A rapid core making mechanism and rapid core making method

A fast, core box technology, applied in the direction of molding machines, manufacturing tools, casting molding equipment, etc., can solve the problems of not making full use of core making machines and reducing core making efficiency, so as to save core making equipment, improve core making efficiency, The effect of reducing the time of the empty loop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

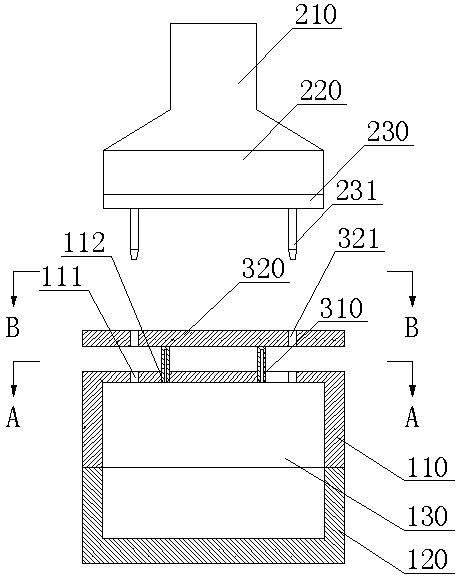

[0026] Embodiment one: see Figure 1-Figure 3 , as shown in the legend therein, is a rapid core-making mechanism, which includes a core box device, a sand shooting device and an air blowing / core ejecting device.

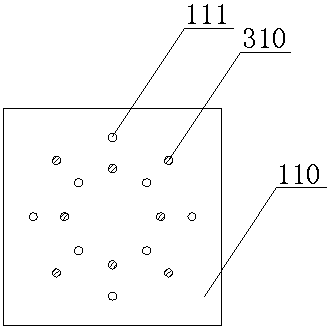

[0027] The above-mentioned core box device includes an upper core box 110 and a lower core box 120. The upper core box 110 has a core box top wall, and the core box top wall is provided with eight through-holes for sand shooting 111 and eight blowing / core holes. 112, eight sand shooting holes 111 and eight blowing / core holes 112 are set in a staggered manner.

[0028] The above-mentioned sand-shooting device includes a sand-shooting cylinder 210, a sand-shooting head 220 and a sand-shooting plate 230. The above-mentioned sand-shooting device is movable up and down above the top wall of the core box. The sand-shooting plate 230 is provided with eight sand-shooting holes. 111 correspond to eight sand nozzles 231 up and down.

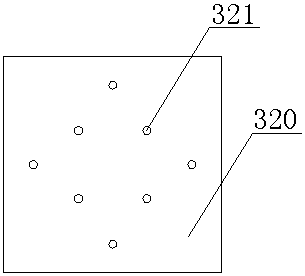

[0029] The above-mentioned air blowing / c...

Embodiment 2

[0038] see Figure 4 to Figure 6 , as shown in the legend, the rest is the same as the first embodiment, the difference is that the rapid core making mechanism also includes a sealing plate 400, and the sealing plate 400 includes a through hole that passes through its upper and lower sides and matches the sand shooting nozzle 231. The hole 410 and the sealing plate 400 have the degree of freedom to rotate with the air blowing plate 320 on the horizontal plane. The through hole 410 and the avoidance hole 321 are completely staggered up and down or the through hole 410 and the escape hole 321 are completely connected up and down.

[0039] The above settings ensure that the mold cavity 130 remains in a sealed state when blowing and solidifying. There is also a transition step between step (3) and step (4). The transition step is as follows. Movement, the sand shooting nozzle 231 breaks away from the sand shooting hole 111 and the escape hole 321, and the sealing plate 400 rotates...

Embodiment 3

[0042] The rest is the same as the second embodiment, except that the above-mentioned sealing plate has a degree of freedom for translational movement with the above-mentioned blowing plate on the horizontal plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com