Efficient core manufacturing method for blowing and hardening sodium silicate-bonded sand

A technology of water glass sand and air hardening, which is applied in the direction of cores, manufacturing tools, casting molding equipment, etc., which can solve the problems of low production efficiency, long blowing time, and inability to meet high-efficiency core making, so as to achieve less and less air hole defects. Blowing time, beneficial to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

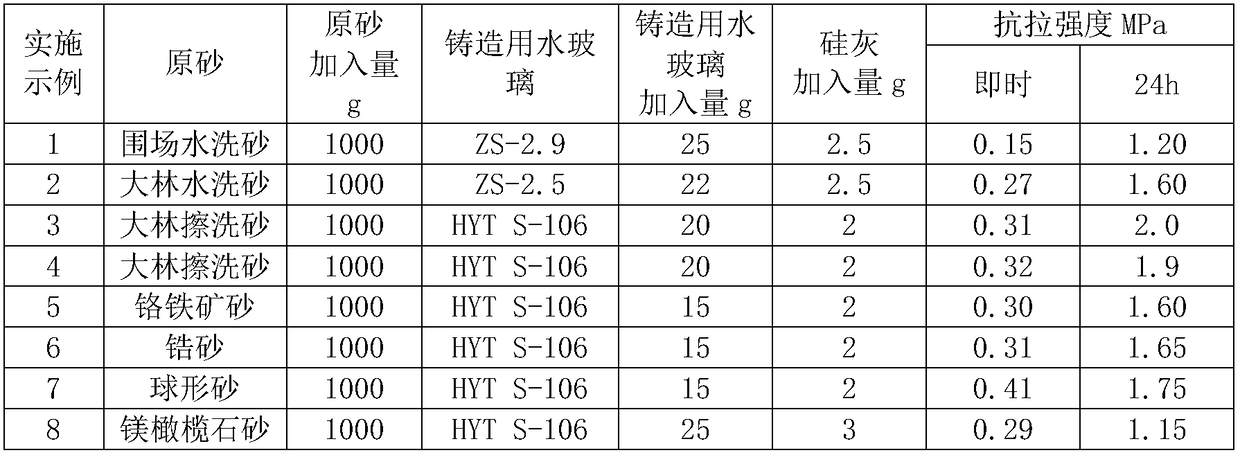

Examples

Embodiment 1

[0028] Adopt Suzhou Mingzhi Technology Co., Ltd. MLWA1 sample mechanism movement. Turn on the mold electric heating system, and control the heating temperature at 40±5°C. Then configure the core sand mixture and mix it with a laboratory blade sand mixer, put the core sand mixture into the sand shooting cylinder, and inject the core sand mixture into the standard "8" type sample at 0.4Mpa with compressed air Experimental mold cavity, the core box mold descends with the main cylinder, pushes the blowing plate to the top of the mold, the main cylinder rises, and presses the blowing plate tightly; start the blowing valve, and at 0.15Mpa, the CO 2 The gas is blown into the cavity of the sand core through the blowing plate, and the air is blown for 12s; 2 The gas pipeline connects the compressed air to the blowing plate of the mold, blows the compressed air into the cavity of the sand core under the pressure of 0.2Mpa, and blows the compressed air for 20s. Only one sand core, thre...

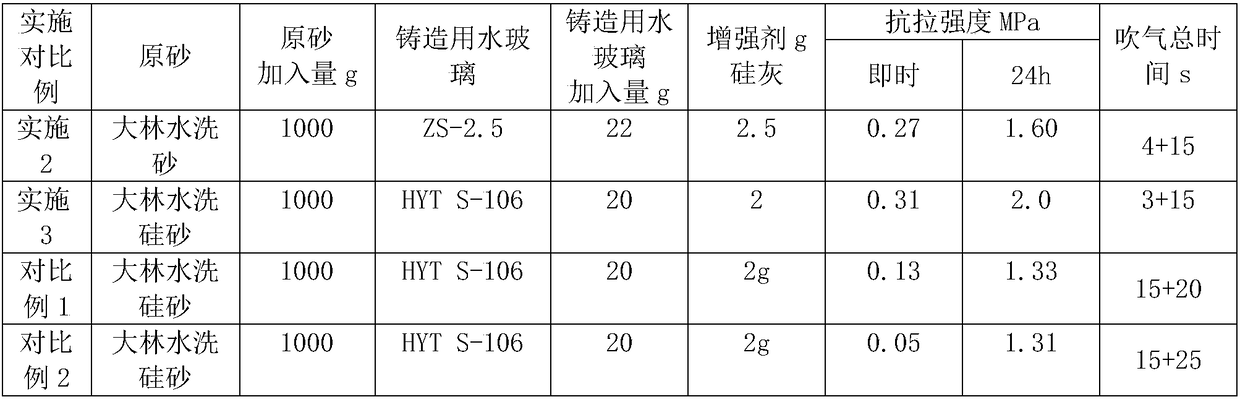

Embodiment 2

[0031]Adopt Suzhou Mingzhi Technology Co., Ltd. MLWA1 sample mechanism movement. Turn on the mold electric heating system, and control the heating temperature at 50±5°C.

[0032] Proportion of core-making mixture: Dalin washed sand 1000g, ZS-2.5 modulus 2.2, casting water glass 22g, silica fume 2.5g, mix with a laboratory blade sand mixer, put the core-making sand mixture into the sand shooting cylinder , at 0.5Mpa, use compressed air to inject the core-making sand mixture into the cavity of the standard "8" sample experimental mold, the core box mold will descend with the main cylinder, push the air blowing plate to the top of the mold, the main cylinder will rise, and Press the blowing plate tightly; start the blowing valve, under 0.1Mpa, the CO 2 The gas is blown into the cavity of the sand core through the blowing plate, and the blowing time is 4s; 2 The gas pipeline connects the compressed air to the blowing plate of the mold, blows the compressed air into the cavity of...

Embodiment 3

[0034] Adopt Suzhou Mingzhi Technology Co., Ltd. MLWA1 sample mechanism movement. Turn on the mold electric heating system, and control the heating temperature at 55±5°C.

[0035] Proportion of core-making mixture: Dalin scrubbing sand 1000g, casting water glass HYT S-106 for ester curing: 20g, silica fume 2g, mix with a laboratory blade sand mixer, put the core-making sand mixture into the sand shooting cylinder, At 0.5Mpa, use compressed air to inject the core-making sand mixture into the cavity of the standard "8" sample experimental mold. The core box mold descends with the main cylinder, pushes the air blowing plate to the top of the mold, and the main cylinder rises to blow the air. The air plate is pressed tightly; the blow valve is activated, and the CO 2 The gas is blown into the cavity of the sand core through the blowing plate, blowing for 3 seconds, after the blowing is completed, immediately start the ventilation valve and close the CO 2 The gas pipeline connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com