Production process for manufacturing transformer iron core through 3D printing technology

A production process and 3D printing technology, applied in the field of transformer manufacturing, can solve the problems of long labor hours, low labor productivity, and long production period, so as to reduce the risk of safe operation, improve the magnetic induction ability, and avoid the effect of artificial production deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

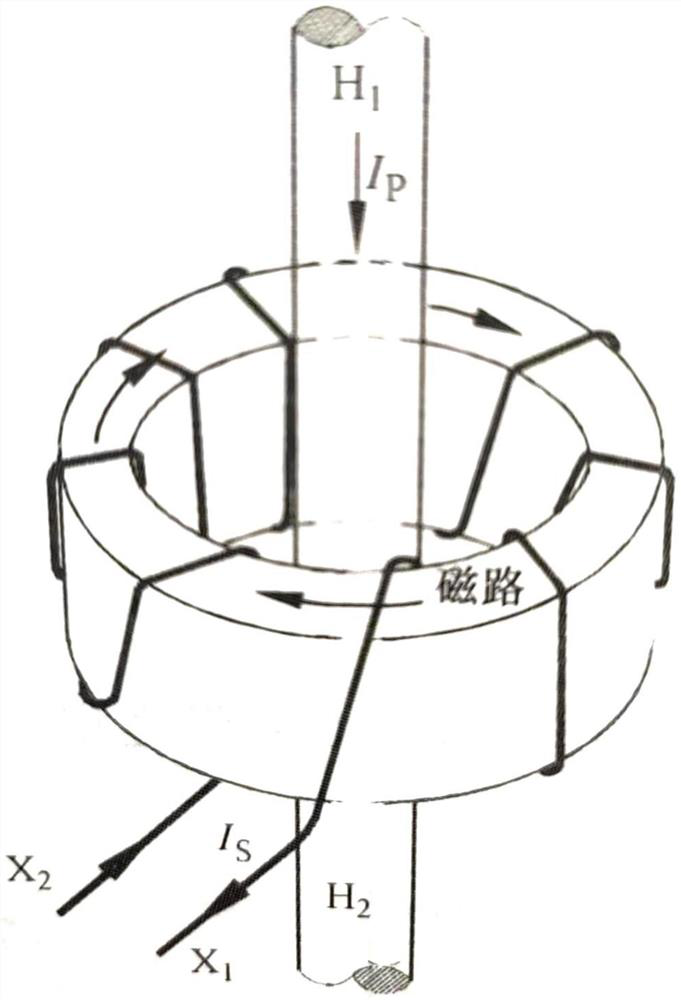

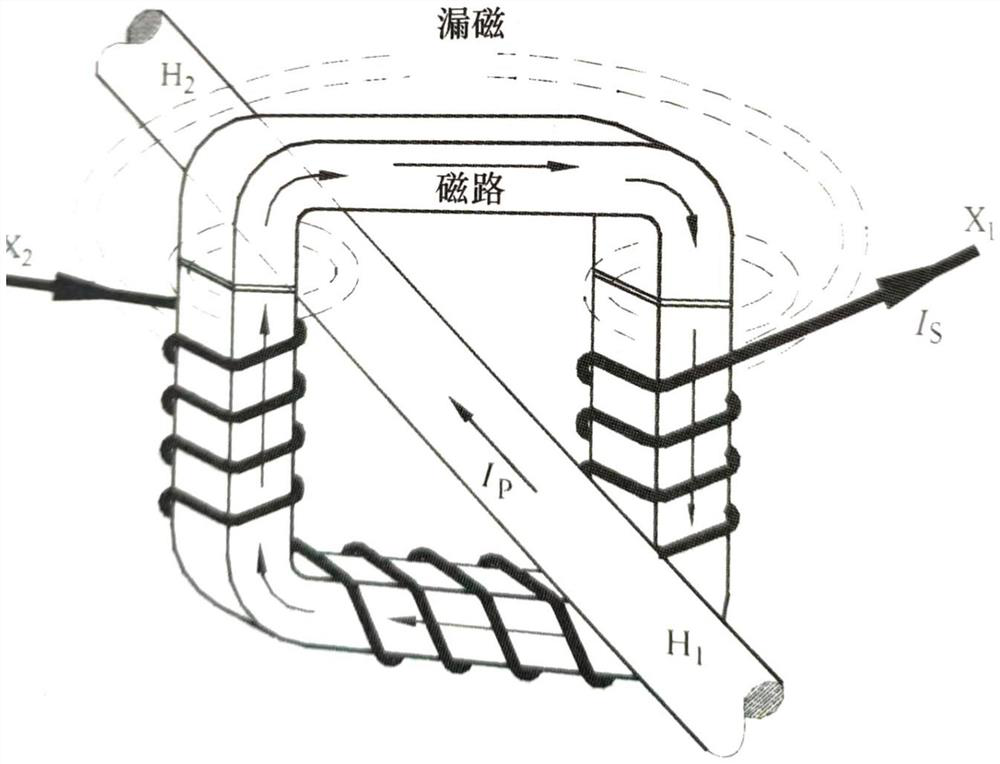

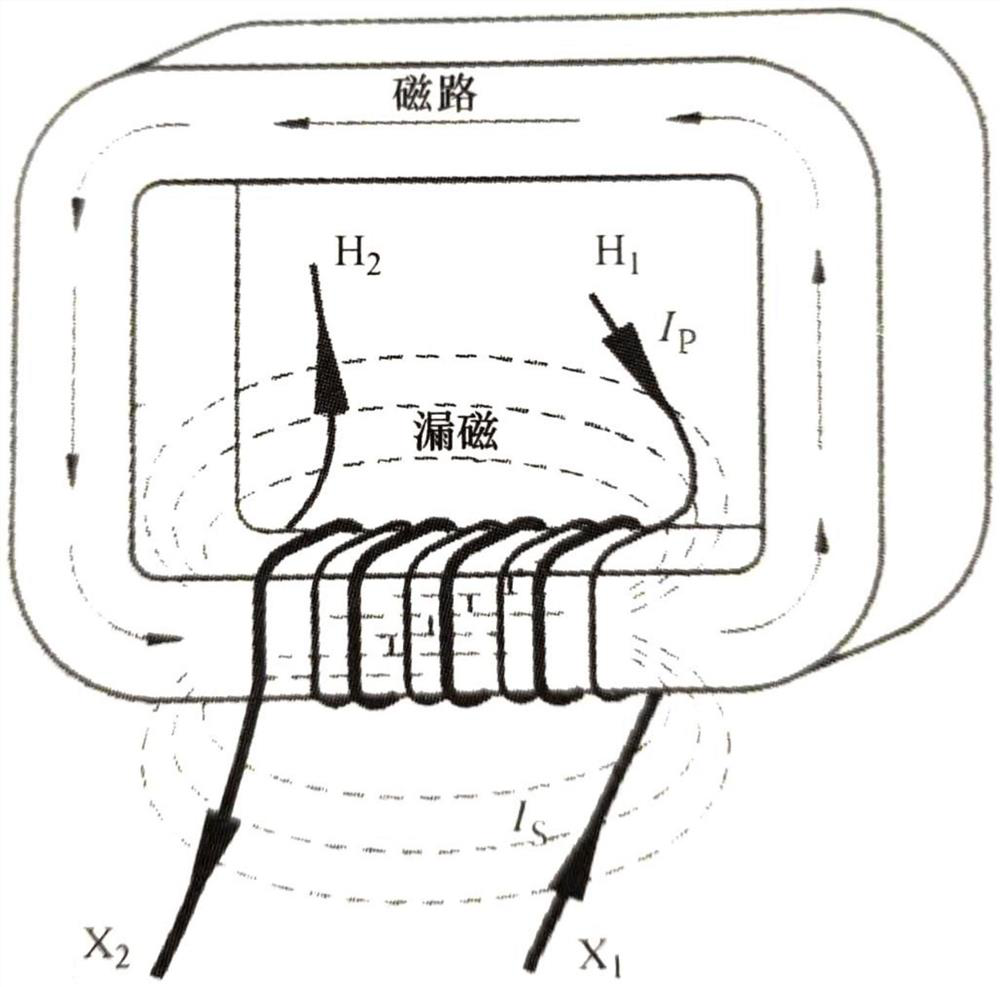

[0030] A production process for manufacturing transformer cores using 3D printing technology will be further described in detail below in conjunction with the accompanying drawings.

[0031] Combined with the accompanying drawings, Figure 1~4 , a production process for making a transformer core using 3D printing technology, the specific steps of the production process include:

[0032] Step 1: Use computer modeling software to model the three-dimensional model of the transformer core, and divide the built three-dimensional model into layer-by-layer sections, which are used to guide the 3D printer to print layer by layer;

[0033] Step 2: Using non-dried pot electrode melting technology, electrolysis technology, and high-cooling technology, an appropriate amount of magnetic materials are prepared into metal and magnetic fine particles;

[0034] Step 3: The 3D printer reads the cross-section data in step 1, uses the metal powder material in step 2 to print the cross-section ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com