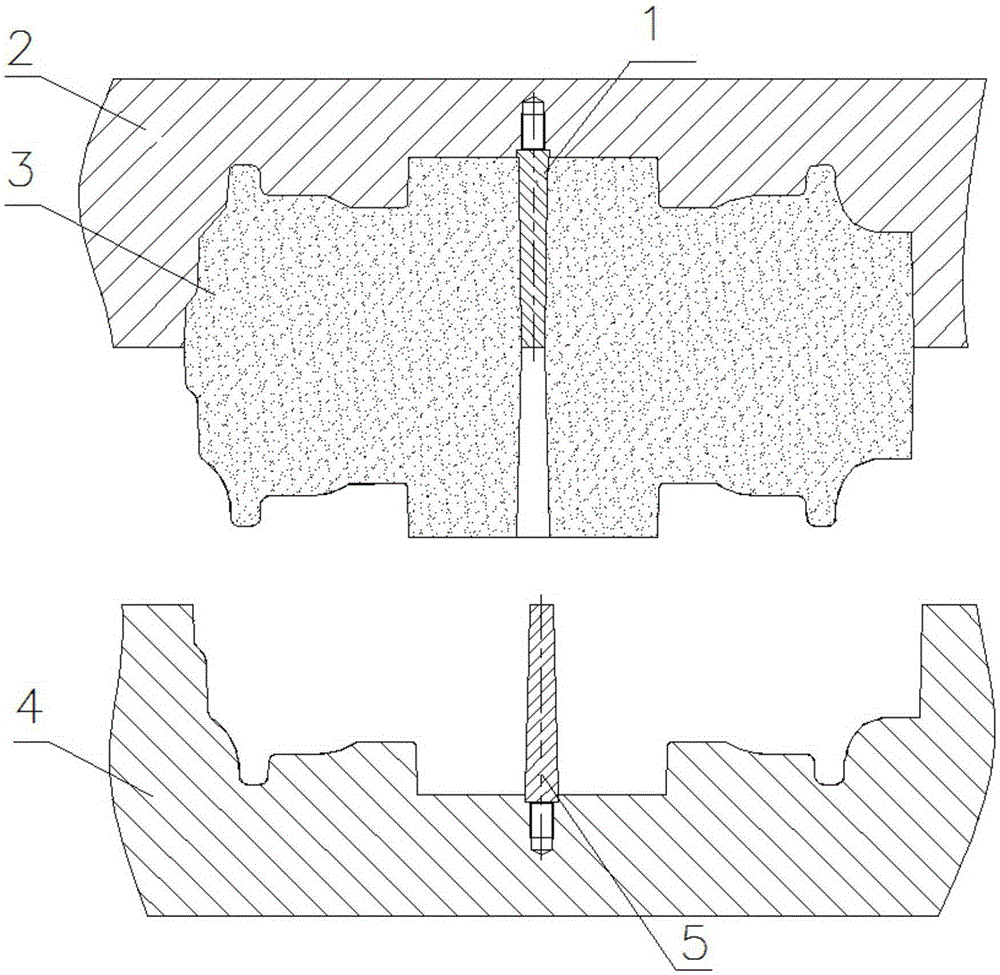

The invention discloses a ventilation cooling sand core for casting a cylinder jacket of a diesel engine. The ventilation cooling sand core comprises a core shell, a core bar and a ventilation rope, wherein the core bar comprises a sleeved inner steel pipe and a longer outer steel pipe; the upper ends of the inner steel pipe and the outer steel pipe are fixed together with a first ring-shaped steel plate; multiple upper vent holes are arranged at the upper end of the inner steel pipe; the lower end of the inner steel pipe is fixed together with the upper surface of a second ring-shaped steel plate; the inner opening of the second ring-shaped steel plate is downward connected with a hopper-shaped conical steel pipe and provided with multiple lower vent holes; a bottom sealing plate is fixed at the lower end of the outer steel pipe; a cold air cavity is formed among the outer steel pipe, the bottom sealing plate and the hopper-shaped conical steel pipe; the central inner ring of the first ring-shaped steel plate is upward fixedly provided with a first steel pipe; the first steel pipe, the inner steel pipe and the hopper-shaped conical steel pipe form an insertion channel of a cooling ventilation pipe; and the space among the lower vent holes, the inner steel pipe and the outer steel pipe and an upper air outlet form a hot air channel. According to the invention, the core manufacturing efficiency is improved, the qualification rate of the cylinder jacket is increased, the quality of the cylinder jacket is stabilized, and the production cost is lowered.

Owner:HUDONG HEAVY MACHINERY

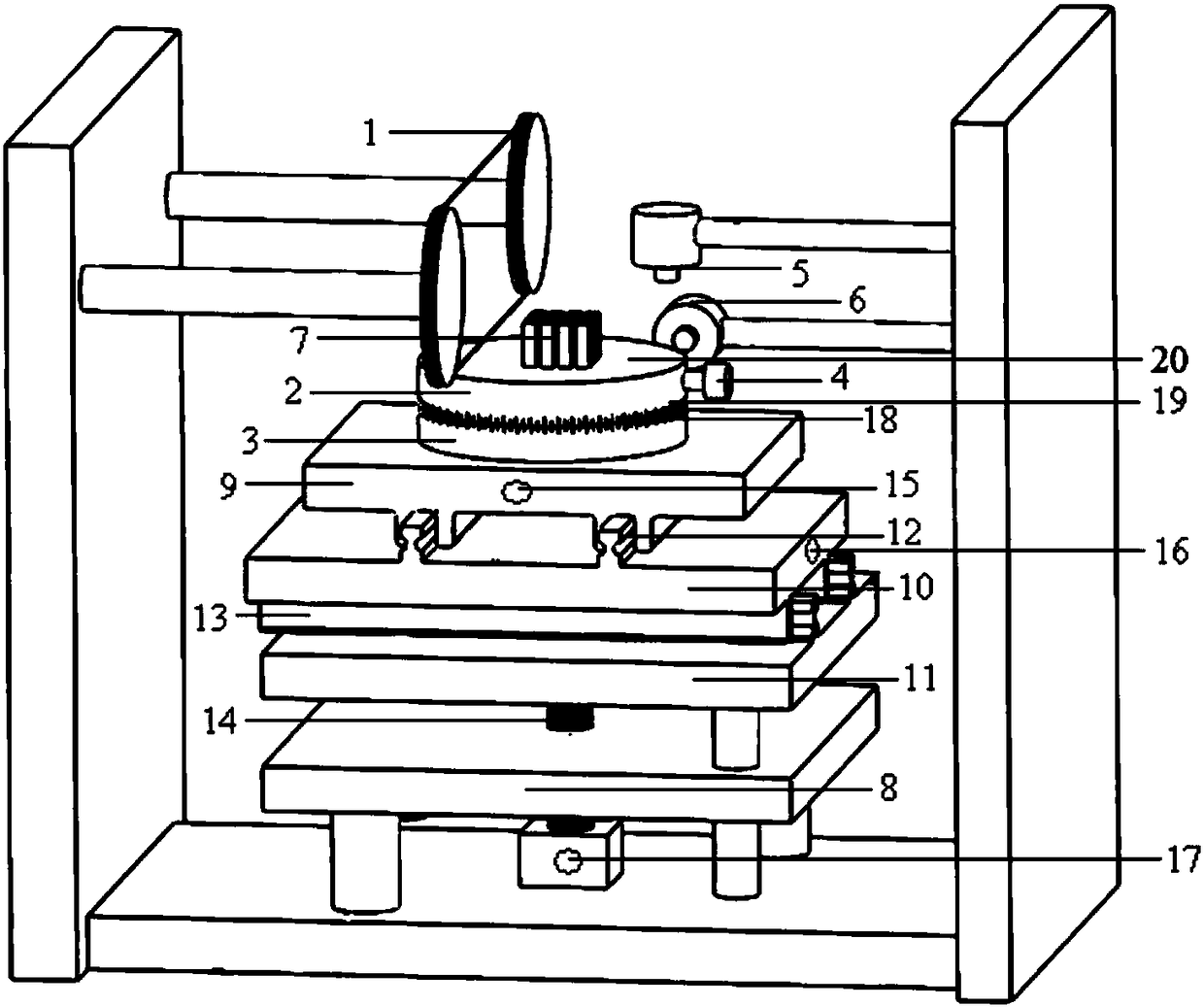

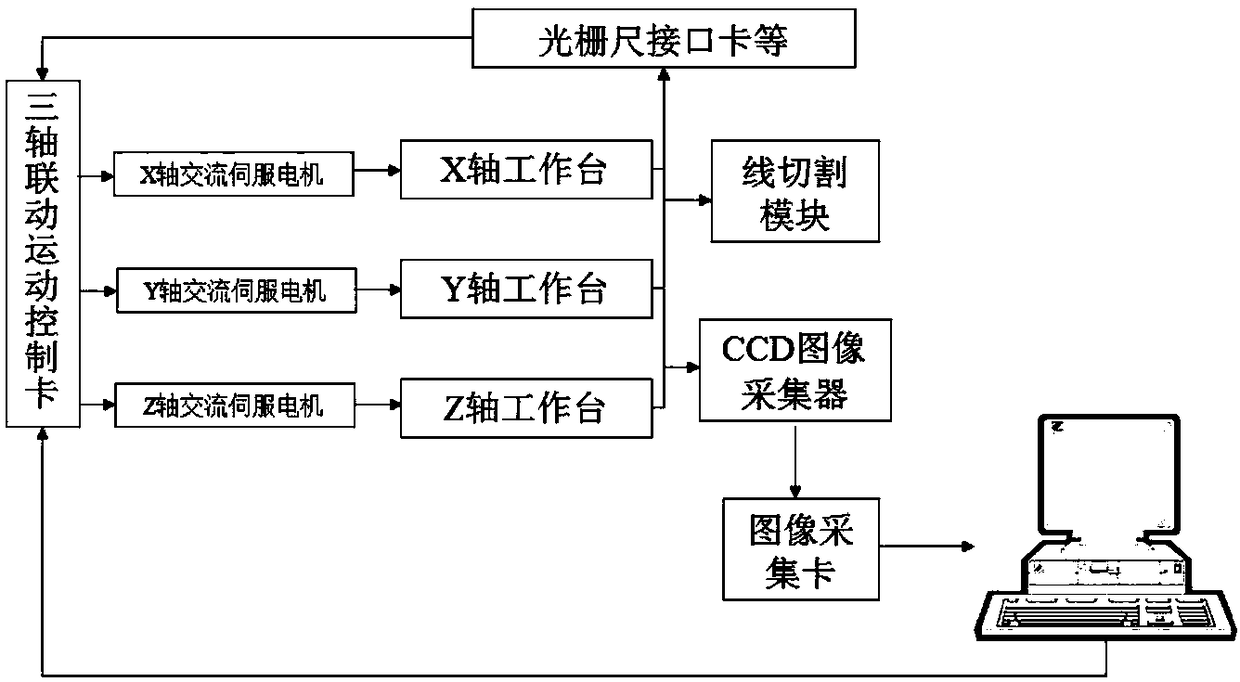

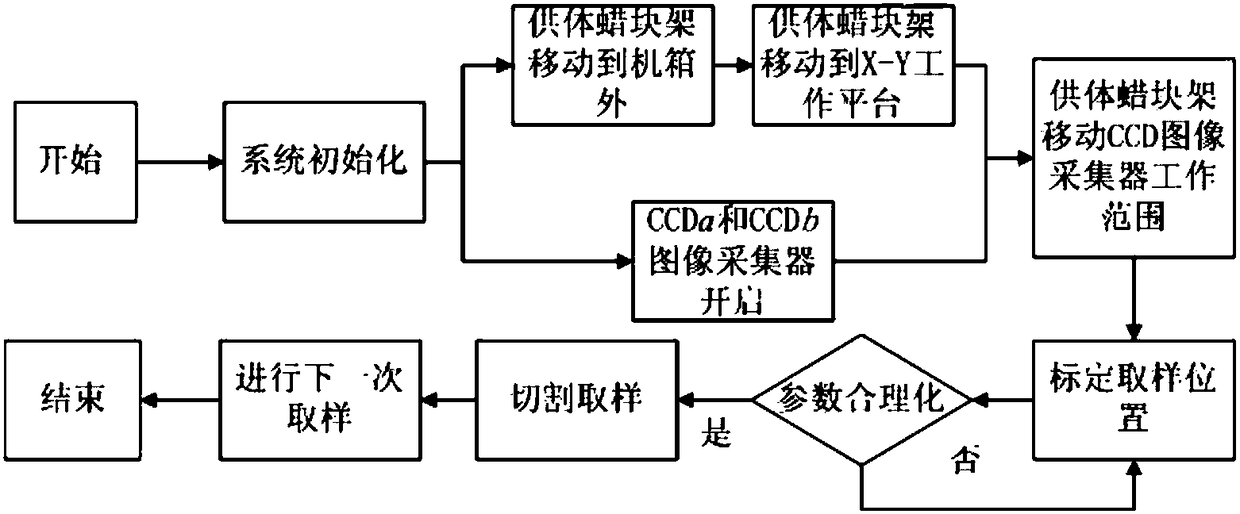

Tissue chip making system based on image recognition and positioning and chip making method thereof

PendingCN108414325AHigh speed acquisitionHigh speed savePreparing sample for investigationNumerical controlEngineering

The invention discloses a tissue chip making system based on image recognition and positioning and a chip making method thereof. The chip making system comprises a cutting system and a computer control system; the cutting system comprises a numerical control cutting machine, an XYZ axis translation work table, a 360-degree-rotation rotary table, a receptor wax block frame, a freezing table and animage recognition and positioning module. The chip making process of the chip making system comprises sample placing, sample position identification, tissue sample image acquisition, tissue sample image processing, setting of cutting parameters, cutting of a tissue sample, tissue chip information identification and storage, and obtaining of the tissue chip with traceability of information. The method obtains a chip taking area by visual identification, has the advantages of high degree of automation and high work efficiency, through linear cutting of the tissue sample, tissue damage is effectively reduced, and the chip taking efficiency and success rate are improved; a database is established for management of the information of the tissue chip, so as to be easy to follow-up queries.

Owner:THE THIRD XIANGYA HOSPITAL OF CENT SOUTH UNIV

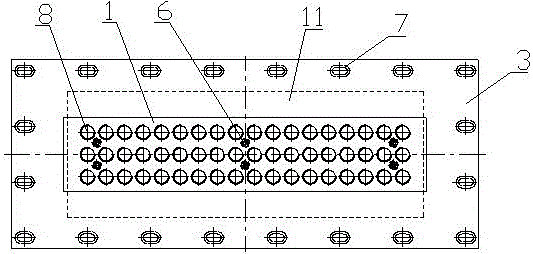

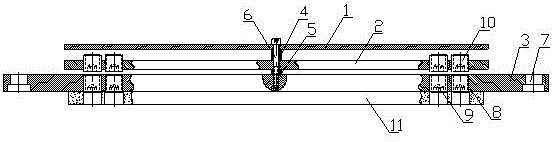

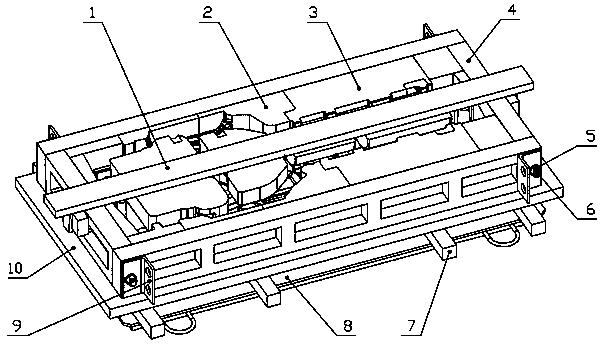

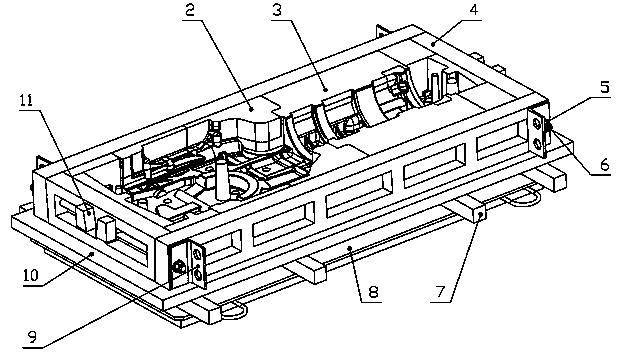

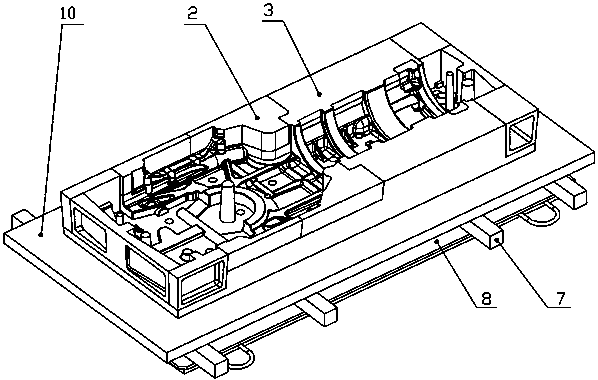

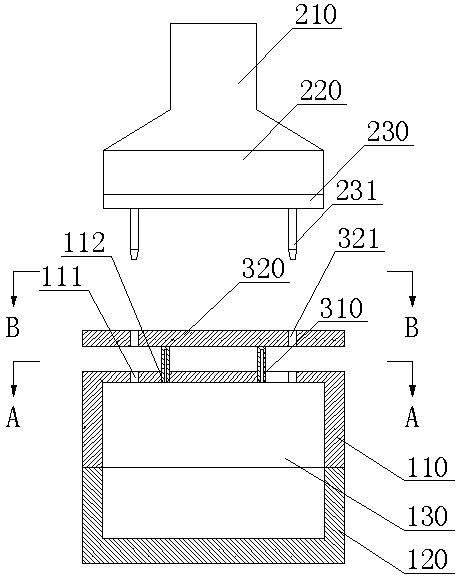

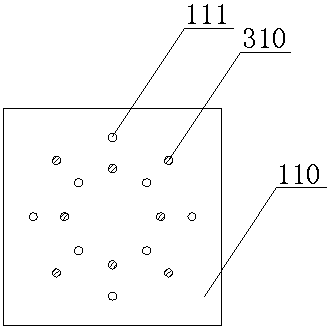

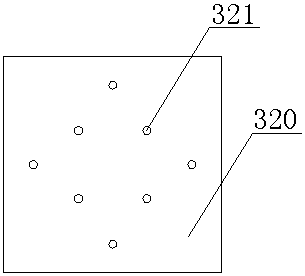

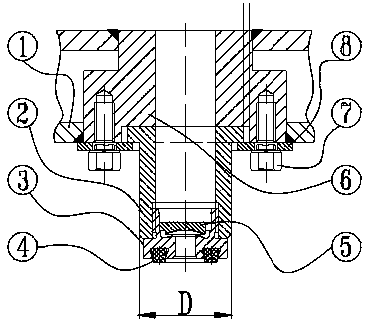

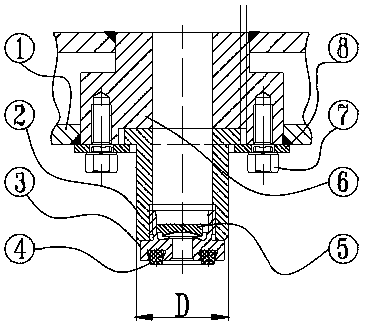

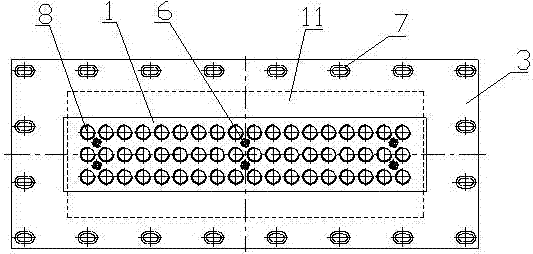

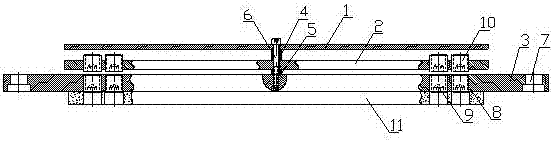

Universal sand shooting plate

ActiveCN105798244ASand shooting pressure can be adjustedImprove core qualityMoulding machinesStructural engineeringManufacturing quality

The invention relates to a universal sand shooting plate. The universal sand shooting plate is characterized in that the universal sand shooting plate sequentially comprises a limiting baffle (1), a support (2) and a sand shooting plate main board (3) from top to bottom; a gap exists between the limiting baffle (1) and the support (2); a gap exists between the support (2) and the sand shooting plate main board (3); a circle of connection bolt holes (7) are formed in the edge of the sand shooting plate main board (3) which is provided with a plurality of sand shooting holes (8) arranged in an array manner; the support (2) is provided with screw holes with the positions corresponding to those of the sand shooting holes in the sand shooting plate main board (3); closing screwed plugs (9) are rotationally arranged in the sand shooting holes (8); and adjusting screwed plugs (10) are formed in the screw holes of the support (2). The universal sand shooting plate has the beneficial effects the sand shooting pressure can be adjusted, the core manufacturing quality and the production efficiency are improved, the mold opening time is saved, and cost is saved.

Owner:江阴机械制造有限公司

Method for producing casting cold-box resin

The invention relates to a method for producing resin, and particularly relates to a method for producing casting cold-box resin. The method comprises the following steps: adding dissolved industrial phenol to a reaction kettle; starting an agitator; adding solid paraformaldehyde, a regulator and 0.08-0.12% of metal ion catalyst; opening a steam valve, slowly heating up, and heating up to 105 DEG C within 40-50 minutes; keeping constant temperature at 105-108 DEG C for 30 minutes; heating up to 112 DEG C within 10-20 minutes, and keeping constant temperature at 112-115 DEG C for 50 minutes; continuing to heat up and dewatering under normal pressure after heat preservation is finished; timing constant temperature when the temperature inside the kettle ascends to 120 DEG C, and keeping constant temperature at 120-123 DEG C for 30 minutes; after constant temperature is finished, vacuumizing and continuing to dewater; stopping dewatering when the total dewatering amount achieves 60% of formaldehyde amount; adding a polar dibasic acid ester, nonpolar high-boiling point solvent oil and a modifier; agitating for 60 minutes; adding an enhancer when cooling to below 40 DEG C; evenly agitating, detecting and packaging. The casting cold-box resin which is low in viscosity, and high in casting sand strength, can be used for a long period of time, and meets core-making production in batches is provided by the invention.

Owner:共享新材料(山东)有限公司

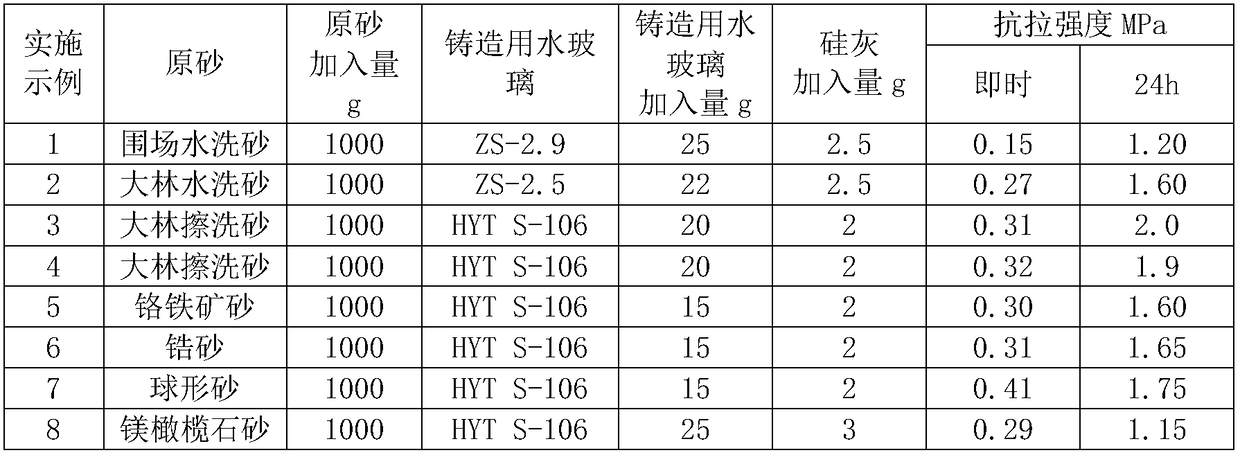

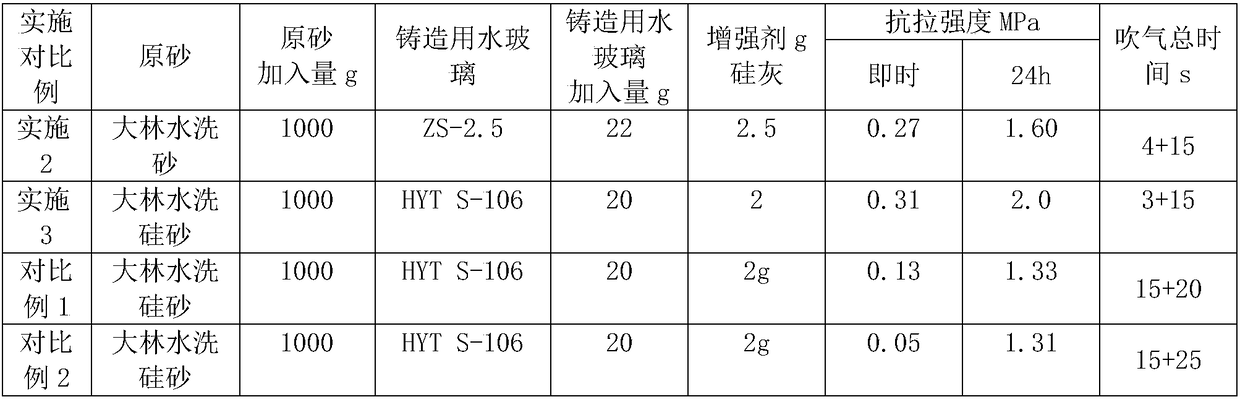

Efficient core manufacturing method for blowing and hardening sodium silicate-bonded sand

PendingCN109420743AQuality assuranceReduce consumptionFoundry mouldsFoundry coresLower limitProduct gas

The invention relates to the technical field of casting, in particular to an efficient core manufacturing method for blowing and hardening sodium silicate-bonded sand. Before core manufacturing, a dieis heated to 30-100 DEG C firstly, then roughing sand, sodium silicate-bonded sand for casting and a reinforcing agent are mixed through a sand mixing machine, a core sand mixture is manufactured, then the core sand mixture is injected into the die through a core injection machine, CO2 is blown firstly, then the gas is compressed, the gas is blown into a cavity of the die, blowing and hardening are carried out, CO2 blowing pressure is 0.05-0.6 Mpa, time for blowing is 2S-120S, blowing compressed gas pressure is 0.05-0.7 Mpa, blowing time is 5S-120S, lower limit is adopted for blowing time ofsmall cores, blowing time is prolonged properly for large cores, and die is opened after blowing is finished. According to the method, the addition amount of the sodium silicate-bonded sand is small,die opening strength is high, blowing time is short, the core manufacturing speed is high, toxicity and odor are avoided, the gas generation amount of sand cores is small, the quality of castings is improved beneficially, and the labor condition is improved.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

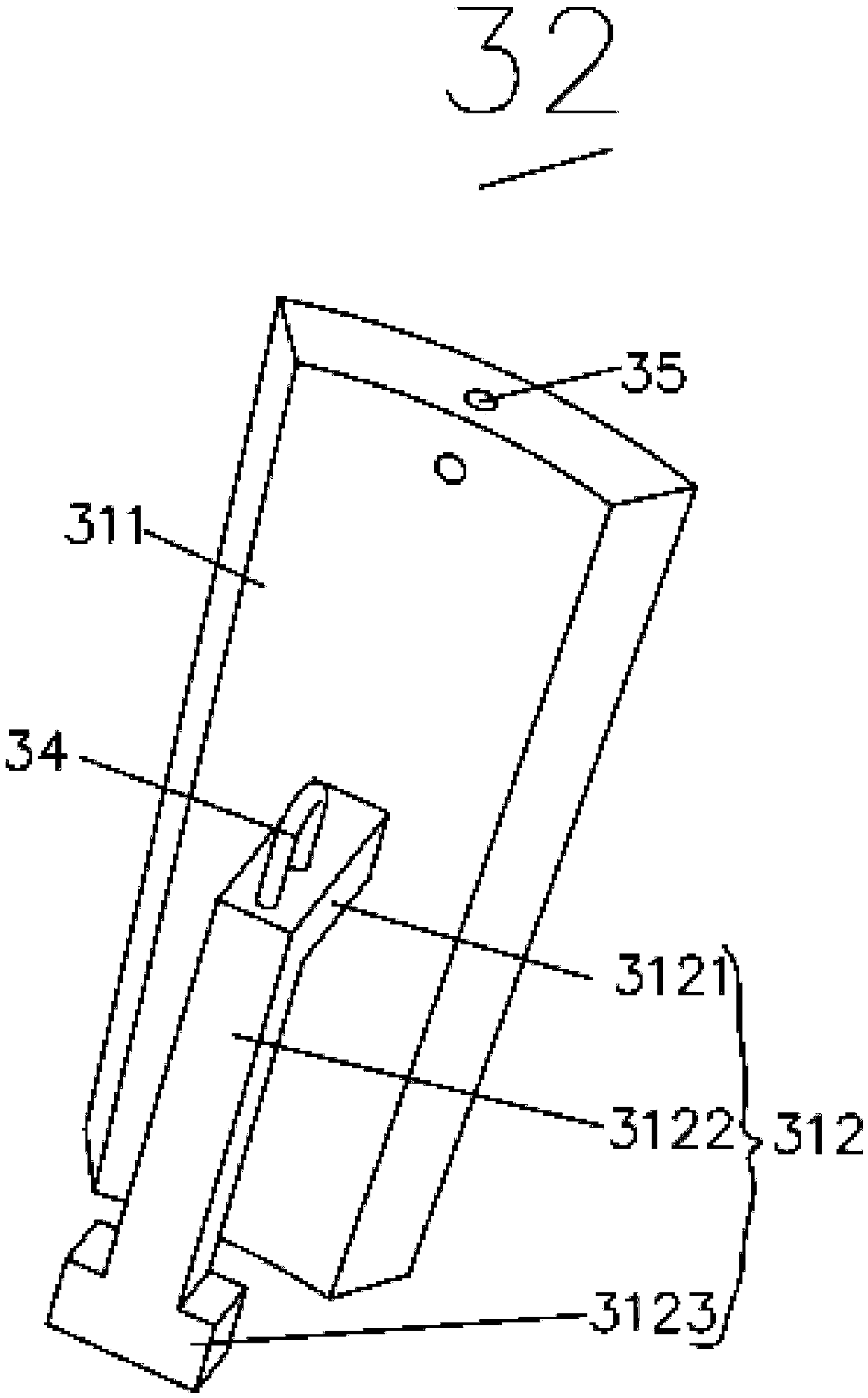

Multifunctional locking mechanism for sand core and core manufacturing method

ActiveCN105344947AEffectively fixedEasy to fixFoundry mouldsFoundry coresLocking mechanismEngineering

The invention discloses a multifunctional locking mechanism for a sand core. The mechanism comprises an upper core box and a lower core body, wherein a first core assembly screw hole die pattern is vertically arranged in the upper core box; a second core assembly screw hole die pattern is vertically arranged in the lower core box; at least one groove for locking and fixing the sand core on the upper core box is formed at a position, close to the upper core box, on the first core assembly screw hole die pattern; the first core assembly screw hole die pattern has pattern lifting inclination. With the adoption of the multifunctional locking mechanism for the sand core, the sand core can be well fixed during the die releasing process, and core assembly screw holes can be formed in the die-released sand core. The invention further provides a core manufacturing method using the aforementioned multifunctional locking mechanism for the sand core.

Owner:GUANGXI YUCHAI MASCH CO LTD

Engine cylinder block water channel sand core and preparation process thereof

InactiveCN110560642AGood collapsibilityGood internal cleanlinessFoundry mouldsFoundry coresPhysical chemistryEngineering

The invention discloses an engine cylinder block water channel sand core and a preparation process thereof, and belongs to the technical field of engine part casting. The engine cylinder block water channel sand core is prepared from the following components in parts by weight: 70-80 parts of quartz sand, 20-30 parts of chromite sand, 0.5-1 part of iron oxide powder, 0.75-0.85 part of a rein component I, and 0.75-0.85 part of a rein component II. The engine cylinder block water channel sand core has the following advantages that (1) the sand penetration and veining preventing capacity is high,the molten iron pouring amount of a casting is 350 KG, the pouring temperature is 1380-1400 DEG C, an inner cavity of a water channel is free of the sand penetration and veining defects, collapsibility is good, clearing is easy, and the cleanliness of the inner cavity is good; and (2) the core manufacturing efficiency of a cold-box preparation process is high, a triethylamine catalytic curing process is used, the core manufacturing efficiency is high, and the engine cylinder block water channel sand core is suitable for large-scale production.

Owner:SINO TRUK JINAN POWER

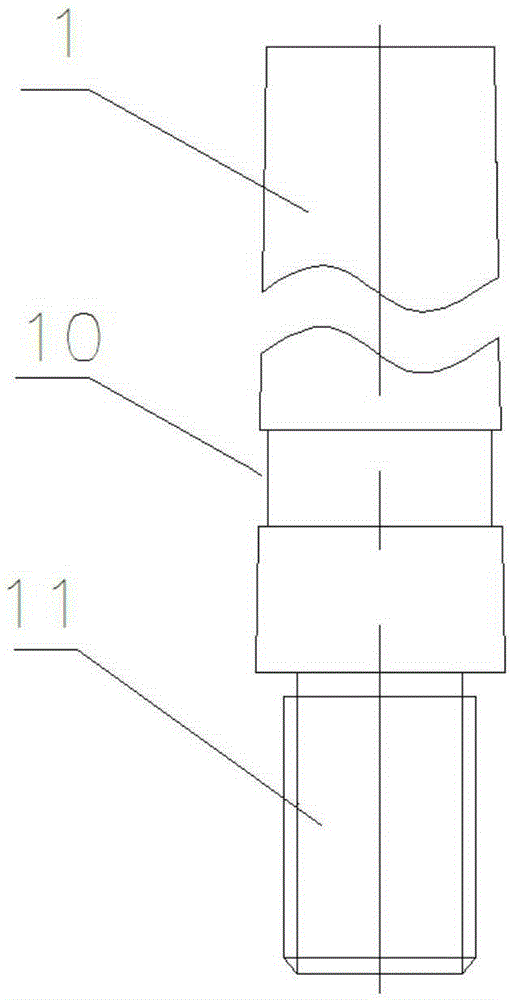

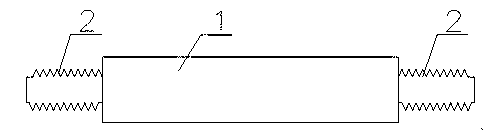

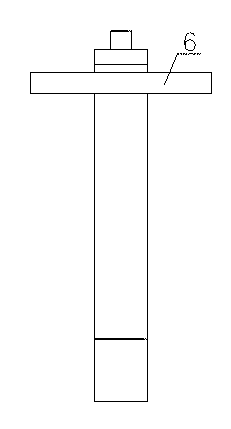

Upward ejection core rod with characteristic of easy replacement

InactiveCN103223461ALow failure rateSolve the problem of easy falling offFoundry mouldsMoulding machinesEngineeringFault rate

The present invention relates to an upward ejection core rod, particularly to an upward ejection core rod for a cold core box mold, wherein the upward ejection core rod has a characteristic of easy replacement. The upward ejection core rod comprises a rod body, wherein both sides of the rod body are processed with external threads, the left end of the rod body and a screw cap form a threaded connection, a string washer is arranged between the screw cap and the rod body, and the right end of the rod body and a nylon rod form a threaded connection. According to the upward ejection core rod, both ends of the upward ejection core rod are additionally provided with the screw cap and the nylon rod, the nylon rod is placed in a easy-wear position, and threaded connection fastening is adopted, such that a fault rate of the upward ejection core rod is substantially reduced, a service life of the core box is prolonged, replacement operation is simple after the nylon rod wears, and a time is saved; and the screw cap is adopted to arrange the upward ejection core rod on the upward ejection core plate so as to solve the problem of easy falling of the upward ejection core rod, such that core box damage caused by the upward ejection core rod due to easy falling can be effectively prevented, a service life of the mold can be prolonged, and core preparation efficiency can be effectively increased.

Owner:WUHU LERUISI INFORMATION CONSULTING

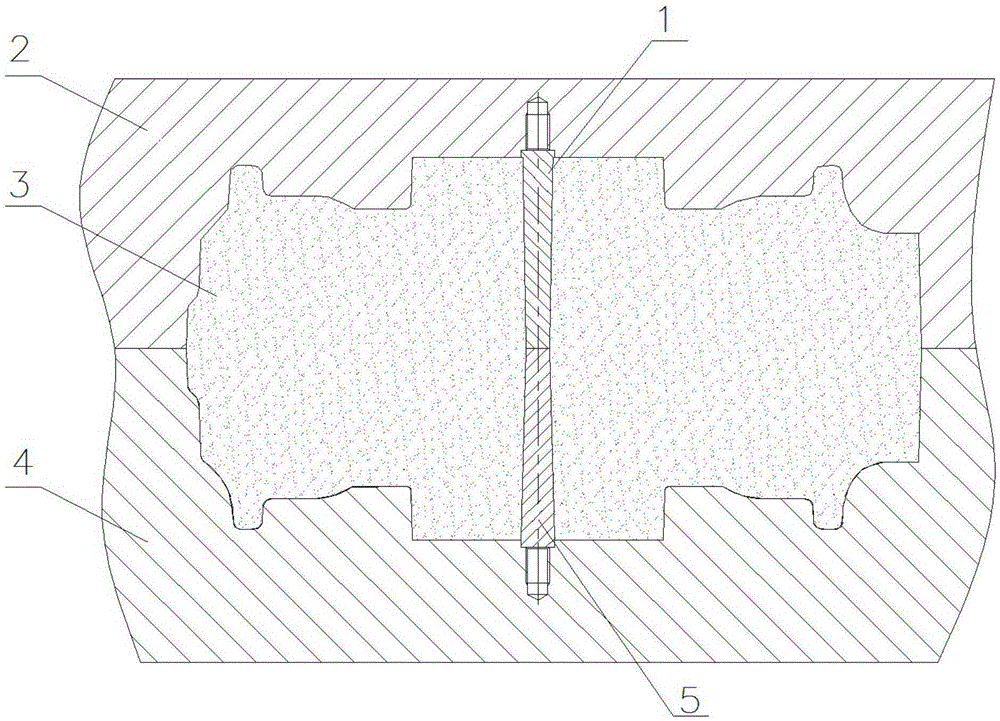

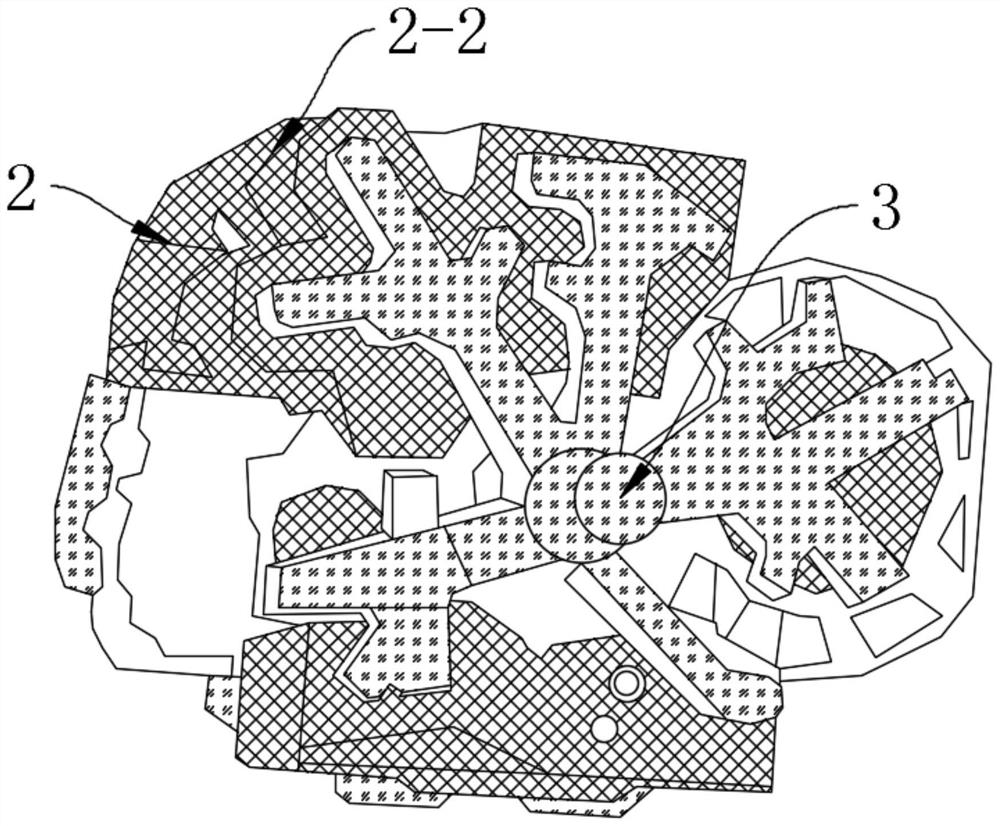

Mould of air cooler sand core in large diesel engine

ActiveCN103736919ASimple structureSolve the problem of smooth demouldingFoundry mouldsFoundry coresEngineeringUltimate tensile strength

The invention discloses a sand core mould of an air cooler sand core in a large diesel engine. The sand core mould comprises an upper core box, a lower core box and a plurality of side surface loose pieces, wherein the upper core box is provided with an upper cavity of the air cooler sand core; a lower cavity of the air cooler sand core, which is matched with the upper cavity of the upper core box and is provided with a plurality of yielding loose piece-shaped surfaces, is formed in the lower core box; the side surface loose pieces are arranged in the yielding loose piece-shaped surfaces of the lower core box. According to the mould, the structure is simple and reasonable, each core box is made of a cast iron material, the shape of the periphery of the core box is designed to be matched with the sand core, and the total weight of the mould can be reduced and the manufacturing cost can be saved while the strength of the core box is guaranteed and the deformation is prevented; the local part of the core box adopts a loose piece structure, so that the problem that the sand core cannot be smoothly demoulded is effectively solved, the operation is convenient and flexible, and the core-making efficiency is high; moreover, the made sand core is small in deformation and good in sizing precision.

Owner:GUANGXI YUCHAI MASCH CO LTD

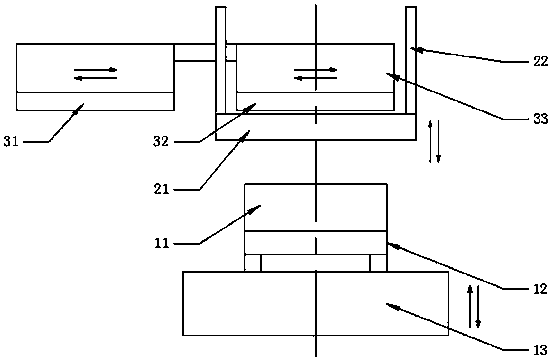

Cold core or inorganic core manufacturing method and cold core or inorganic core manufacturing machine

The invention discloses a cold core or inorganic core manufacturing method and a cold core or inorganic core manufacturing machine. In the cold core or inorganic core manufacturing method, the initial position and the stop position of an upper core box is are the middle position below a core ejection rod of an air blowing / core ejection mechanism; one scheme is as follows: with a lifting type machine, a lower moving trolley drives a lower core box to a lower mold opening position, an upper moving trolley synchronously drives a sand ejection mechanism to a sand ejection position and drives the air blowing / core ejection mechanism to an air blowing / core ejection transit position; when the air blowing / core ejection mechanism ejects a core, a lifting work platform synchronously drives the lower core box to move downwards to the lower mold opening position, and a lifting mechanism delays to synchronously drive the upper core box to move downwards to the middle position; in a cold core or inorganic core manufacturing machine, a middle position space and a mold opening position are formed from top to bottom between the lower end of the core ejection rod of the air blowing / core ejection mechanism and the upper end surface of the lower core box, so that the idle loop time is saved, the equipment waste is reduced and the core manufacturing efficiency is improved.

Owner:SUZHOU MINGZHI TECH

Manual core box core ejecting mechanism and core making method

The invention discloses a manual core box core ejecting mechanism and a core making method. The manual core box core ejecting mechanism comprises a sand reducing block, a core box cavity movable block component, a bottom mold, a core box wood frame component, a nut, a bolt, a core ejecting fixed distance block, a lifting lug, a core box substrate, a sand reducing block positioning block and a core ejecting rod. The manual core box core ejecting mechanism is characterized in that the sand reducing block positioning block is arranged on the core box wood frame component for positioning the sand reducing block mounted on the core box wood frame component. The core ejecting fixed distance block is arranged between the core box substrate and the core ejecting block; and when the core ejecting fixed distance block is removed, the core box substrate and the bottom mold drop on the core ejecting plate under the effect of self gravity or external force, and a sand core is deviated from the bottom mold. The manual core box core ejecting mechanism has the advantages of simple structure, convenience for use, low labor intensity, high core making efficiency, good core making quality and low mold cost, can be applied to various types of manual core box molds, and can realize the functions of core ejection and mold drawing without needing an additional core shooting machine.

Owner:GUANGXI YUCHAI MASCH CO LTD

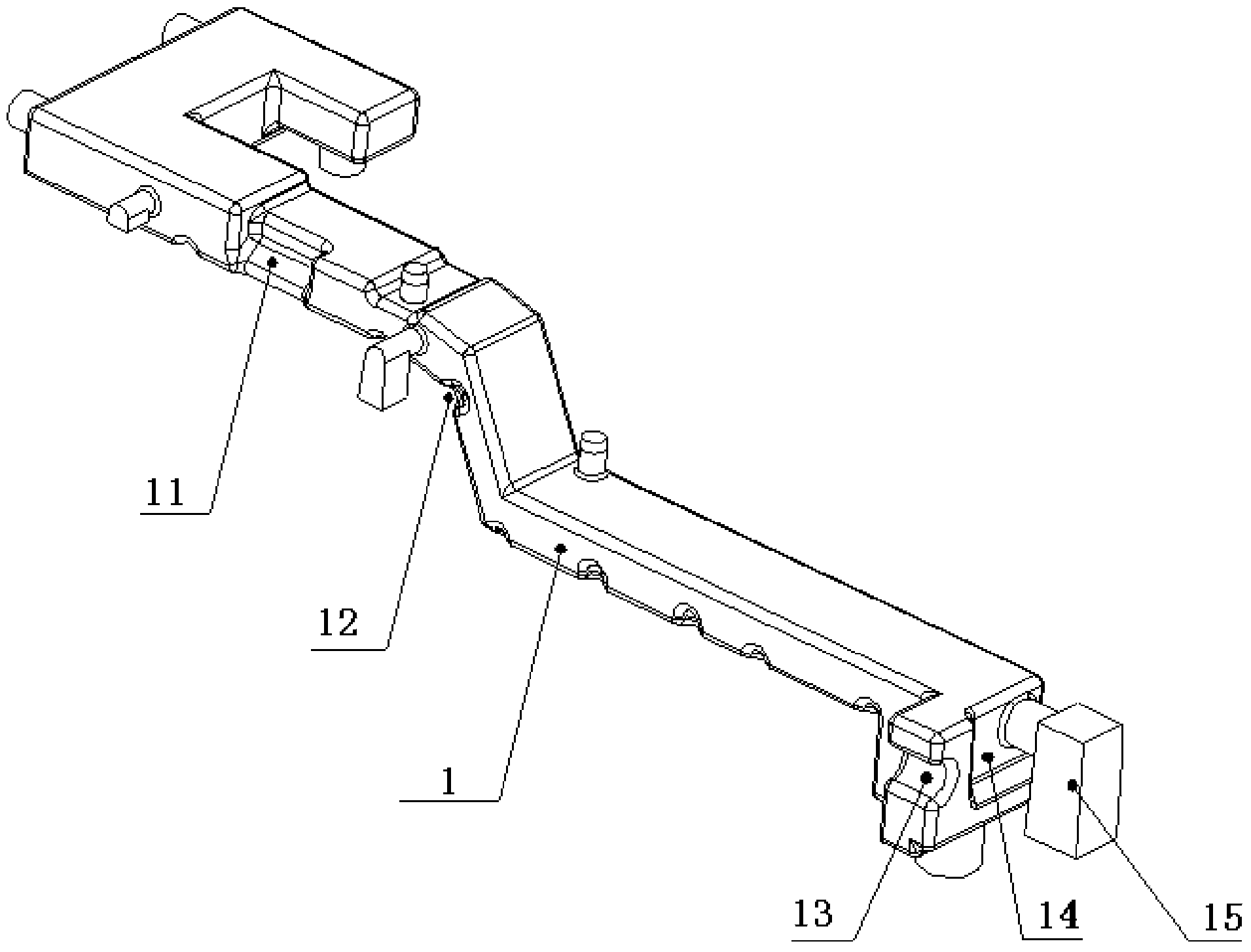

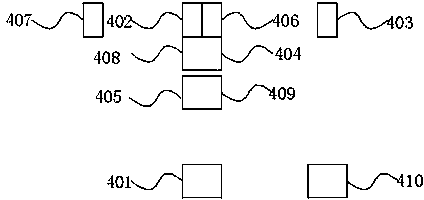

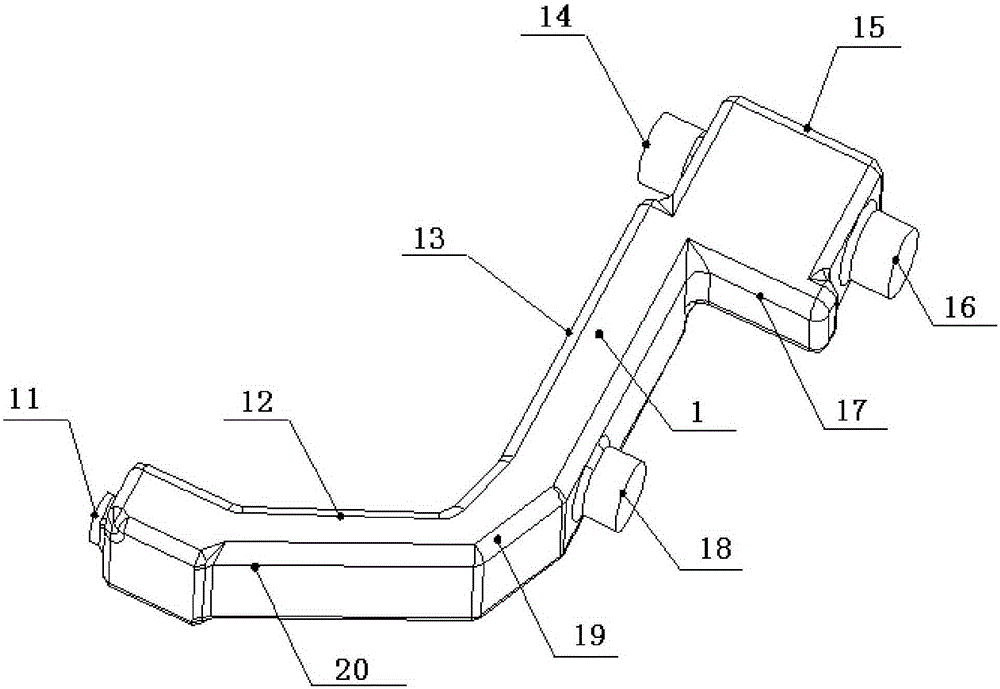

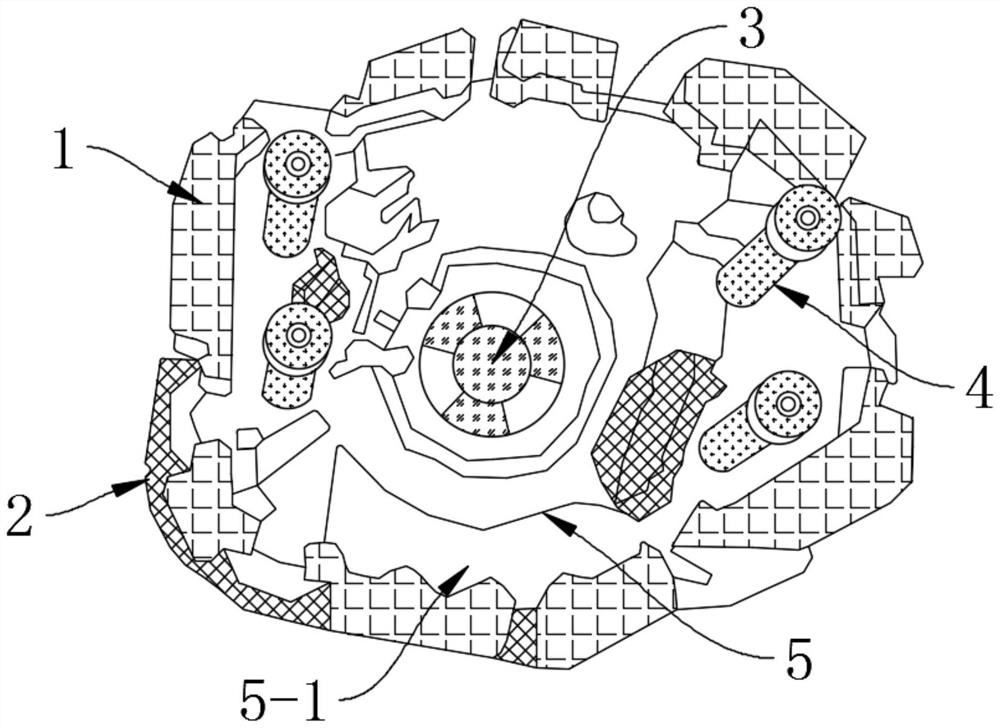

Robot type casting core with long rocker

InactiveCN102601311AImprove core making efficiencyReduce labor intensityFoundry mouldsFoundry coresManufacturing efficiencyRobot

A robot type casting core with a long rocker comprises a third core. A first core and a second core are respectively engaged on two sides of the third core, a fifth core, a sixth core and a fourth core engaged mutually are respectively arranged on the first core, the second core and the third core, a second vertical fastening device is arranged between the first core and the fifth core, a first vertical fastening device is arranged between the second core and the sixth core, a transverse fastening device is arranged on the face separating the first core, the second core and the third core on the lower layer from the fifth core, the sixth core and the fourth core on the upper layer, and a first hanging ring and a second hanging ring are respectively arranged at the top ends of the first vertical fastening device and the second vertical fastening device. Due to the fact that the cores are manufactured mechanically by coating sand and are assembled by unique manners, manufacturing efficiency of the robot type casting core with the long rocker is increased while labor intensity is reduced.

Owner:YICHANG AOLI FOUNDRY

Ultra-large type manual core box mold of v-type engine cylinder body and core making method

PendingCN110465624AHigh precisionAvoid deformationFoundry mouldsFoundry coresMaterials scienceCasting

The invention discloses an ultra-large type manual core box mold of a v-type engine cylinder body, belongs to the technical field of sand mold casting, and solves the problem that an existing manual core box mold is not easy to demold. The core box mold comprises a bottom mold and a side mold assembly, wherein the side mold assembly comprises a first side mold, a second side mold, a third side mold and a fourth side mold which are split, the second side mold is arranged on one side of the bottom mold, the fourth side mold is arranged on the other side of the bottom mold, the first side mold and the third side mold are clamped between the two sides of the second side mold and the fourth side mold correspondingly, a pattern area is arranged in an area surrounded by the first side mold, the second side mold, the third side mold and the fourth side mold, and a plurality of split-type patterns are arranged in the pattern area. According to the core box mold, the sand core quality and precision can be effectively improved. The invention further discloses a core making method. The method is used for core making, so that the on-site operation convenience can be ensured.

Owner:GUANGXI YUCHAI MASCH CO LTD

Molding sand for wet core during malleable iron pipe fitting casting

InactiveCN110479951AImprove wet compressive strengthImprove breathabilityFoundry mouldsFoundry coresPipe fittingReusability

The invention relates to the technical field of casting, in particular to molding sand suitable for a wet core during malleable iron pipe fitting casting. The molding sand is prepared from the following components of, in percentage by mass, 45%-55% of old sand, 35%-45% of fresh sand, 5%-8% of bentonite, 0.1%-0.4% of starch, 0.1%-0.4% of coal powder and 1%-3% of water. The fresh sand and the old sand are sequentially added into a sand mixer according to a ratio, then the coal powder and the bentonite are added, then the starch is added, finally the water is added, stirring is carried out in thesame direction, and after all the components are uniformly stirred, the molding sand is obtained. The molding sand can be used for core producing for the wet core, and the prepared wet core is high in reusability and strong in binding force. The wet core prepared by the molding sand is high in wet pressure strength, and good in collapsibility and good in air permeability after casting. The use ofthe core iron is cancelled, the waste of the core iron material is avoided, a sorting core iron working procedure is not needed, and the core making efficiency is further improved.

Owner:赤峰市建支管业有限公司

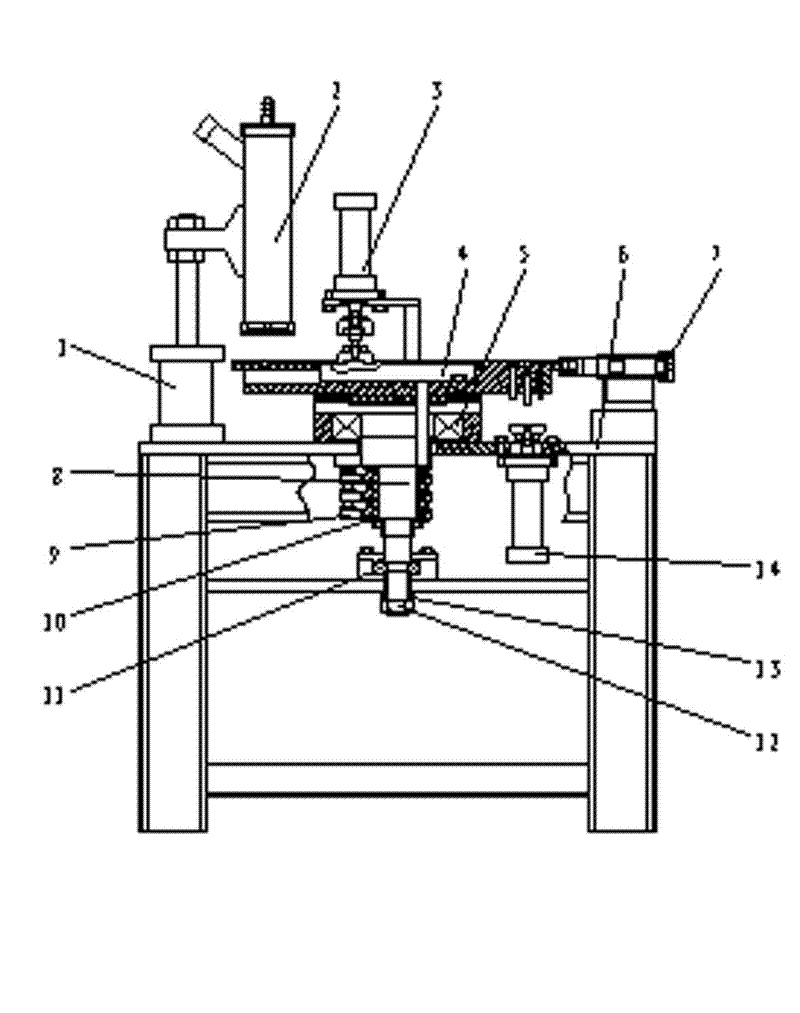

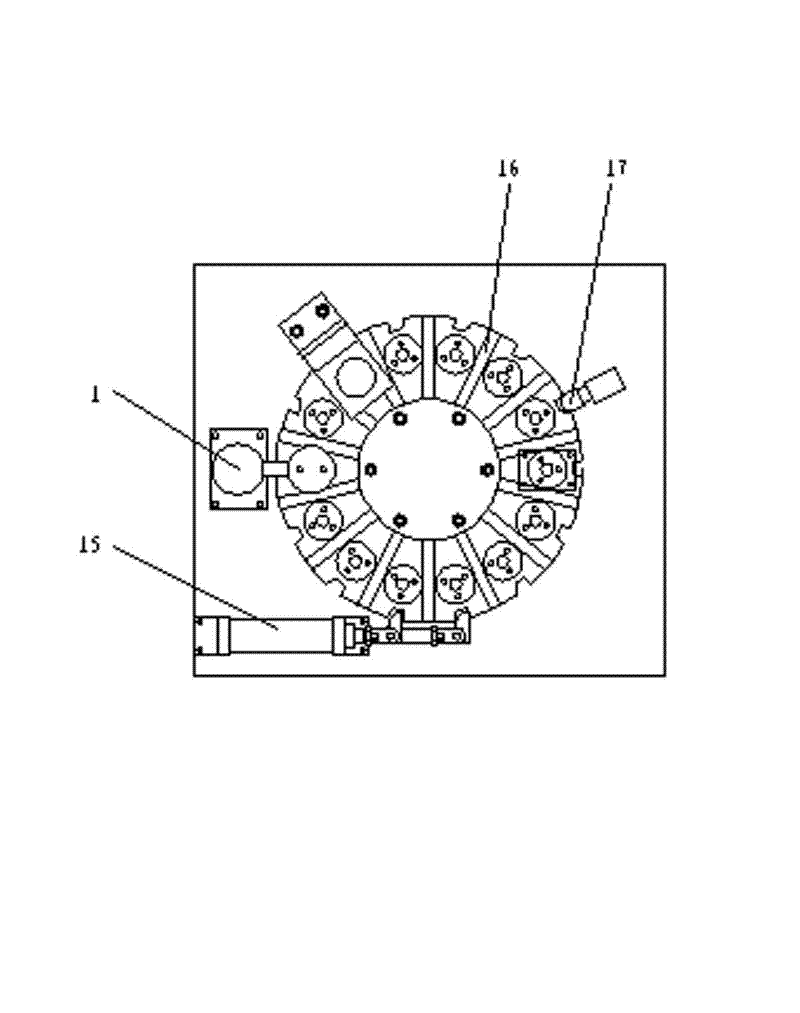

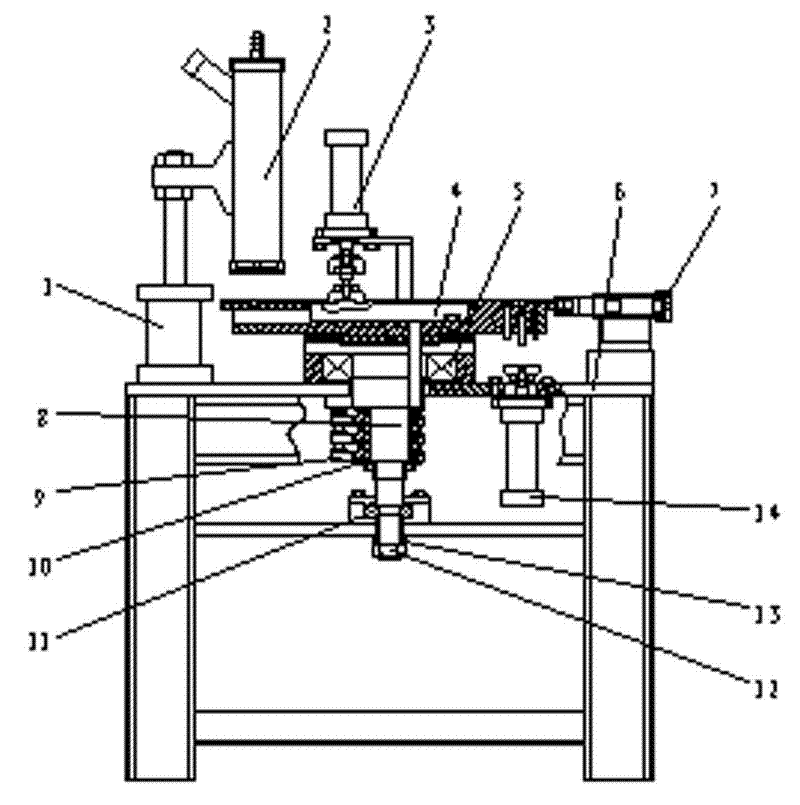

Manufacturing device of knock-off core and manufacturing method thereof

InactiveCN102019355BQuality assuranceReduce labor intensityFoundry mouldsMoulding machinesElectric consumptionMechanical engineering

The invention relates to a manufacturing device of a knock-off core and a manufacturing method thereof. One side above a stand is provided with a sand ejecting cylinder, the sand ejecting cylinder is connected with a sand ejecting tube, the middle part above the stand is provided with a resetting cylinder controlled by a 14-station rotating mould, a rotating shaft is arranged below the resetting cylinder, the other side above the rack is provided with a positioning cylinder, a working platform is arranged below the positioning cylinder, and the front end part above the stand is provided with a pusher-type cylinder. By adopting the special 14-station knock-off core manufacturing device which has simple operation, low manufacturing cost and stable operation and can realize continuous automatic production in the invention, the production requirements can be met, the core production efficiency is improved, the production speed of the knock-off core is improved to one piece per six secondsfrom one piece per two minutes, the working efficiency is improved by nearly 20 times, the electricity consumption is saved by 1 / 3, the quality of the knock-off core is ensured, and the labour intensity of workers is reduced.

Owner:广东省韶铸集团有限公司

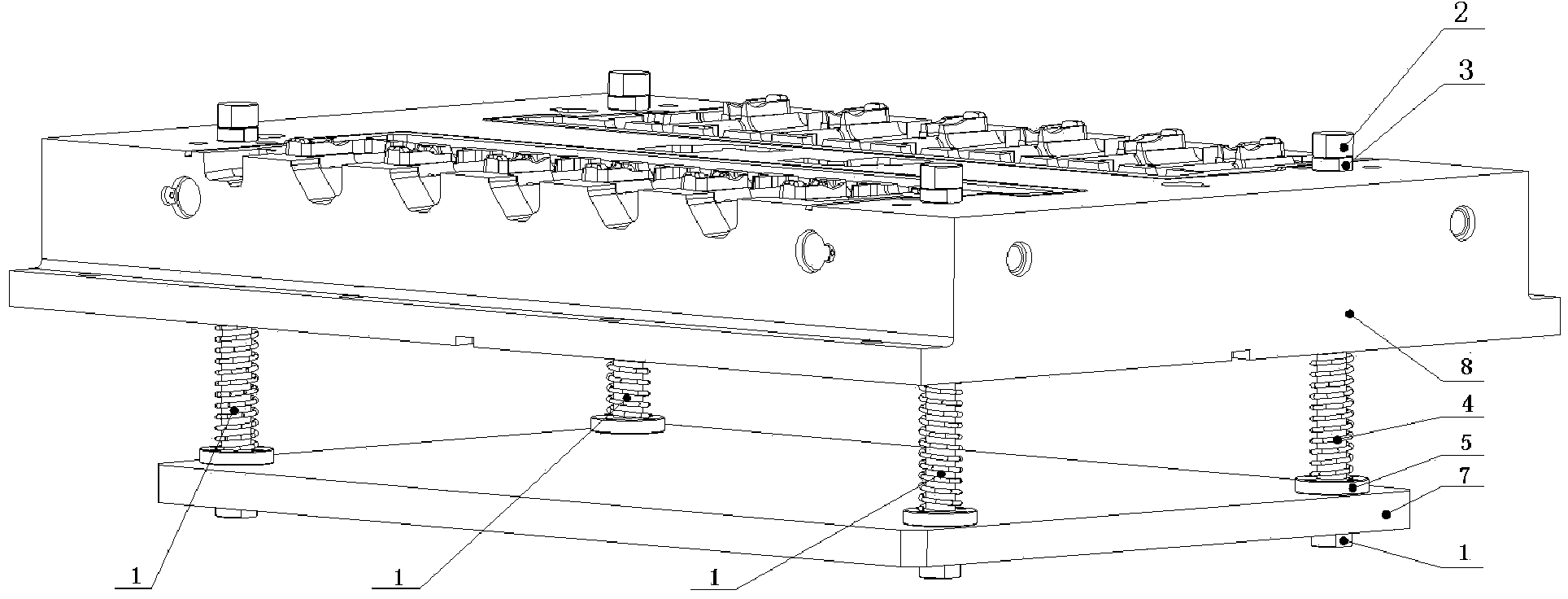

Lifting and returning device of lower ejecting core plate

InactiveCN103862002ASimple structureGuaranteed uptimeMoulding machinesEngineeringManufacturing quality

The invention discloses a lifting and returning device of a lower ejecting core plate. The lifting and returning device comprises lifting rods, lifting rod locking nuts and returning springs, wherein each lifting rod comprises a bolt head and a screw rod and can penetrate through the lower ejecting core plate in a sliding manner, the bolt head stops at the bottom surface of the lower ejecting core plate, and the screw rod is fixedly arranged in a lower core box in a penetrating manner; the lifting rod locking nut is adaptively screwed with one end of the screw rod, extending out of the lower core box; the returning spring is arranged on the screw rod of the lifting rod in a penetrating manner; the upper end of the returning spring is butted with the bottom surface of the lower core box and the lower end of the returning spring is butted with the top surface of the lower ejecting core plate. The lifting and returning device disclosed by the invention has the advantages that the structure is simple and reasonable; the returning device is arranged between the lower core box and the lower ejecting core plate, and the lower ejecting core plate can be automatically returned in time, so that the operation of a core box mold is stable, the core manufacturing efficiency is high, the core manufacturing quality is good and the service life of the mold is long.

Owner:GUANGXI YUCHAI MASCH CO LTD

Novel structure for enhancing conduction efficiency of casting hot core box

InactiveCN110340287AQuality improvementIncrease local temperatureFoundry moulding apparatusEngineeringCopper

The invention relates to a novel structure for enhancing conduction efficiency of a casting hot core box. The structure comprises an upper core box body, upper core box cup mounting grooves, upper core box cups and copper bar fixing holes, wherein the six upper core box cup mounting grooves are formed in the upper side of the upper core box body, and the six upper core box cups are embedded fixedly in the inner sides of the upper core box cup mounting grooves respectively. According to the novel structure for enhancing the conduction efficiency of the casting hot core box, the eccentric copperbar fixing hole is formed in the arranged upper core box cup, a heat conduction copper bar is inlaid in the copper bar fixing hole, the heat conduction copper bar needs to be tightly matched in the copper bar fixing hole, a large copper bar is inlaid in the copper bar fixing hole in the upper core box cup of a solid mold steel structure, so that the heat conduction efficiency is improved, the local temperature of the mold is effectively improved, the process requirements are met, and the production efficiency is improved.

Owner:十堰天凯模具制造有限公司

Positioning and taking-out device for movable types in die cavity

InactiveCN107052241AFlexible replacementReduce red tapeMoulding toolsFoundry mouldsMovable typeMagnet

The invention relates to a positioning and taking-out device for movable types in a die cavity. The positioning and taking-out device comprises a die, the movable types, positioning grooves, positioning magnets and a strong magnetism handle. The positioning groove is formed in the die cavity. The positioning magnets are arranged at the bottoms of the movable types, the movable types are arranged in the positioning grooves, and the strong magnetism handle is used for taking the movable types arranged in the positioning grooves out. According to the provided positioning and taking-out device for the movable types in the die cavity, the ordinary magnets are used for positioning the movable types, it can be guaranteed that the movable types are not brought out by a sand core in the normal core manufacturing process, the complex procedures that when core manufacturing and drawing are conducted every time, the movable types are brought out, and installation needs to be conducted again are reduced, the powerful magnets are used for taking out the movable types, flexible replacement of the movable types in the die cavity is achieved, field operation is convenient, and the core manufacturing efficiency is improved.

Owner:NINGXIA KOCEL MOLD

Silicate inorganic binder for casting and method for preparing silicate inorganic binder for casting

The invention relates to a silicate inorganic binder for casting and a method for preparing the silicate inorganic binder for casting. The silicate inorganic binder for casting consists of crystalline water-contained sodium metasilicate, boric acid, sodium tripolyhosphate and an organic modifier. The silicate inorganic binder for casting is high in binding property, long in storage time, nontoxic and harmless and low in cost; the inorganic binder prepared by the method is high in wettability and binding property; and the molding sand made by the silicate inorganic binder is high in flowability, low in gas forming property, long in storage time and high in applicability, and the old sand can be recycled.

Owner:CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Ventilation cooling sand core for casting cylinder jacket of diesel engine and manufacturing method thereof

ActiveCN102430717BReduce sand consumptionPrevent peelingFoundry mouldsFoundry coresCold airDieseling

The invention discloses a ventilation cooling sand core for casting a cylinder jacket of a diesel engine. The ventilation cooling sand core comprises a core shell, a core bar and a ventilation rope, wherein the core bar comprises a sleeved inner steel pipe and a longer outer steel pipe; the upper ends of the inner steel pipe and the outer steel pipe are fixed together with a first ring-shaped steel plate; multiple upper vent holes are arranged at the upper end of the inner steel pipe; the lower end of the inner steel pipe is fixed together with the upper surface of a second ring-shaped steel plate; the inner opening of the second ring-shaped steel plate is downward connected with a hopper-shaped conical steel pipe and provided with multiple lower vent holes; a bottom sealing plate is fixed at the lower end of the outer steel pipe; a cold air cavity is formed among the outer steel pipe, the bottom sealing plate and the hopper-shaped conical steel pipe; the central inner ring of the first ring-shaped steel plate is upward fixedly provided with a first steel pipe; the first steel pipe, the inner steel pipe and the hopper-shaped conical steel pipe form an insertion channel of a cooling ventilation pipe; and the space among the lower vent holes, the inner steel pipe and the outer steel pipe and an upper air outlet form a hot air channel. According to the invention, the core manufacturing efficiency is improved, the qualification rate of the cylinder jacket is increased, the quality of the cylinder jacket is stabilized, and the production cost is lowered.

Owner:HUDONG HEAVY MACHINERY

A kind of production method of cold box resin for casting

The invention relates to a method for producing resin, and particularly relates to a method for producing casting cold-box resin. The method comprises the following steps: adding dissolved industrial phenol to a reaction kettle; starting an agitator; adding solid paraformaldehyde, a regulator and 0.08-0.12% of metal ion catalyst; opening a steam valve, slowly heating up, and heating up to 105 DEG C within 40-50 minutes; keeping constant temperature at 105-108 DEG C for 30 minutes; heating up to 112 DEG C within 10-20 minutes, and keeping constant temperature at 112-115 DEG C for 50 minutes; continuing to heat up and dewatering under normal pressure after heat preservation is finished; timing constant temperature when the temperature inside the kettle ascends to 120 DEG C, and keeping constant temperature at 120-123 DEG C for 30 minutes; after constant temperature is finished, vacuumizing and continuing to dewater; stopping dewatering when the total dewatering amount achieves 60% of formaldehyde amount; adding a polar dibasic acid ester, nonpolar high-boiling point solvent oil and a modifier; agitating for 60 minutes; adding an enhancer when cooling to below 40 DEG C; evenly agitating, detecting and packaging. The casting cold-box resin which is low in viscosity, and high in casting sand strength, can be used for a long period of time, and meets core-making production in batches is provided by the invention.

Owner:共享新材料(山东)有限公司

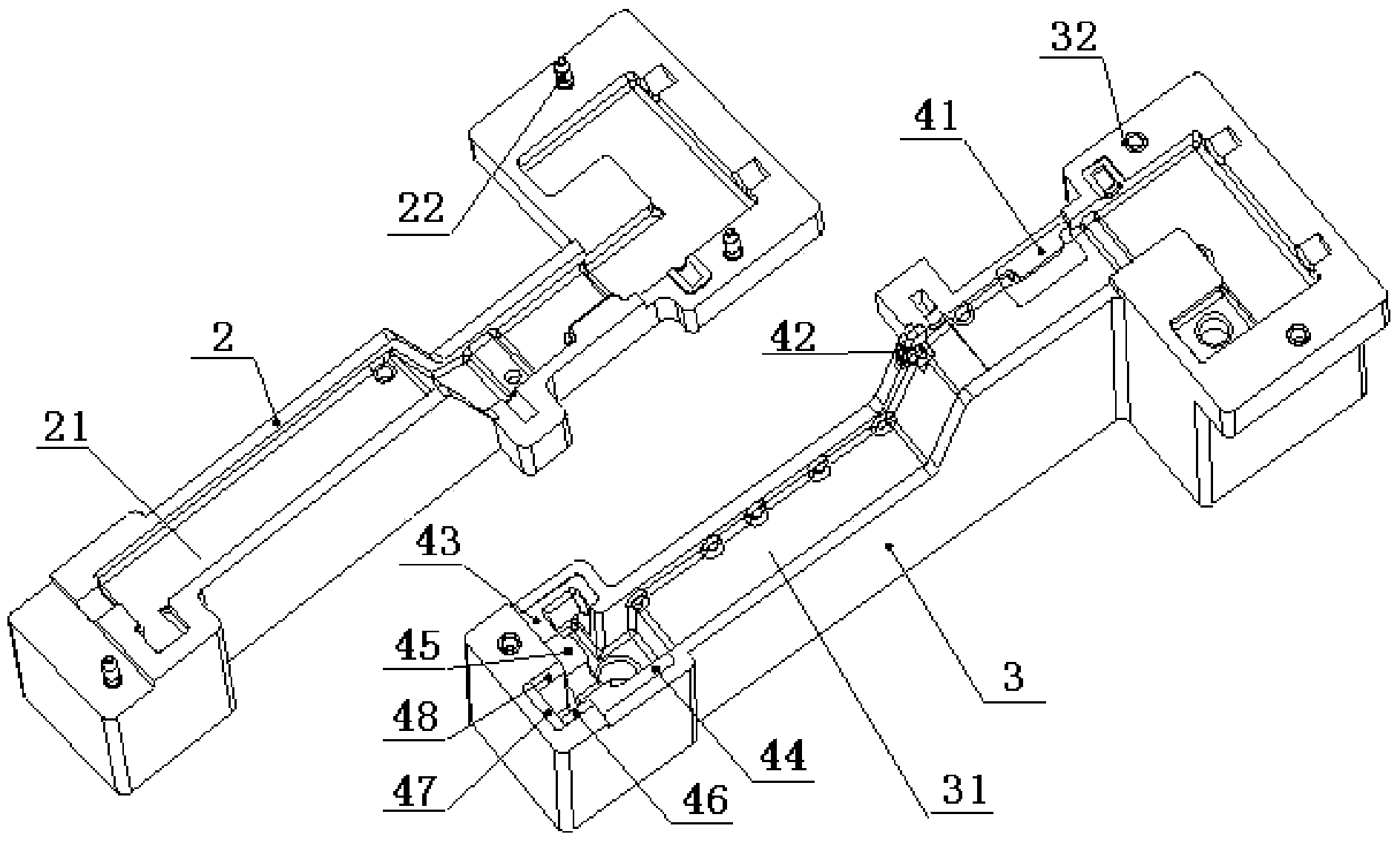

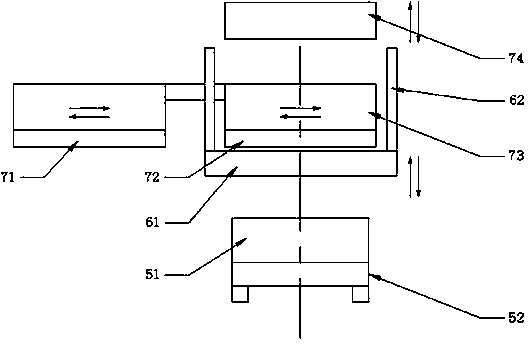

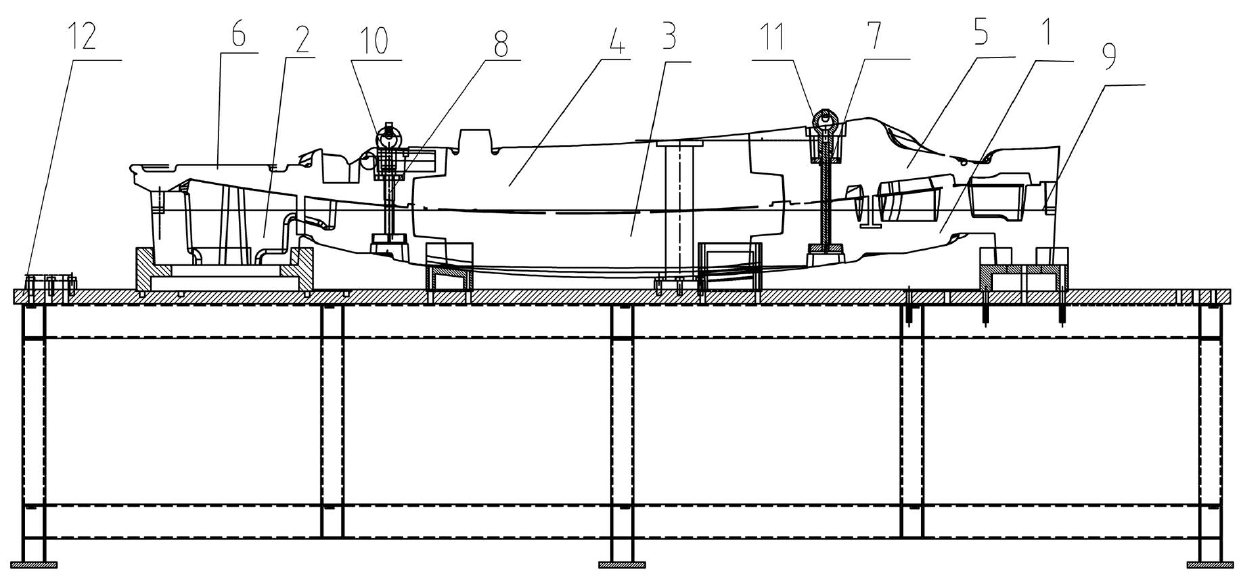

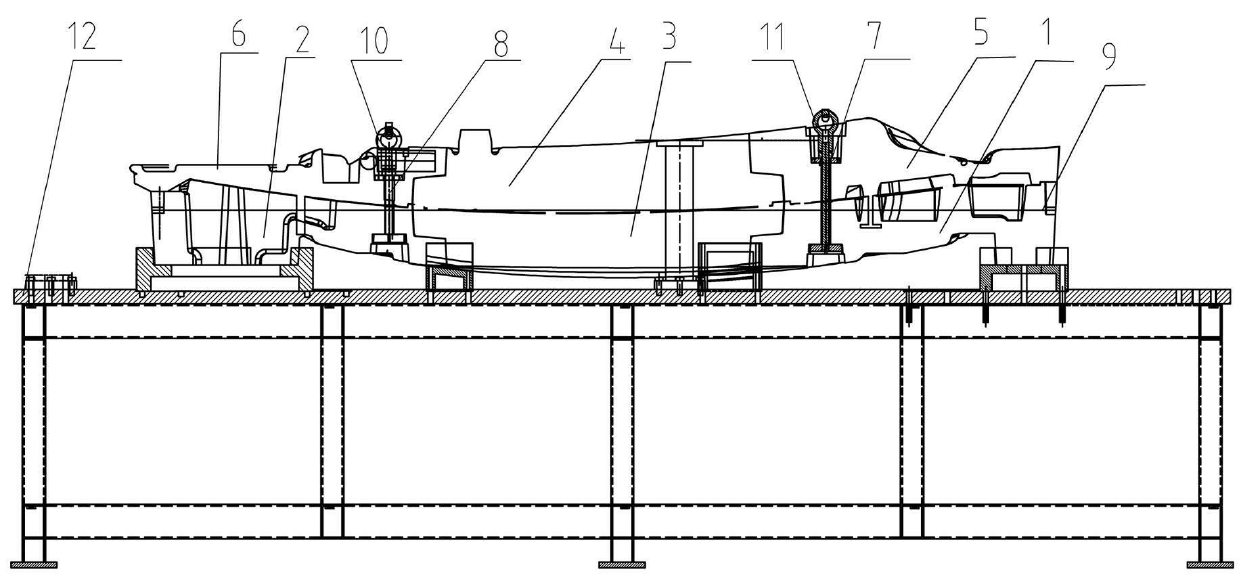

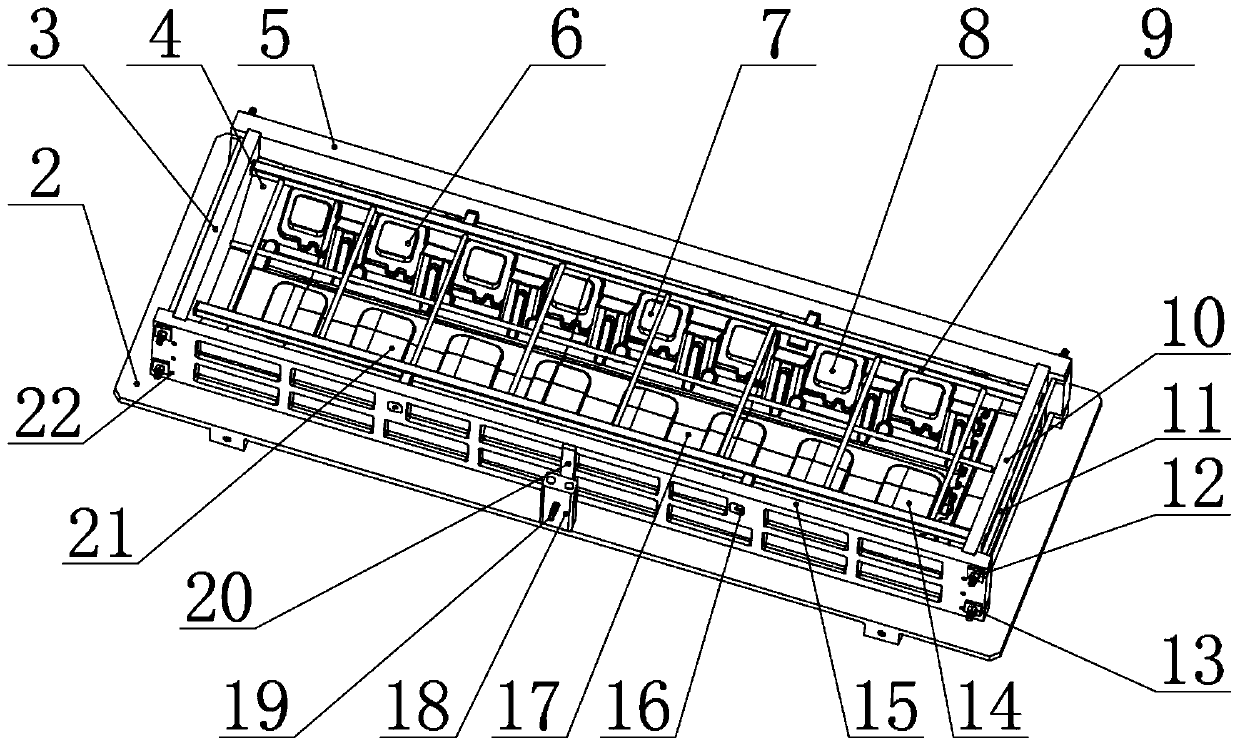

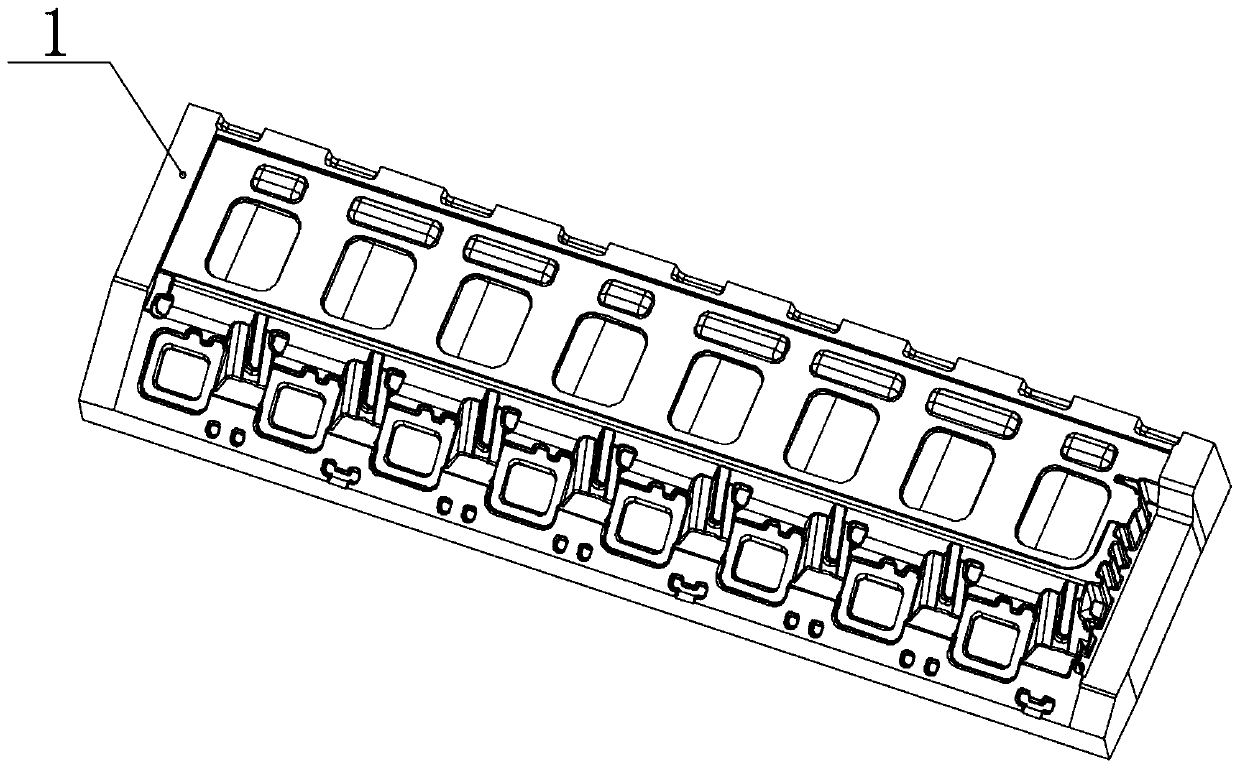

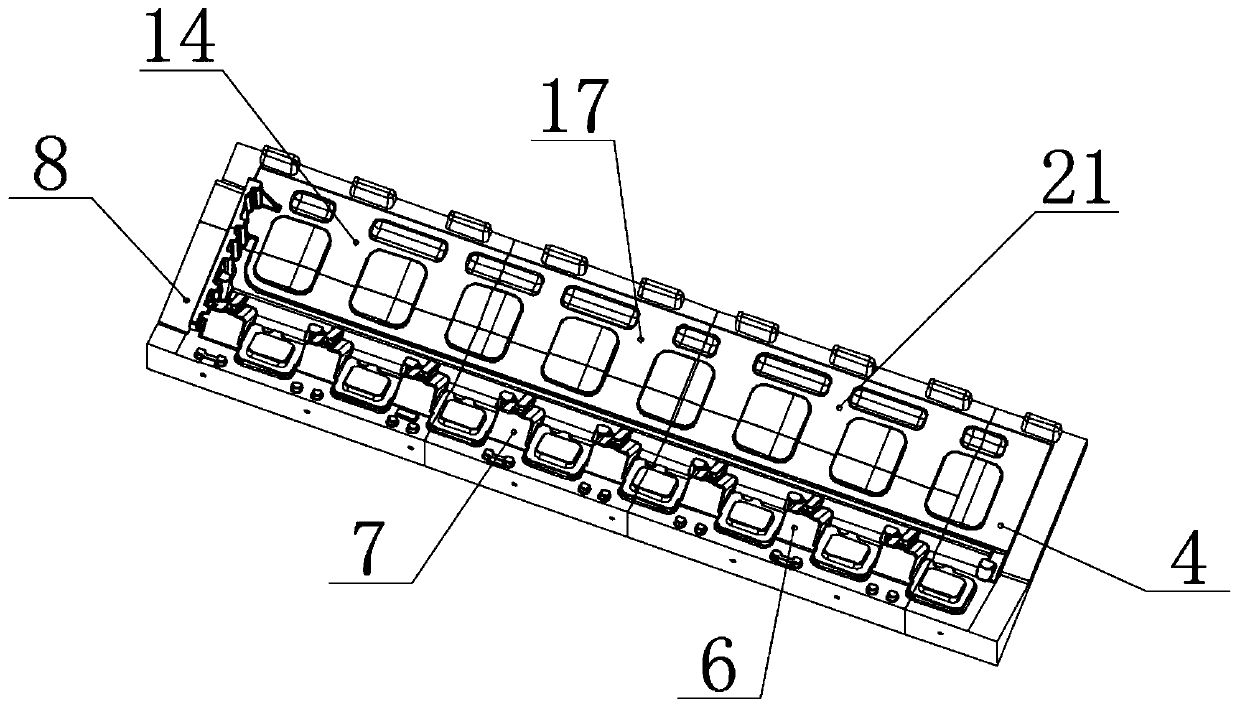

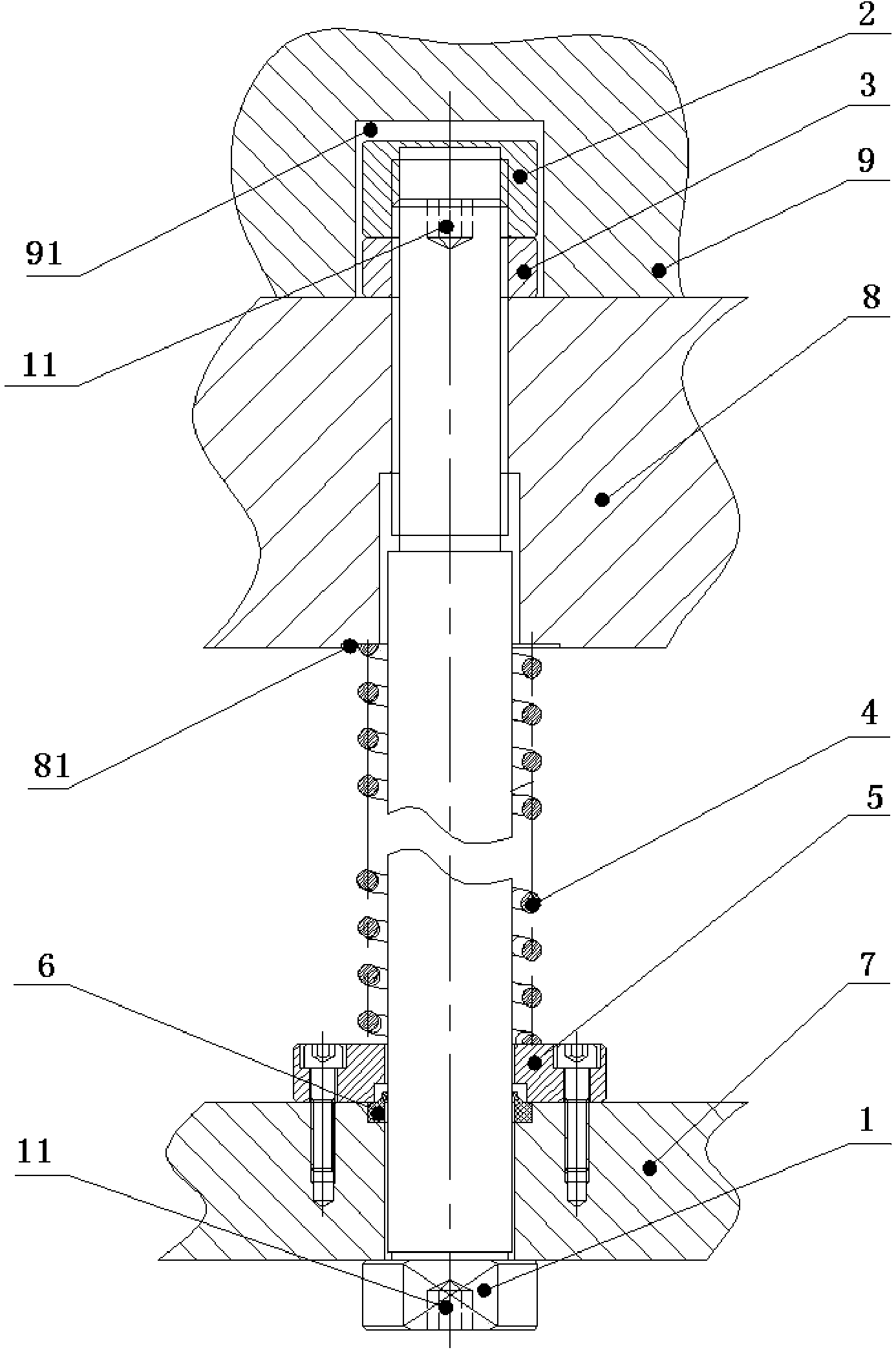

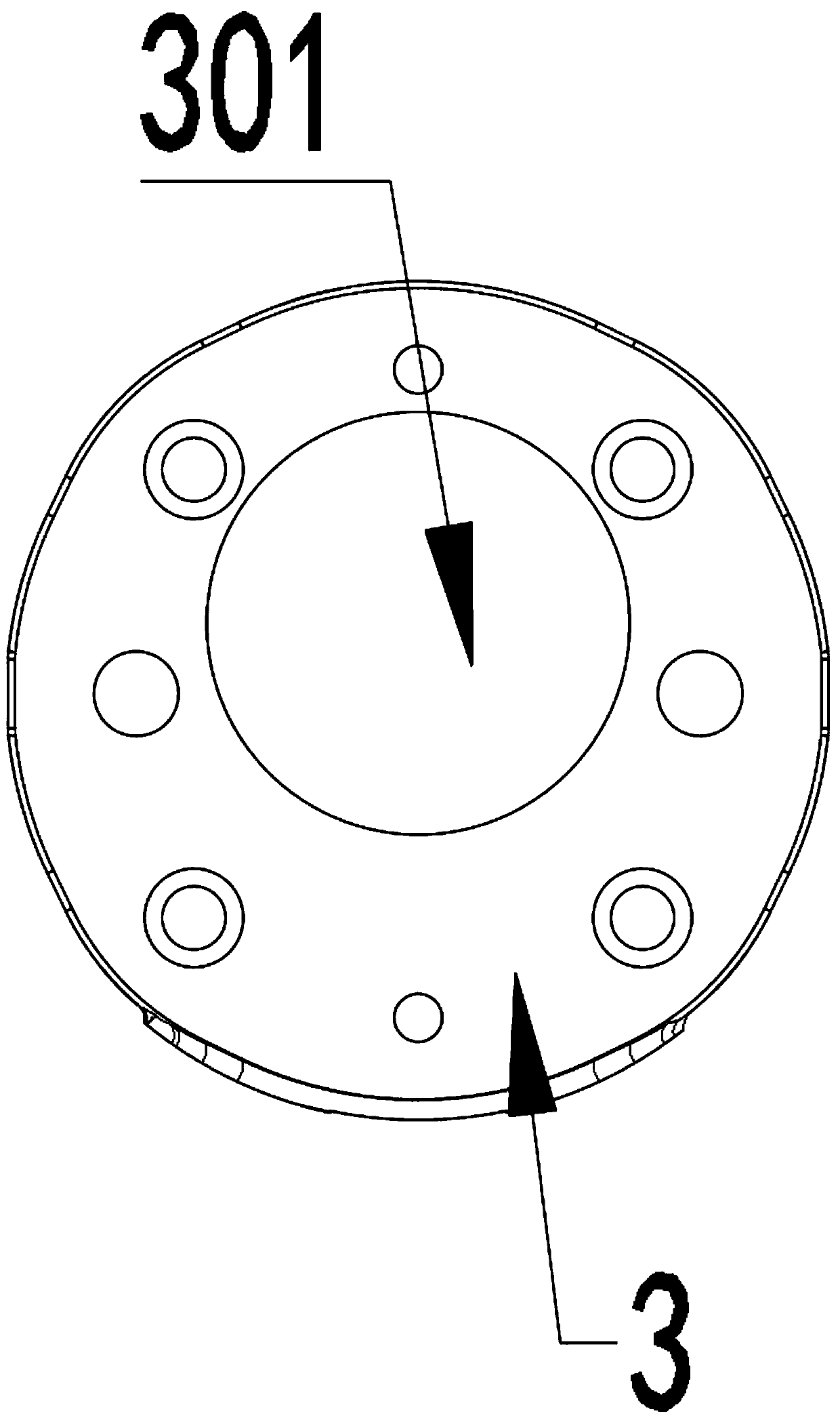

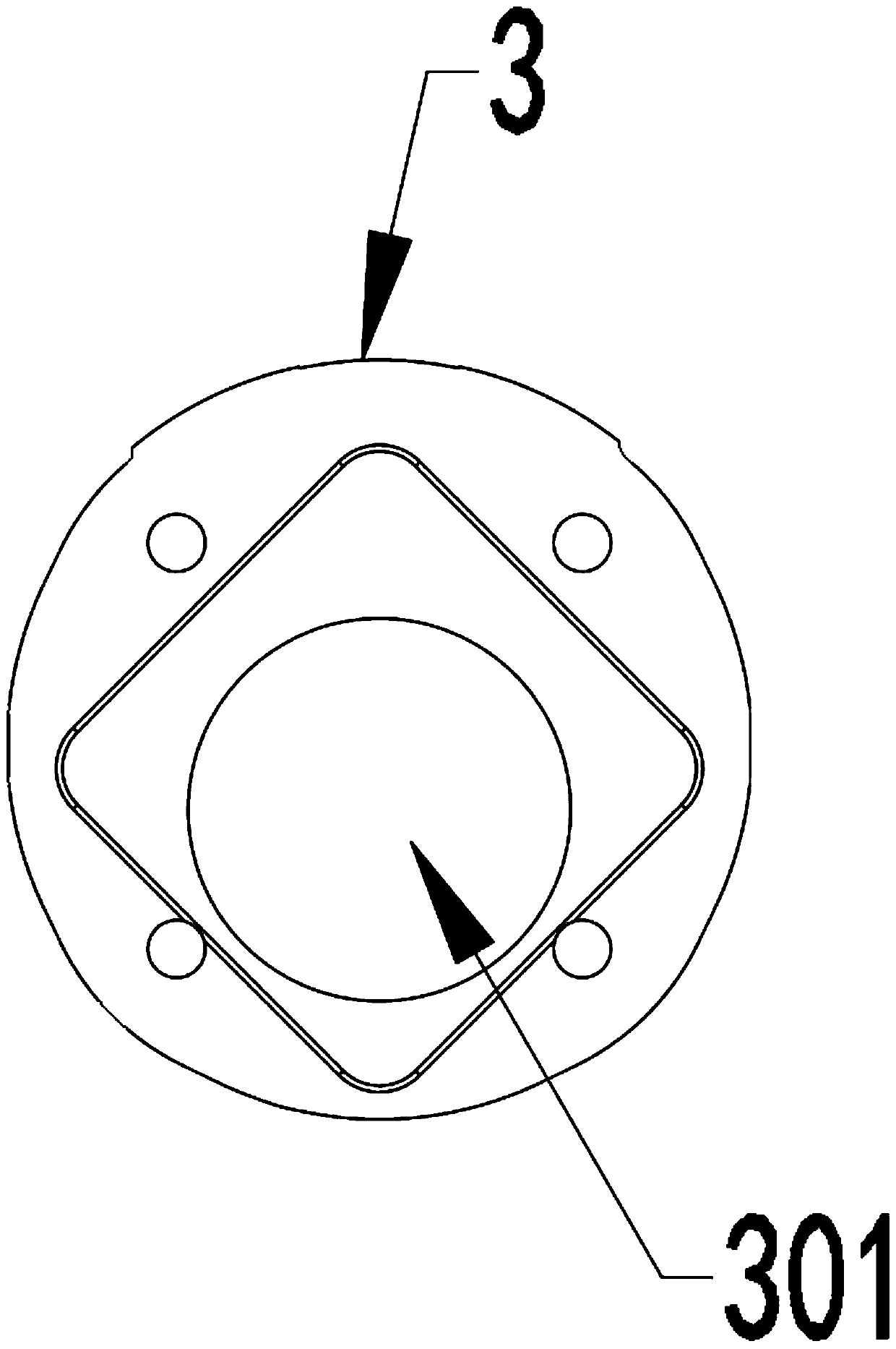

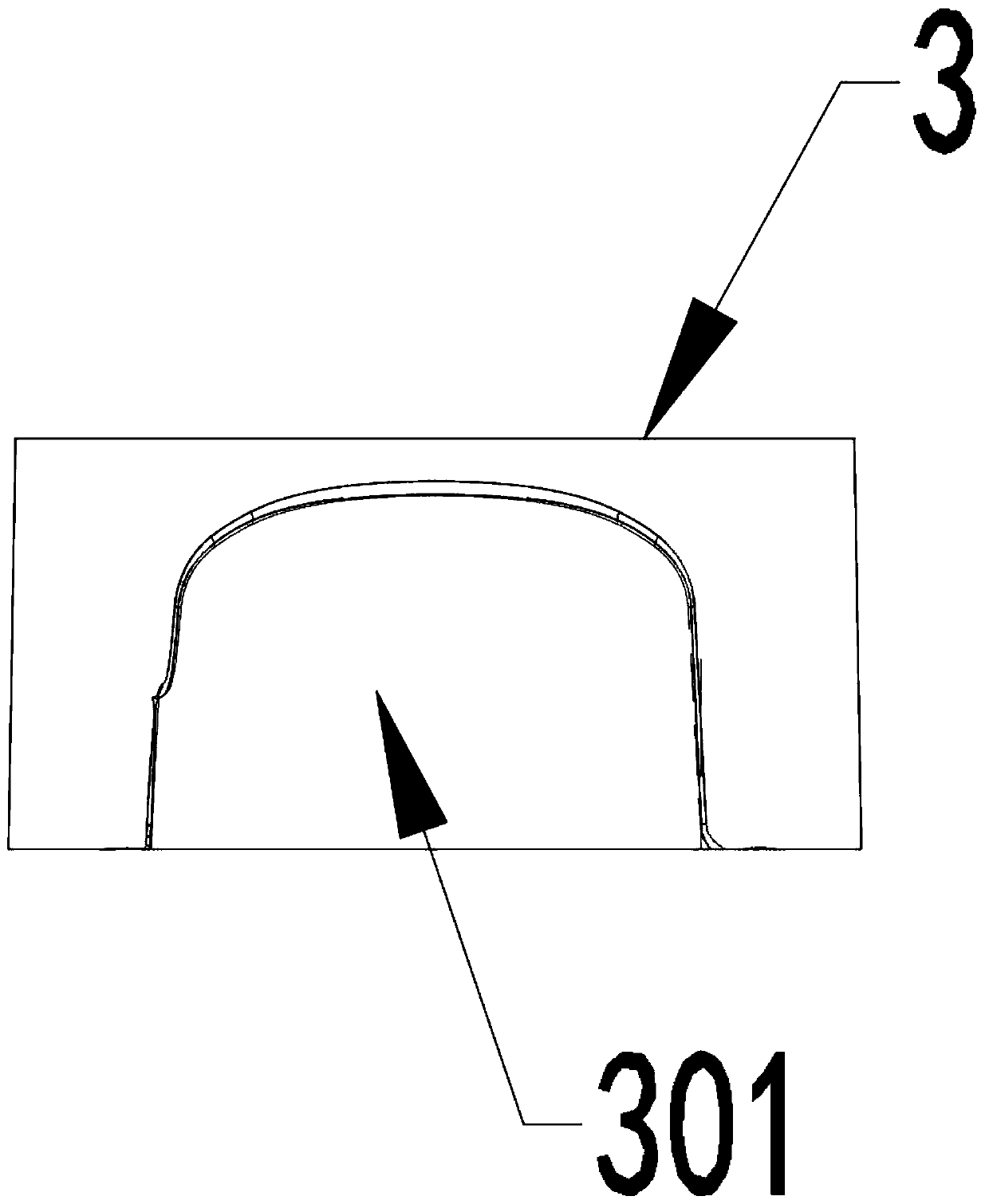

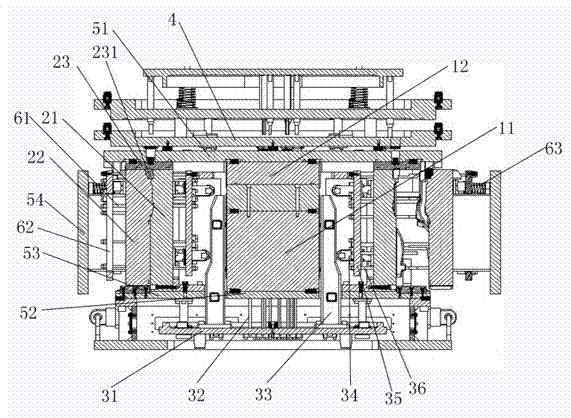

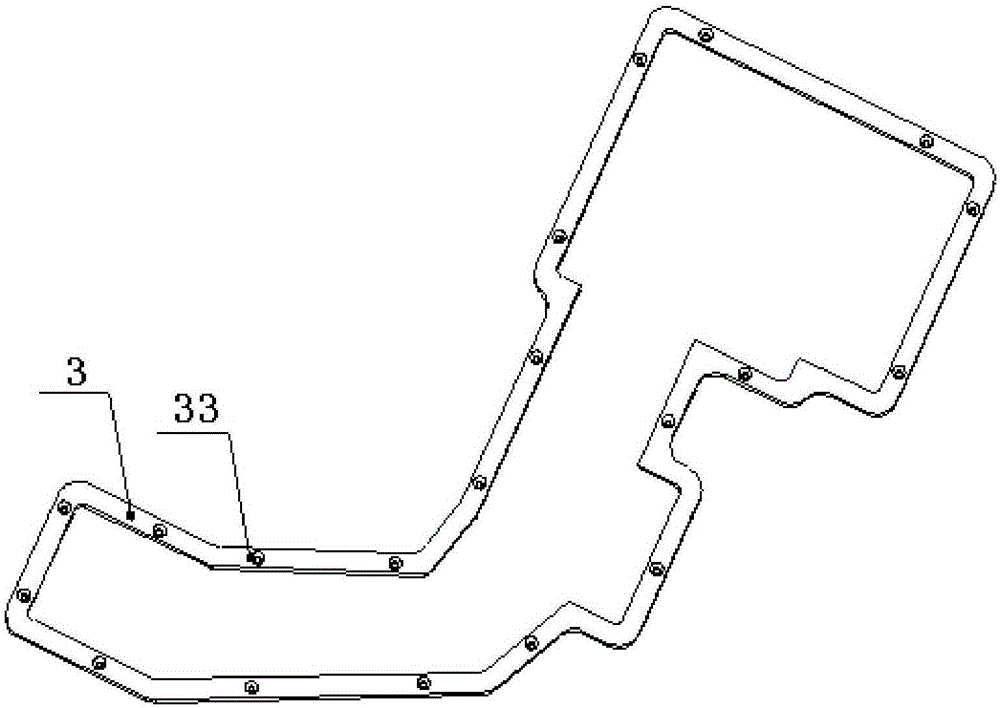

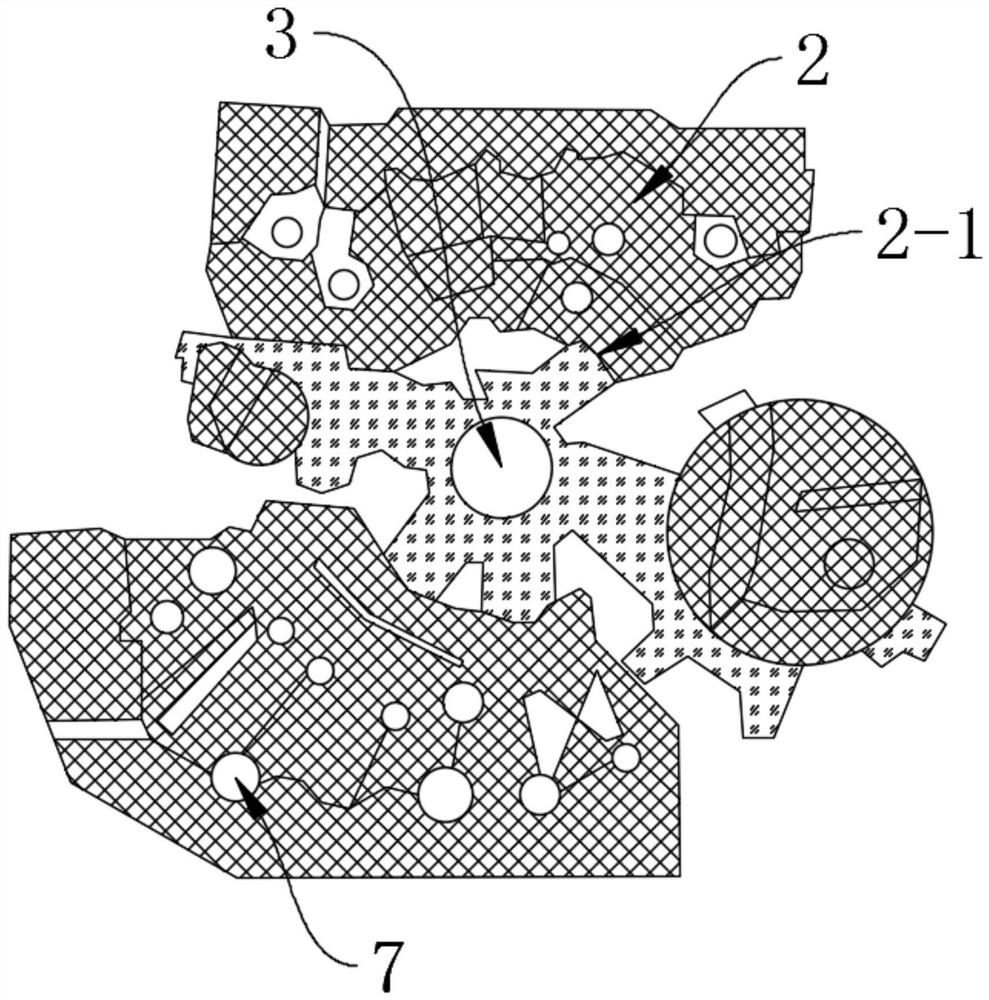

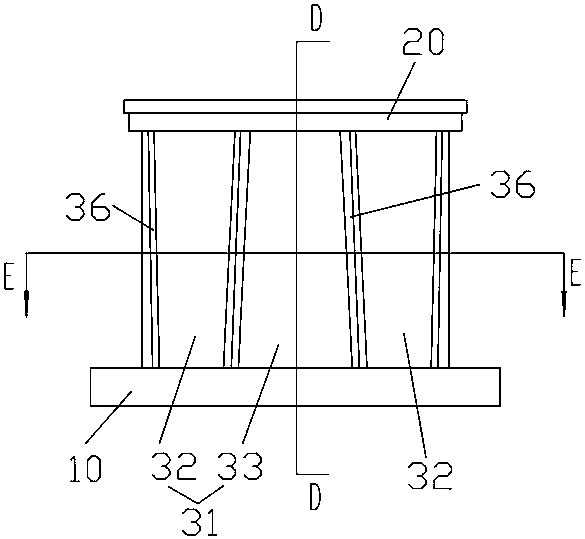

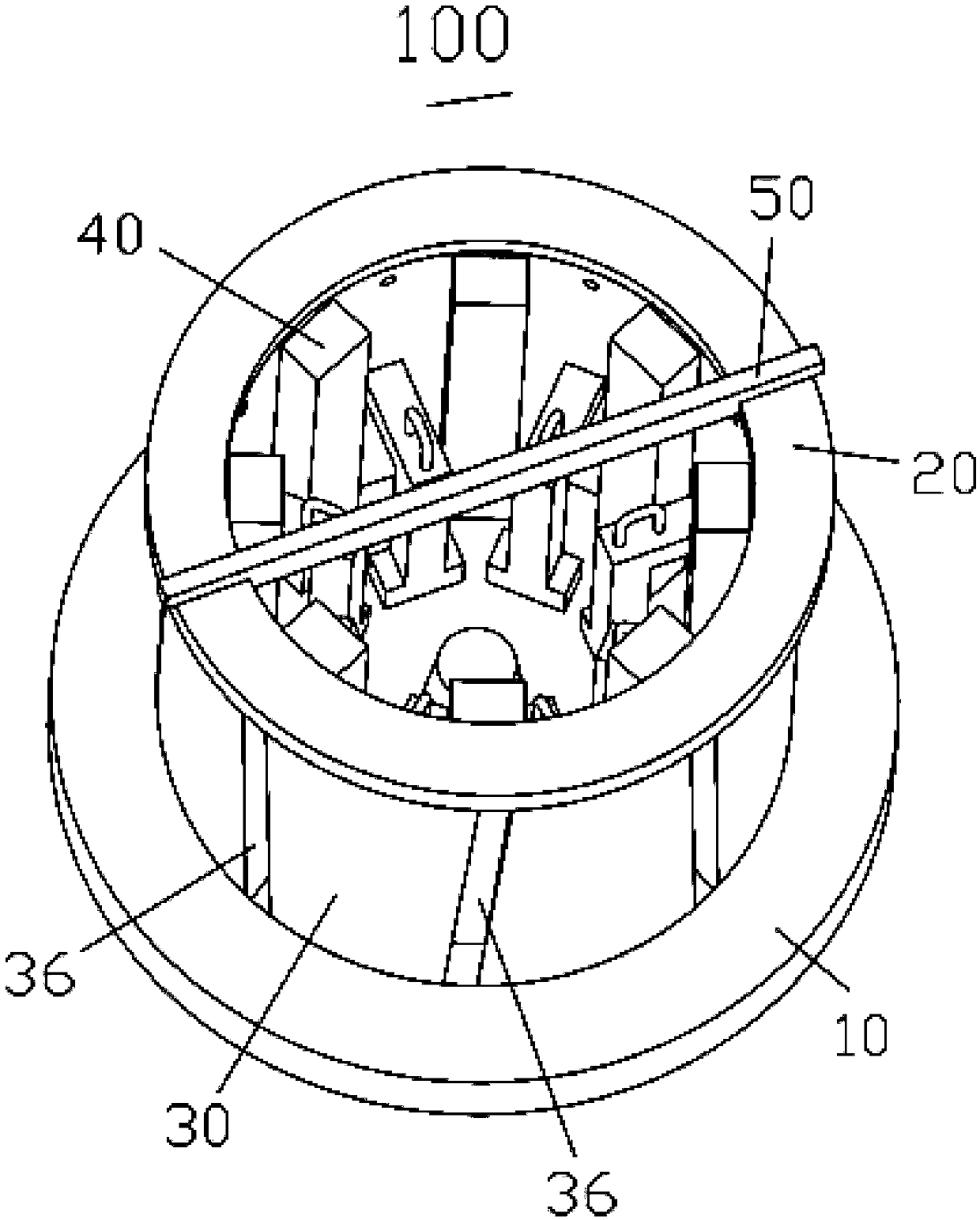

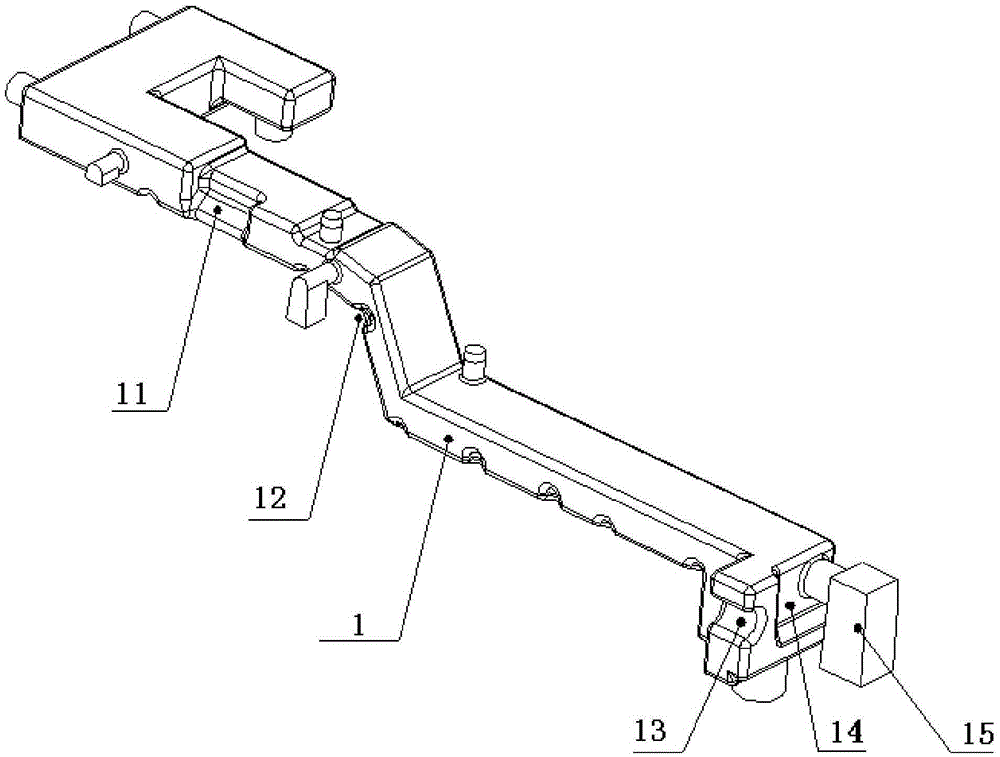

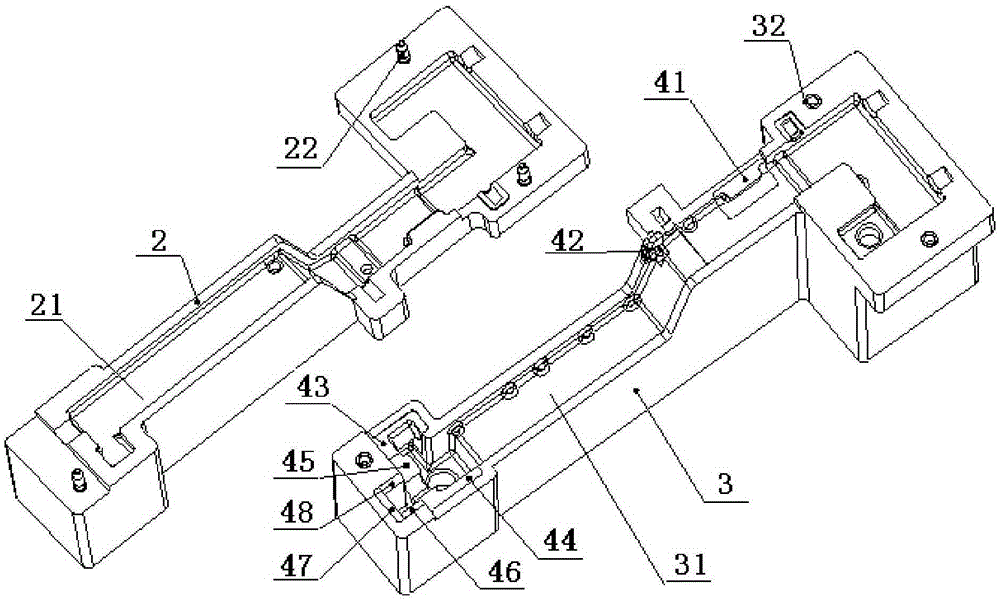

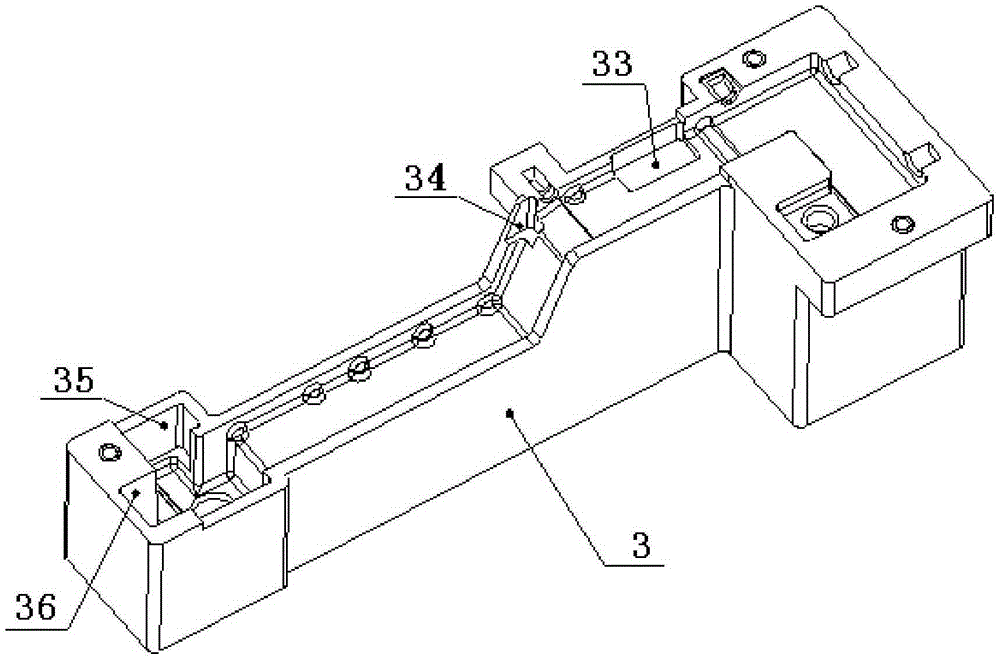

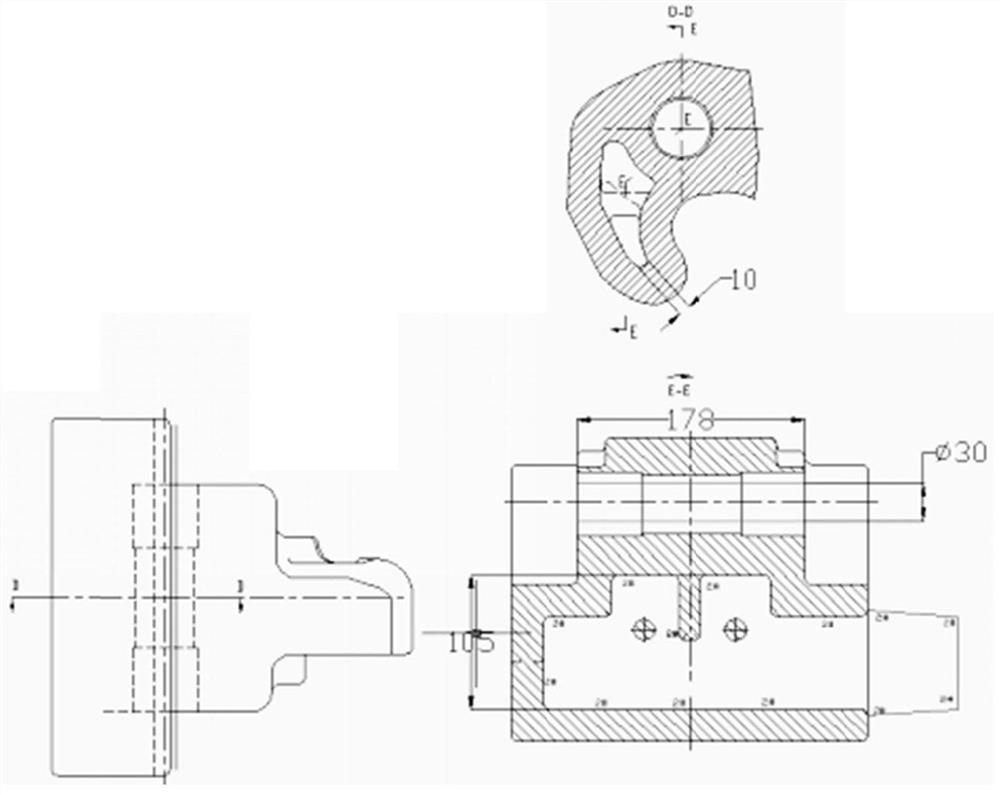

Vertical and horizontal composite core box for simultaneously preparing jacket core and oil duct core

ActiveCN103752768BIncreasing the thicknessImprove firmnessFoundry moulding apparatusEngineeringWater jacket

The invention discloses a vertical and horizontal composite core box for simultaneously preparing a water jacket core and an oil duct core. The vertical and horizontal composite core box comprises a vertical and horizontal composite a jacket core mold, an oil duct core mold, a sand shooting mechanism and a core ejection mechanism, wherein the water jacket core mold comprises a lower core box, an upper core box which is arranged above the lower core box and forms a core box cavity with the lower core box, and a first core ejection hole which is formed in the bottom of the lower core box and communicated with the core box cavity; the oil duct core mold comprises a static mold arranged on the outer side of the lower core box and / or the upper core box, a movable mold which is arranged on the outer side of the static mold and forms a mold cavity with the static mold, and a second core ejection port which is arranged on the inner side of the static mold and is communicated with the mold cavity. The number of the prepared molds is reduced, the cost of the mold, the production time and labor force are saved, and the core preparation efficiency is greatly improved. Moreover, the surface quality of the oil duct core is improved, and the ramming degree of the oil duct core is improved.

Owner:SUZHOU MINGZHI TECH

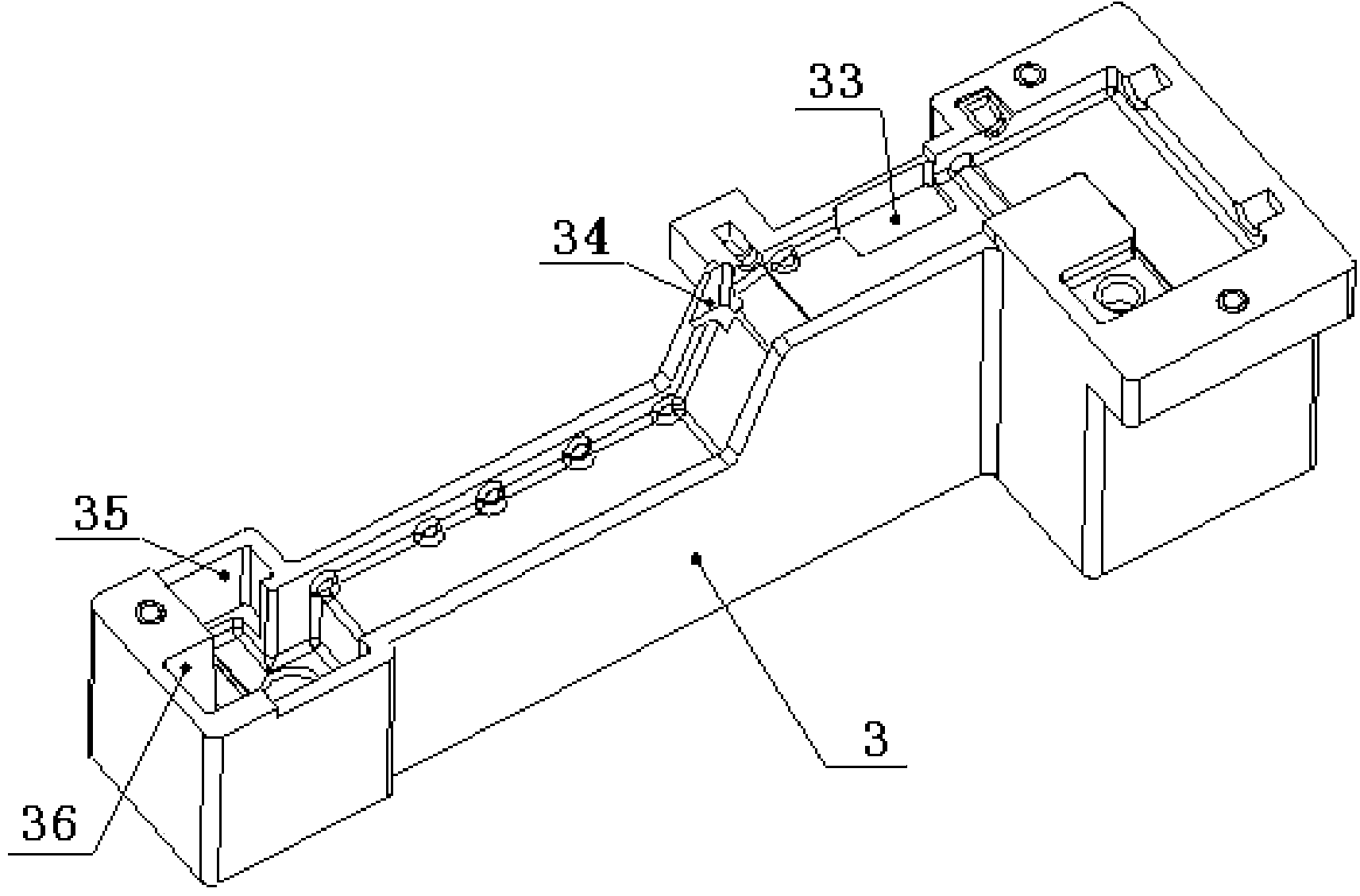

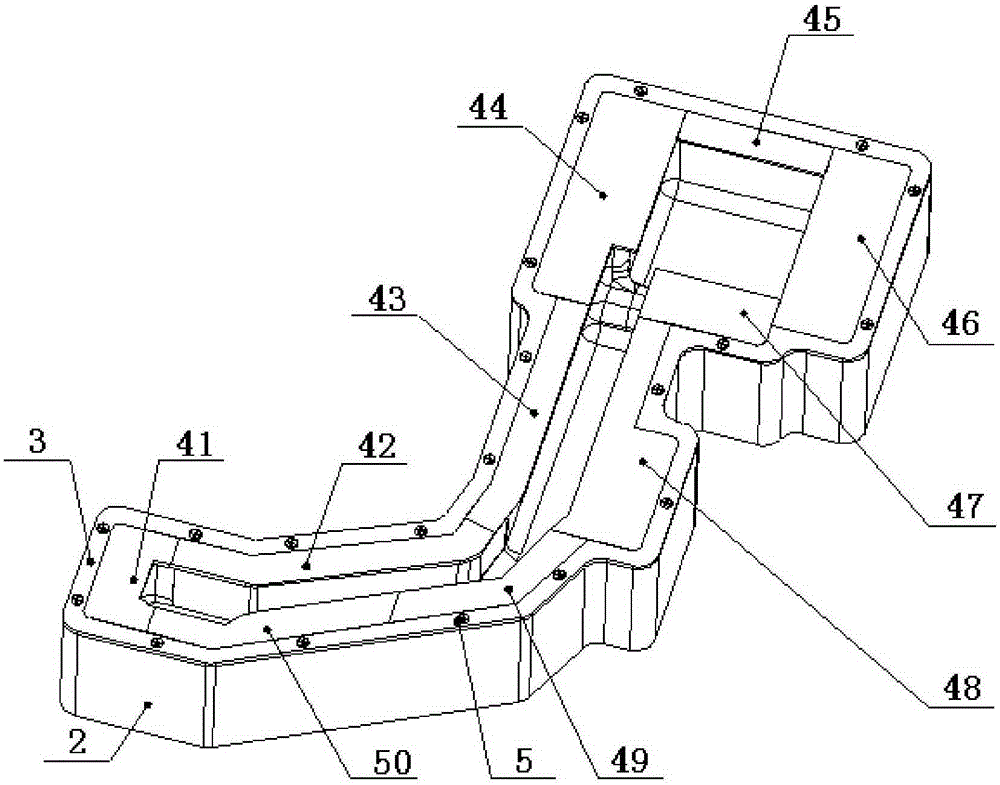

Sand core mold for large diesel engine high temperature cooler

ActiveCN103736918BSimple structureSolve the problem of smooth demouldingFoundry mouldsFoundry coresWear resistantEngineering

The invention discloses a mould of a high-temperature cooler sand core in a large diesel engine. The mould comprises a core box outer frame, a core box wear-resistant piece and a plurality of side surface loose pieces, wherein the core box outer frame comprises a bottom plate and a side wall extending upwards along the periphery of the bottom plate, the bottom plate and the side wall define a cavity of the high-temperature cooler sand core, and a plurality of yielding loose piece-shaped surfaces are arranged at the periphery of the cavity; the core box wear-resistant piece is designed to be matched with the top end of the side wall of the core box outer frame in shape and is fixedly arranged at the top end of the side wall of the core box outer frame; the side surface loose pieces are arranged in the yielding loose piece-shaped surfaces of the core box outer frame, and the inner side surfaces of the side surface loose pieces define a cavity side wall of the core box outer frame. According to the mould, the total weight of the mould can be reduced, the manufacturing cost can be saved, and the labor intensity can be lowered; a core box adopts a full-fall type loose piece structure, so that the mould can be released from a plurality of angles, the problem that the sand core cannot be smoothly demoulded is effectively solved, the operation is convenient and flexible, complete demoulding can be achieved, and the core-making efficiency is high; moreover, the made sand core is small in deformation and good in sizing precision.

Owner:GUANGXI YUCHAI MASCH CO LTD

A rapid core making mechanism and rapid core making method

Owner:SUZHOU MINGZHI TECH

Low-pressure casting method and device for thin-wall complex aluminum alloy gearbox shell

The invention discloses a low-pressure casting method and device for a thin-wall complex aluminum alloy gearbox shell, and belongs to the technical field of automobile accessory manufacturing, the device comprises a dead head, a sand core, a sprue and a loose core, a cylindrical feeding channel is formed in the sand core, an inner runner is arranged on the sprue, the sprue and the sand core are connected through matching of the cylindrical feeding channel and the inner runner, and the loose core is arranged in the inner runner. The inner runner is communicated with a bolt column of a casting, the loose core is arranged on the outer side of the sprue and the outer side of the sand core, the loose core is connected with an external pushing hydraulic cylinder, and the upper die, the lower die, the loose core and the sand core jointly form a forming die of the casting. The flange bolt boss adopts the comprehensive means of riser feeding, sequential solidification of castings in the low-pressure casting process is achieved, and the problems that the wall thicknesses of the castings are greatly different, the structure is complex, and poor forming and shrinkage porosity of products are prone to occurring are solved.

Owner:烟台路通精密科技股份有限公司

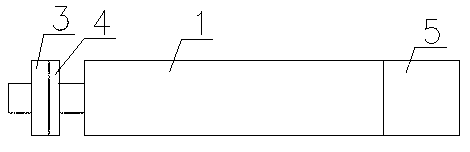

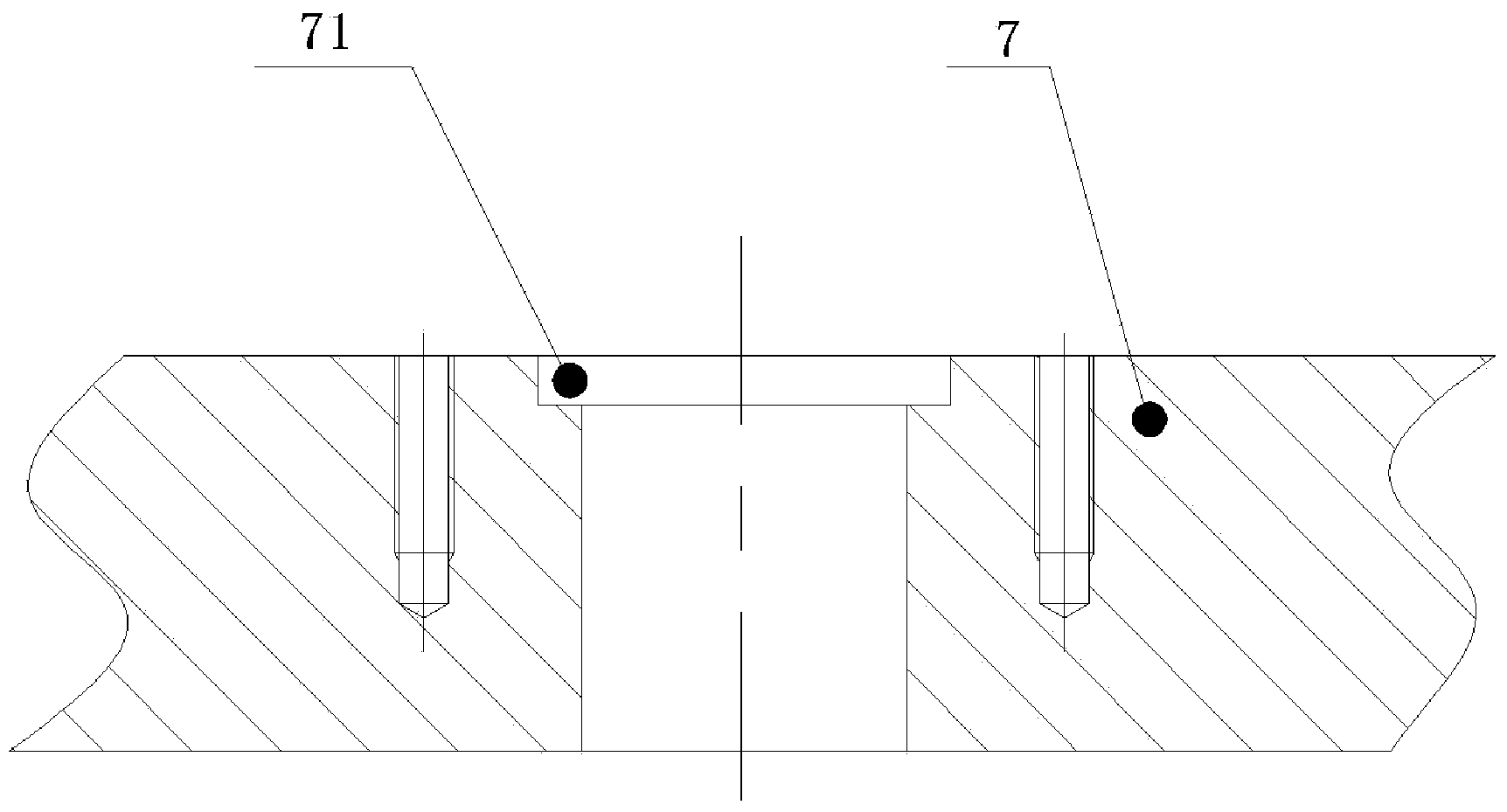

A plug-in sand injection nozzle with flexible installation of hot core box

ActiveCN106903272BOvercoming rigid mounting (traditional) structural inadequacies in flexibilityOvercoming lack of structural flexibilityMoulding machinesSand blastingMaterials science

The invention discloses an inserting-type sand blasting nozzle used for hot box flexible installation. The inserting-type sand blasting nozzle comprises a hot box sand blasting nozzle installation welding block (6), a sand blasting plate (1) which is welded with the welding block, a sand blasting nozzle cap (3), a sealing ring (4) and a sand stopping block (5). The inserting-type sand blasting nozzle is characterized in that the upper portion of a sand blasting nozzle body (2) is provided with a flange plate or an unthreaded rod, and the lower portion of the hot box sand blasting nozzle installation welding block (6) is provided with a groove matched with the flange plate or the unthreaded rod on the upper portion of the sand blasting nozzle body; the inner diameter of the groove is larger than that of the flange plate or the unthreaded rod by 1-2mm; and the sand blasting nozzle body, the welding block and the sand blasting plate are fixedly connected into a whole at the outer side of the groove through a screw (7) and a sand blasting nozzle limiting ring (8). By means of the inserting-type sand blasting nozzle used for hot box flexible installation, core-making efficiency of a hot box is improved, and by the adoption of a standard component connecting mode, the structure is simple and deflection is small; on one hand, the problems that an inserting-type sand blasting nozzle is prone to deformation and short in service life are solved; and on the other hand, the defects that the existing inserting-type sand blasting nozzle is large in using quantity of materials, high in installation structure manufacturing difficulty and low in efficiency are overcome.

Owner:南充市辉煌模具有限公司

Universal shot sand board

ActiveCN105798244BSand shooting pressure can be adjustedImprove core qualityMoulding machinesStructural engineeringManufacturing quality

Owner:江阴机械制造有限公司

Sand core box for bar casting and core making method

A stick type casting sand core box comprises a positioning bottom plate, a positioning top plate and a spliced type positioning side wall. The upper surface of the positioning bottom plate is provided with a lower positioning groove, the lower surface of the positioning top plate is provided with an upper positioning groove, and the spliced type positioning side wall is a hollow cylinder. The top of the spliced type positioning side wall is embedded into the upper positioning groove of the positioning top plate, and the bottom of the spliced type positioning side wall is embedded into the lower positioning groove of the positioning bottom plate. The spliced type positioning side wall comprises a plurality of pieces of core iron, the core iron is provided with an arc-shaped body, the core iron is arrayed in the circumferential direction to form the spliced type positioning side wall, and the adjacent core iron does not make contact so that receding gaps can be formed. According to the core box, by manufacturing the blocky and independent core iron, the core box structure is simplified, placement of a large number of chilling blocks in the core manufacturing process is avoided, and the core manufacturing efficiency is improved. The core iron has the effect of the chilling blocks and forms the side wall of the core box, and a double beneficial effect is achieved.

Owner:KOCEL EQUIP

Large Diesel Engine Air Cooler Sand Core Mould

ActiveCN103736919BSimple structureSolve the problem of smooth demouldingFoundry mouldsFoundry coresEngineeringUltimate tensile strength

The invention discloses a sand core mould of an air cooler sand core in a large diesel engine. The sand core mould comprises an upper core box, a lower core box and a plurality of side surface loose pieces, wherein the upper core box is provided with an upper cavity of the air cooler sand core; a lower cavity of the air cooler sand core, which is matched with the upper cavity of the upper core box and is provided with a plurality of yielding loose piece-shaped surfaces, is formed in the lower core box; the side surface loose pieces are arranged in the yielding loose piece-shaped surfaces of the lower core box. According to the mould, the structure is simple and reasonable, each core box is made of a cast iron material, the shape of the periphery of the core box is designed to be matched with the sand core, and the total weight of the mould can be reduced and the manufacturing cost can be saved while the strength of the core box is guaranteed and the deformation is prevented; the local part of the core box adopts a loose piece structure, so that the problem that the sand core cannot be smoothly demoulded is effectively solved, the operation is convenient and flexible, and the core-making efficiency is high; moreover, the made sand core is small in deformation and good in sizing precision.

Owner:GUANGXI YUCHAI MASCH CO LTD

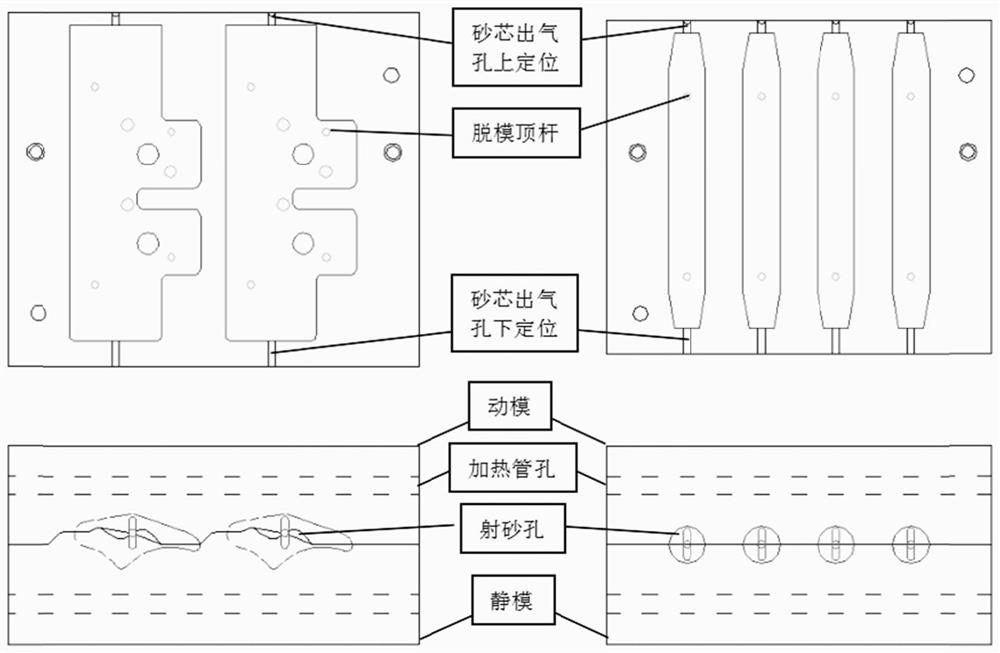

Manufacturing process of sand core of precoated sand for coupler knuckle of locomotive coupler

PendingCN114082900AReduce sand inclusionsReduce cavity penetrationFoundry mouldsMoulding machinesManufacturing technologyWaste product

The invention relates to the technical field of locomotive coupler knuckles, in particular to a manufacturing process of a sand core of of precoated sand for a coupler knuckle of a locomotive coupler. The manufacturing process comprises the following steps of: S1, determining a hot core box process to manufacture a core, namely aiming at the characteristic of long hardening time of alkali phenolic resin self-hardening sand, using the hot core box process in a coupler knuckle core manufacturing method, and using precoated sand as a core manufacturing material; and S2, designing a hot core box specific structure, specifically, a weight reduction cavity F-shaped sand core hot core box is used for discharging two sand cores from one core box, and a coupler knuckle pin hole sand core hot core box is used for discharging four sand cores from one core box. The manufacturing process is applied to locomotive coupler knuckle production, the core manufacturing efficiency of the sand core of the coupler knuckle is improved, the manufacturing cost is reduced, and extremely considerable economic benefits are created; in addition, after the manufacturing process is adopted, the casting defects of sand inclusion, cavity penetration, core expansion, air holding and the like of the coupler knuckle are obviously reduced, a large amount of waste loss and defective product rescue cost are saved, and along with popularization of the manufacturing process, other large-batch small castings can also refer to related technologies, so that the production efficiency and quality are improved.

Owner:CRRC DALIAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com