Multifunctional locking mechanism for sand core and core manufacturing method

A locking mechanism and multi-functional technology, applied in the field of casting molds, can solve problems such as the inability to meet the requirements of new core-making equipment, and achieve the effects of improving operation controllability, stable and reliable process, and small damage to sand cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

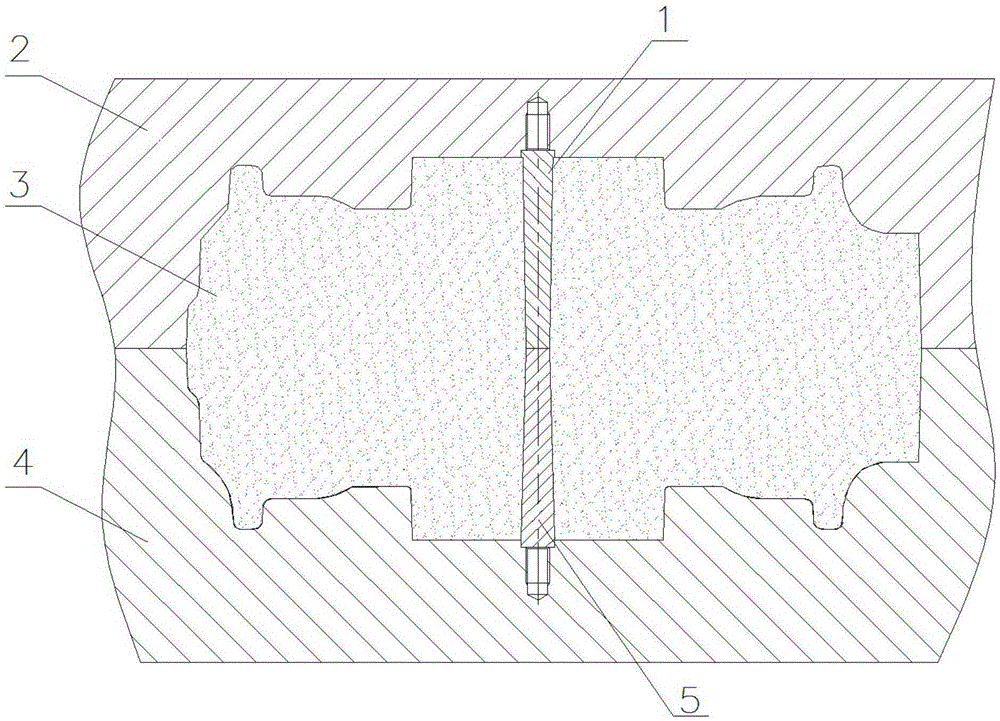

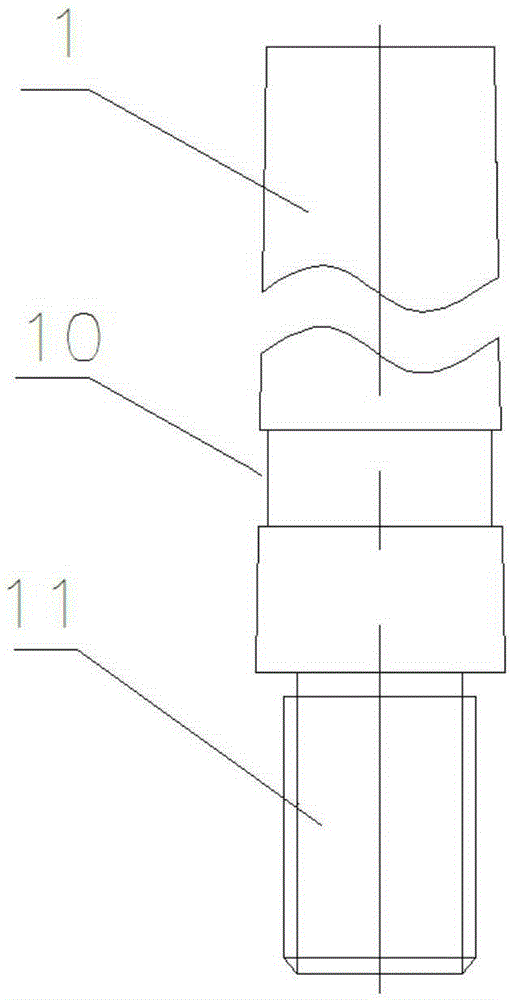

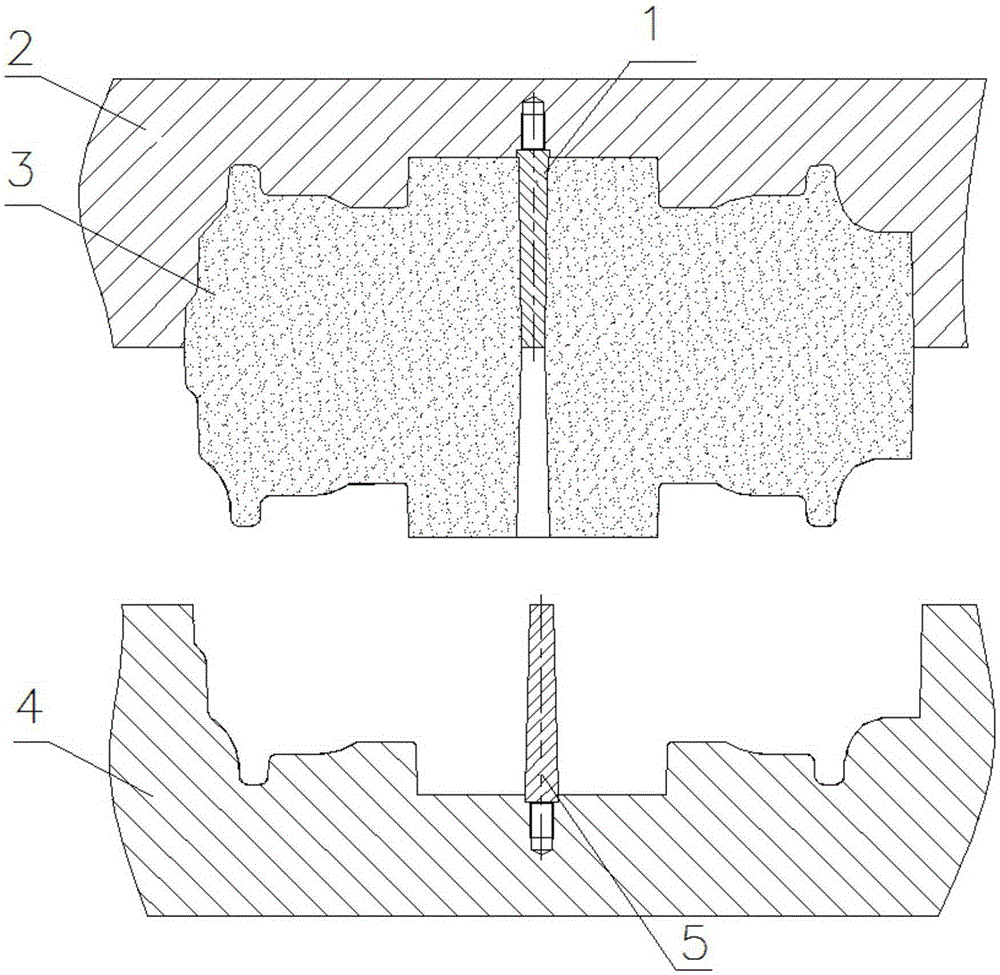

[0036] Such as Figure 1 ~ Figure 4 as well as Figure 9 As shown, a multi-functional sand core locking mechanism includes an upper core box 2 and a lower core box 4, the first group of core screw hole patterns 1 are vertically arranged in the upper core box 2, and the lower core box 2 is vertically arranged. Inside the core box 4, there is a second group of core screw hole patterns 5 arranged vertically. The first group of core screw hole patterns 1 is also provided with a position close to the upper core box 2 for locking and fixing the sand core 3 on the The groove 10 on the upper core box 2, the first set of core screw hole pattern 1 has a draft angle. In this embodiment, the groove 10 is an annular groove.

[0037] Specifically, the depth of the groove 10 is 0.4 mm, the height of the groove 10 is 8 mm, and the draft angle of the first core screw hole pattern 1 is 1°. Specifically, the draft angle of the first group of core screw hole patterns 1, the depth of the groove...

Embodiment 2

[0048] This embodiment is substantially the same as Embodiment 1, except that the depth of the groove 10 is 0.6 mm, the height of the groove 10 is 10 mm, and the draft angle of the first group of core screw hole pattern 1 is Angle is 2°, and the draft angles of the second group of core screw hole pattern 5, upper core box 2 and lower core box 4 are 2° respectively.

[0049] Through 100 sets of repeated tests, it was confirmed that the multi-functional sand core locking mechanism did not fall off when the lower core box 4 was ejected, and the sand core damage rate was 0 when the upper core box 2 was ejected.

Embodiment 3

[0051] This embodiment is substantially the same as Embodiment 1, except that the depth of the groove 10 is 0.9 mm, the height of the groove 10 is 12 mm, and the draft angle of the first group of core screw hole pattern 1 is Angle is 3°, and the draft angles of the second group of core screw hole pattern 5, upper core box 2 and lower core box 4 are 3° respectively.

[0052] Through 100 sets of repeated tests, it was confirmed that the multi-functional sand core locking mechanism did not fall off when the lower core box 4 was ejected, and the sand core damage rate was 0 when the upper core box 2 was ejected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Draft angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com