Universal shot sand board

A sand-shooting board, general-purpose technology, applied in molding machines, casting molding equipment, metal processing equipment, etc., can solve the problems of waste of mold making time and cost, non-adjustable sand-shooting pressure, and inevitable leakage of coated sand, etc. Achieve the effects of improving core-making quality and production efficiency, saving mold opening time and cost, and adjusting sand shooting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

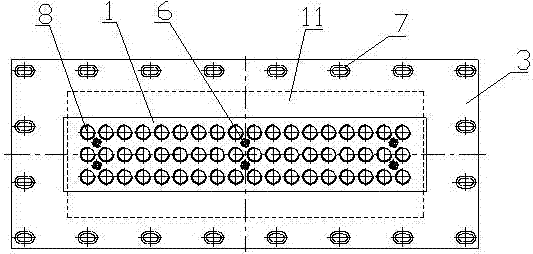

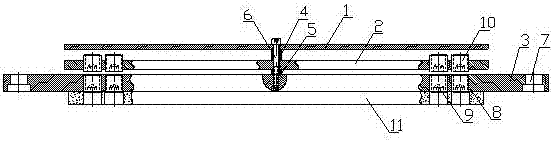

[0017] see figure 1 with figure 2 , the present invention relates to a general-purpose sand shooting board, which includes a limit baffle 1, a bracket 2, and a main board 3 of the sand shooting board from top to bottom, and a limit stop is set between the limit baffle 1 and the bracket 2. Spacer 4, the limit spacer 4 makes the limit baffle 1 and the support 2 have a gap, the support spacer 5 is arranged between the support 2 and the main board 3 of the sand shooting board, and the height of the support spacer 5 is 5~8mm , the support block 5 makes the support 2 and the main board 3 of the sand shooting board have a gap, and the connecting bolt 6 passes through the limit baffle 1, the limit block 4, the support 2, the support block 5 to the shot sand from top to bottom in sequence. In the main board 3 of the sand shooting board, a ring of 20 sand cylinder connecting bolt holes 7 in total is arranged on the edge of the main board 3 of the sand shooting board. The connecting bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com