Manufacturing device of knock-off core and manufacturing method thereof

A technology of easy-to-cut pieces and equipment, which is applied in the direction of casting molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, high power consumption, and inability to guarantee production volume, and achieve simple operation, reduce labor intensity, and guarantee quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

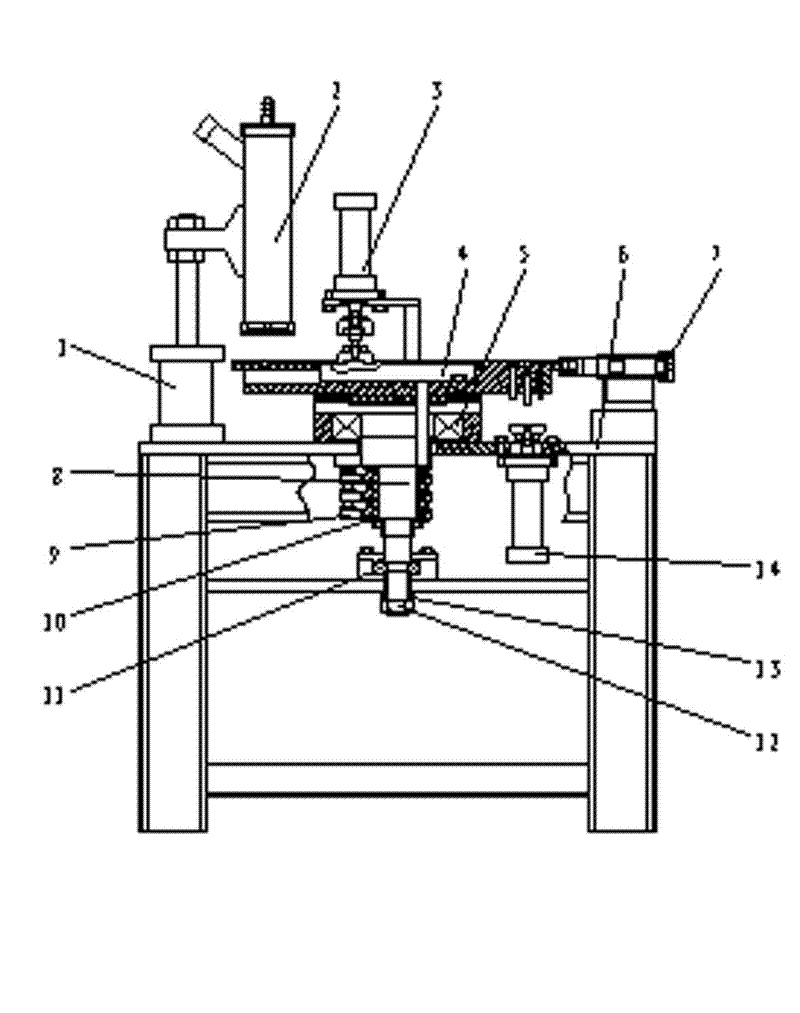

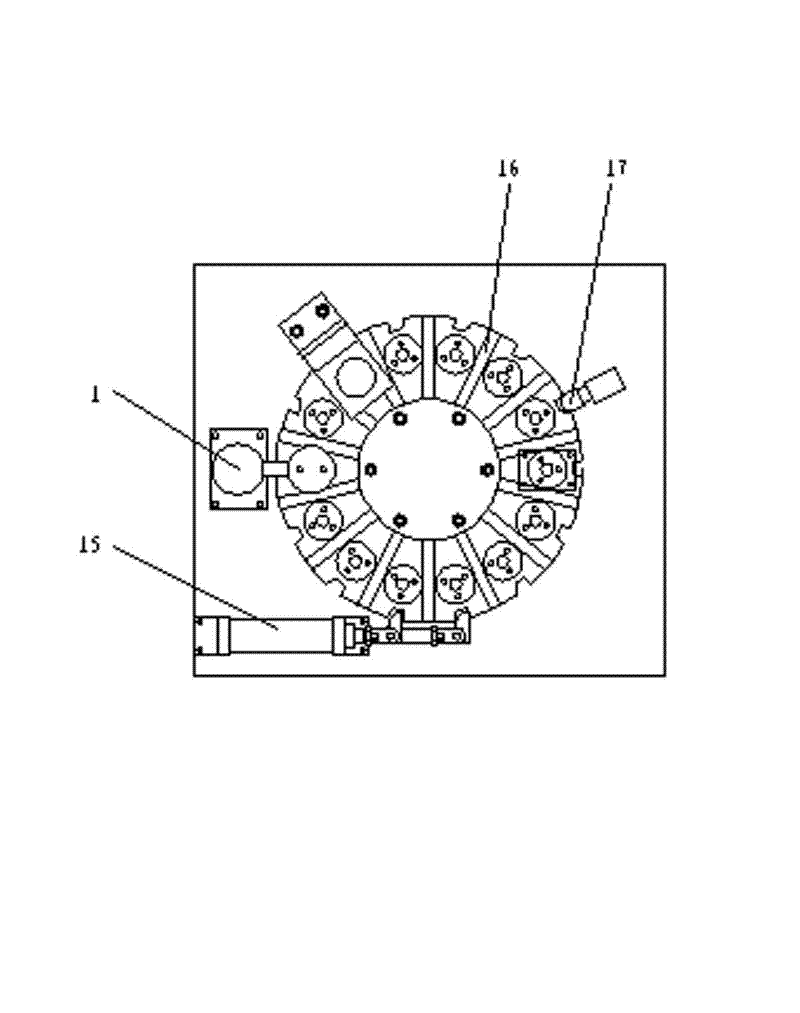

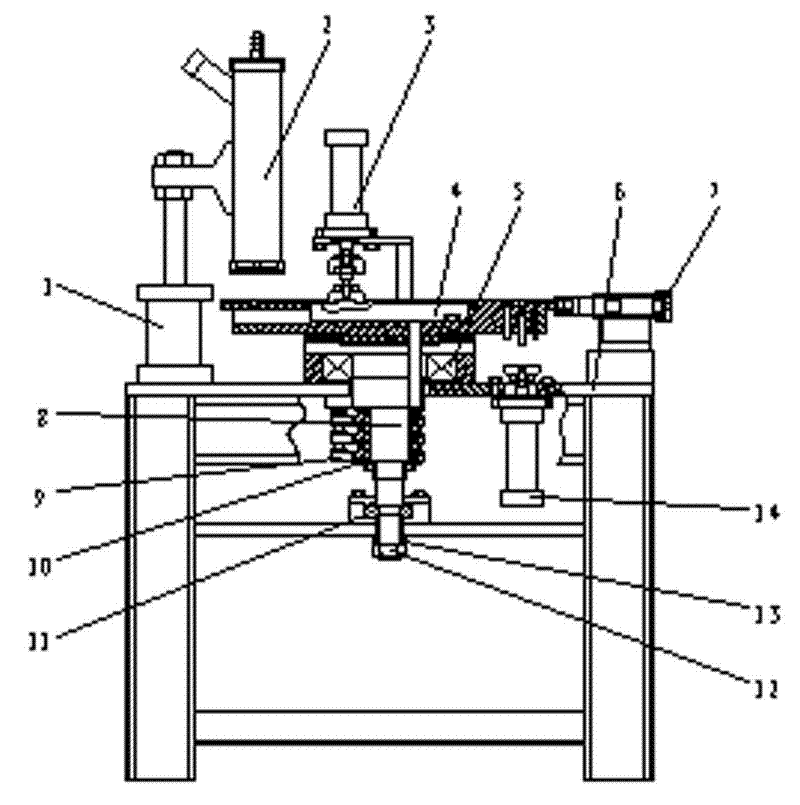

[0018] see figure 1 and figure 2 , a kind of riser easy-cut sheet production equipment, a sand-shooting cylinder 1 is installed on the side above the frame, the sand-shooting cylinder 1 is connected with a sand-shooting cylinder 2, and a 14-station is installed in the middle above the frame The reset cylinder 3 controlled by the rotary mold 4 is equipped with a rotating shaft 8 below the reset cylinder 3, and the two ends of the rotating shaft 8 are respectively sleeved in the 7222 bearing 5 and the 8106 bearing 13, and a slip ring 10 is sleeved on the outer circumference of the rotating shaft 8. A carbon brush holder 9 is installed on the slip ring 10, and an adjusting nut 12 is installed under the rotating shaft 8. One end of the adjusting nut 12 is set in the 42207 bearing 11, and a positioning cylinder 7 is installed on the other side above the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com