Novel structure for enhancing conduction efficiency of casting hot core box

A technology of conduction efficiency and casting heat, which is applied in the direction of casting molding equipment, etc., can solve the problems of insufficient solidification of sand cores, prolong the curing time, and reduce production efficiency, so as to increase heat conduction efficiency, improve core-making efficiency, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

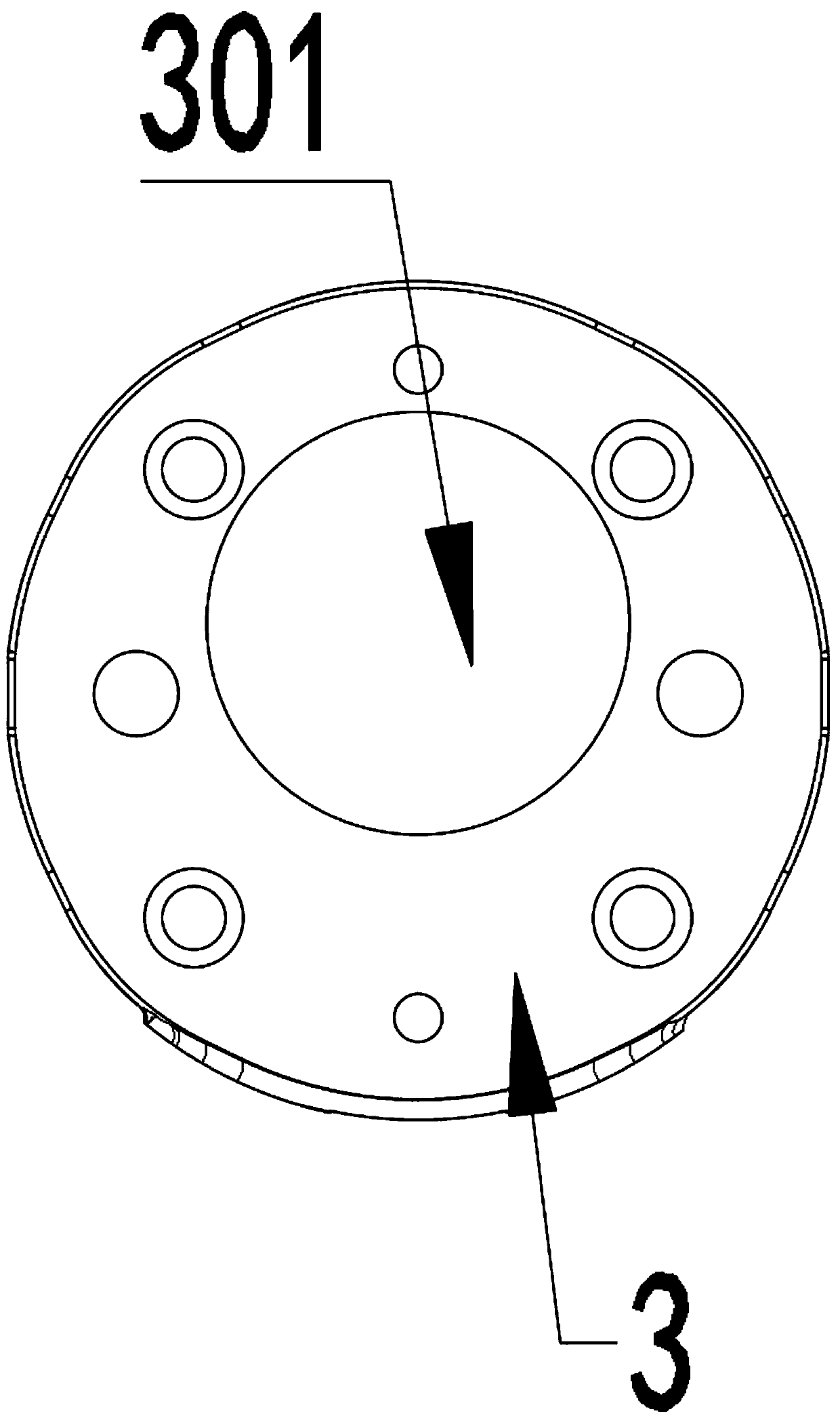

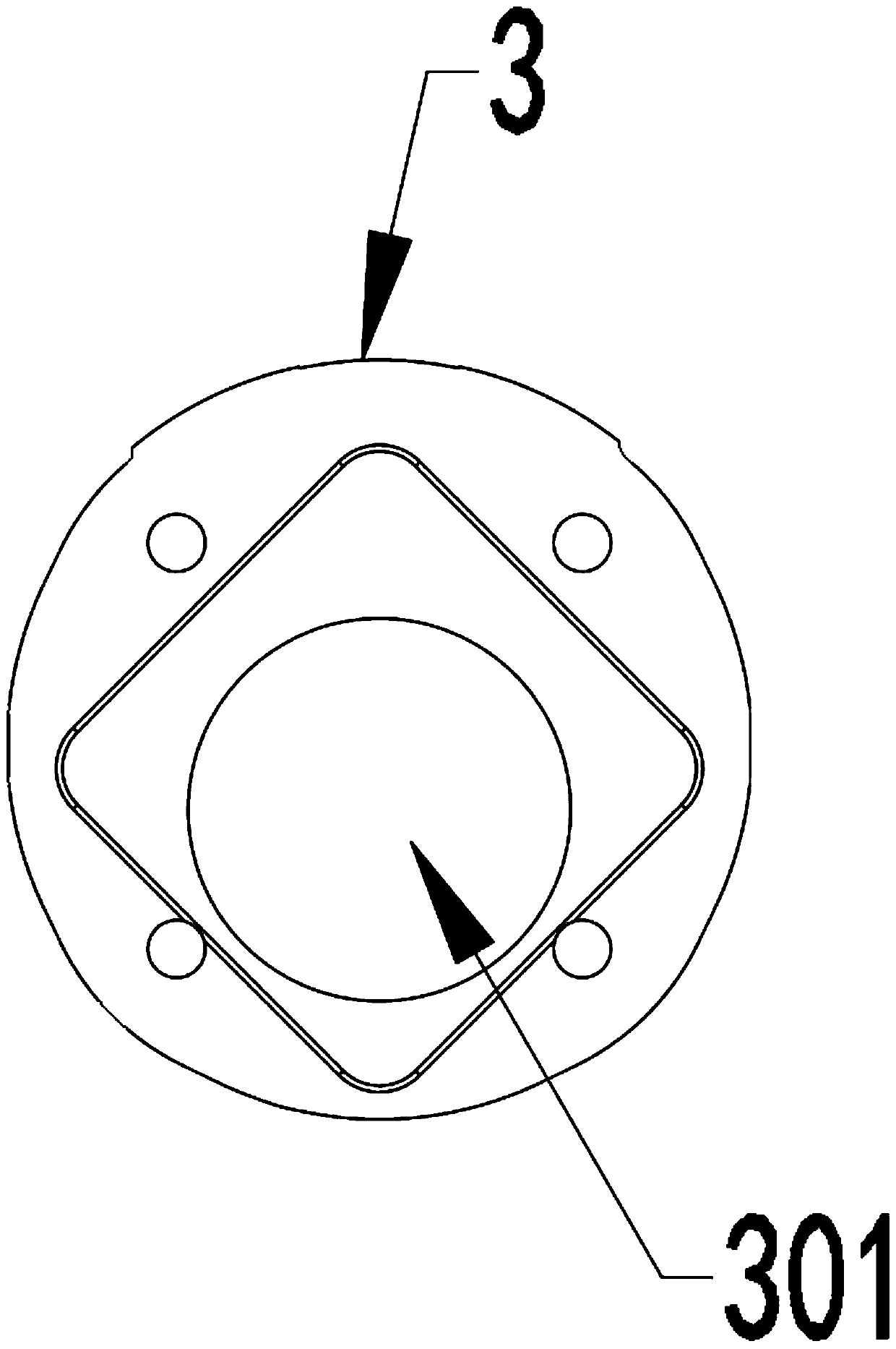

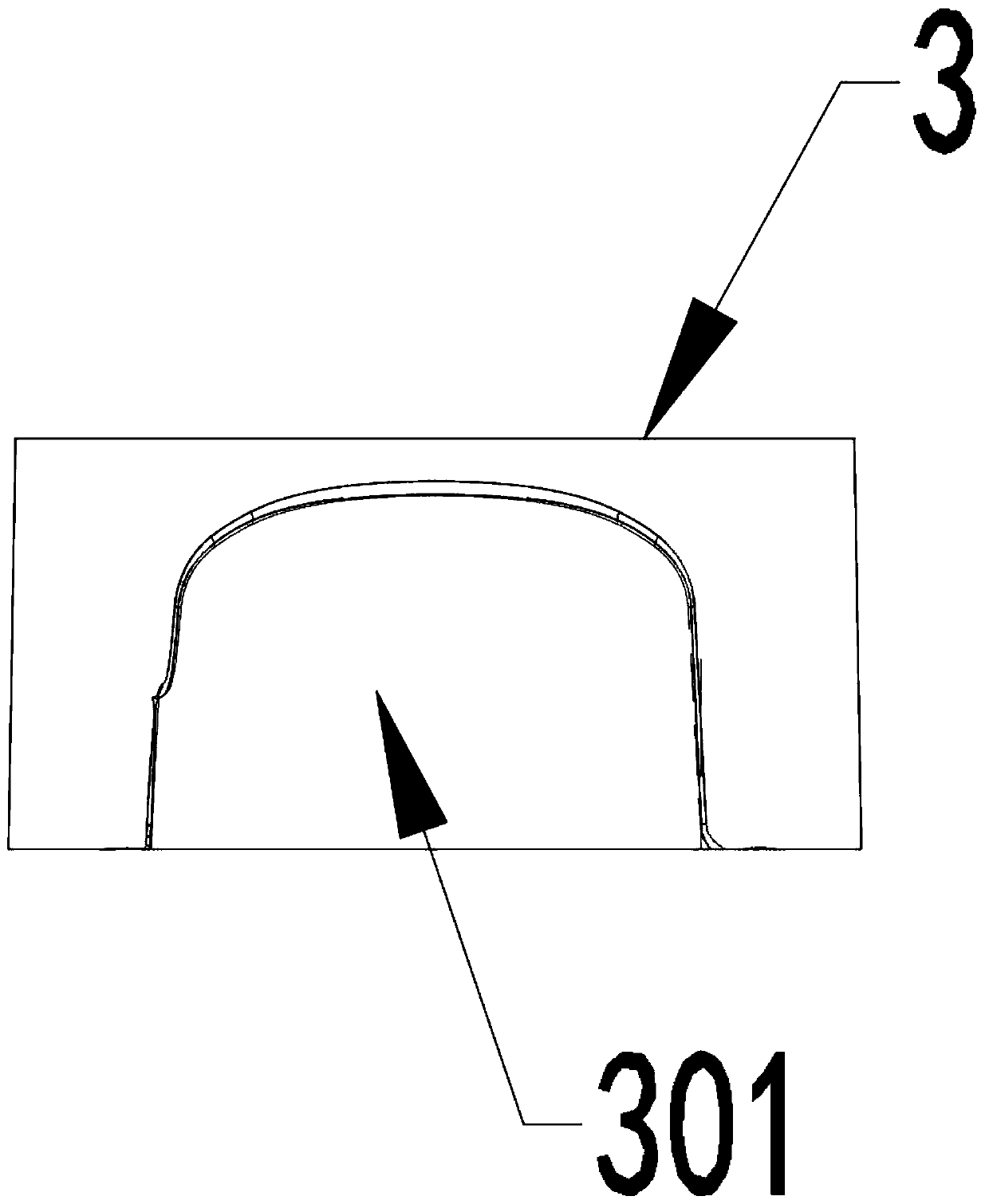

[0022] as attached figure 1 To attach Figure 4 Shown:

[0023] The present invention provides a novel structure for enhancing the conduction efficiency of a casting hot core box, comprising: an upper core box body 1, an upper core box cup mounting groove 2, an upper core box cup 3 and a copper rod fixing hole 301; the upper core box The upper side of the body 1 is provided with six upper core box cup installation grooves 2; the inner side of the upper core box cup installation groove 2 is embedded and fixed with six upper core box cups 3.

[0024] Wherein, the upper core box cup 3 is provided with an eccentric copper rod fixing hole 301, and the copper rod fixing hole 301 is embedded with a heat-conducting copper rod, and the heat-conducting copper rod needs to be tightly fitted in the copper rod fixing hole 301. Structure A large copper rod is embedded in the copper rod fixing hole 301 in the upper core box cup 3 of the solid mold steel structure, which is convenient for i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com