Robot type casting core with long rocker

A robot and mud core technology, applied in the field of casting mud cores, can solve the problems of green mold sand with great influence on performance, failure to meet production requirements, and low core-making efficiency, so as to reduce labor intensity of workers, improve core-making efficiency, and The effect of high core efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

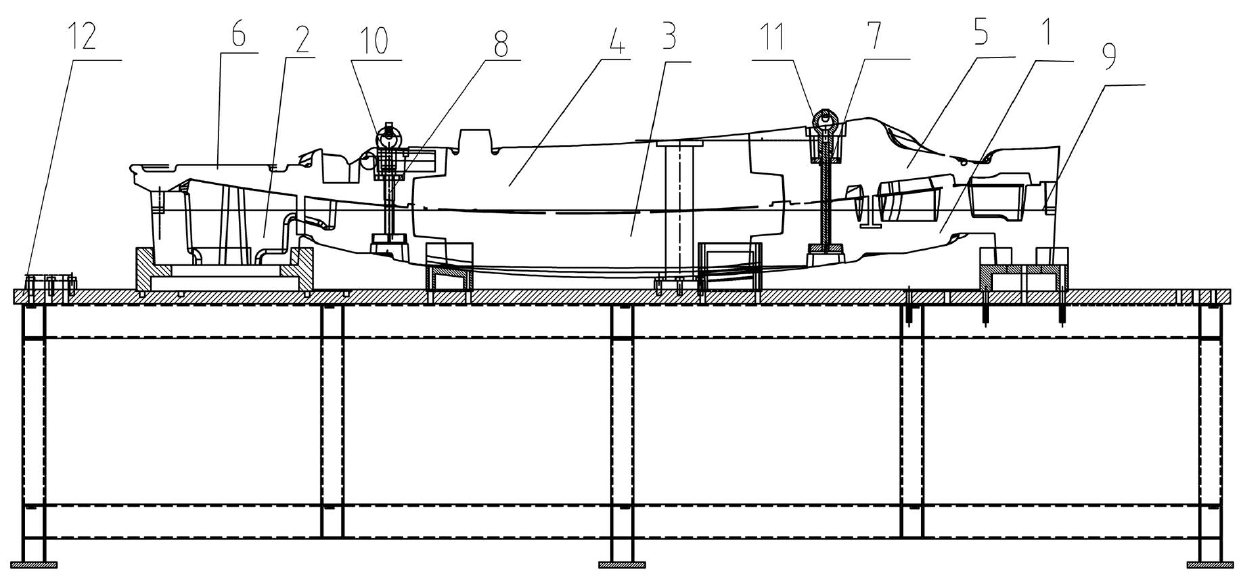

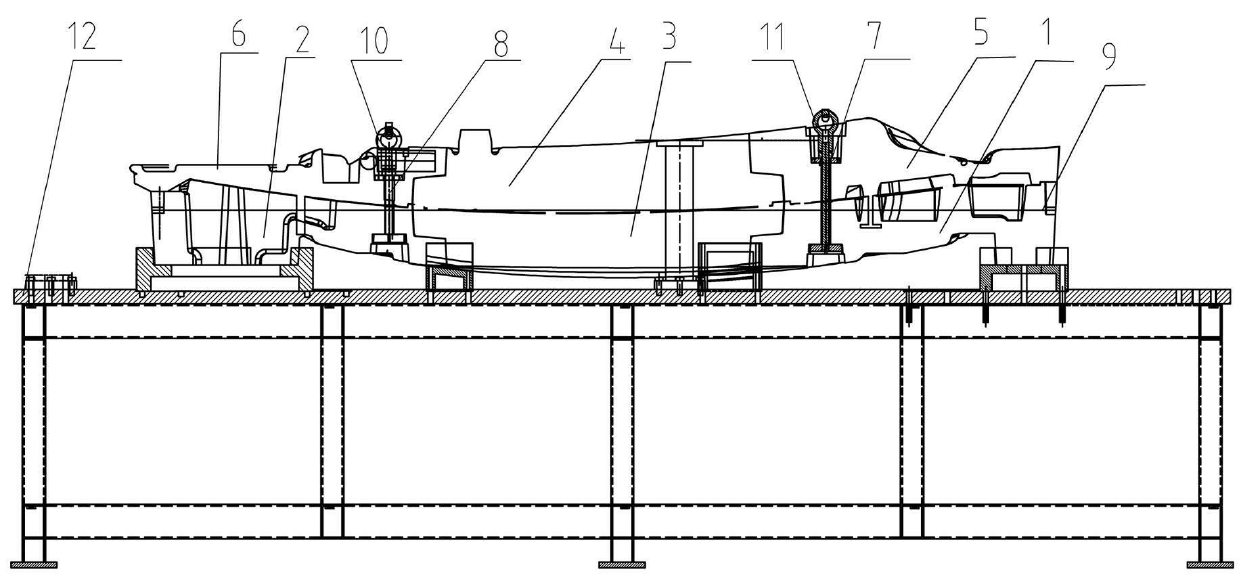

[0013] Such as figure 1 As shown, a robot long rocker casting clay core, it includes the rocker lower core No. 3 core 3, the two sides of the No. 3 core are respectively engaged with the turntable lower core No. The upper part of No. 2 core, No. 2 core and No. 3 core is respectively provided with interlocking turntable core 5, core 5, arm core 6, core 6 and rocker core 4, core 4, core 1 and core 5. The second vertical fastening device 7 is provided between them, the first vertical fastening device 8 is provided between the No. 2 core and the No. 6 core, and the No. 1 core, No. 2 core, and No. The interface between No. 6 core, No. 6 core and No. 4 core is provided with a horizontal fastening device 9, and the top ends of the first vertical fastening device and the second vertical fastening device are respectively provided with a first suspension ring 10 and a second vertical fastening device. Two rings 11. Preferably, repair paste is provided at the gaps of the mud core. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com