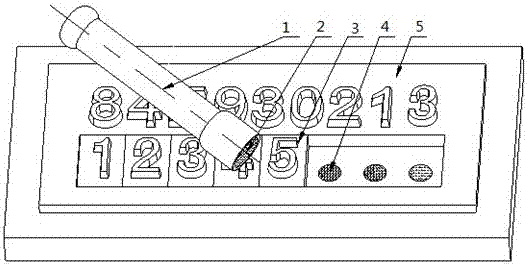

Positioning and taking-out device for movable types in die cavity

A technology for taking out devices and movable type, which is applied in the direction of tools, casting molds, and cores, etc. It can solve the problems of large number of movable types, cumbersome operation, and reduced mold core-making efficiency, so as to achieve flexible replacement, reduce cumbersome procedures, and improve core-making efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Use 45# steel to process the movable type, and process the movable type positioning groove at the corresponding position of the mold cavity, install the positioning magnet in the positioning groove, assemble the movable type into the positioning groove, and fix the movable type through the positioning magnet, so that the movable type will not be lost every time It is taken out when the mold is lifted for the first time; a strong magnet handle is made, and the strong magnet handle is used to take out the movable type when the movable type needs to be replaced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com