Manufacturing process of sand core of precoated sand for coupler knuckle of locomotive coupler

A manufacturing process and technology of coated sand, applied in manufacturing tools, cores, molding machines, etc., can solve the problems of inability to judge whether the sand core is qualified, low core-making efficiency, sand inclusion, etc., to save waste loss and defective products Saving costs, improving productivity and quality, reducing casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

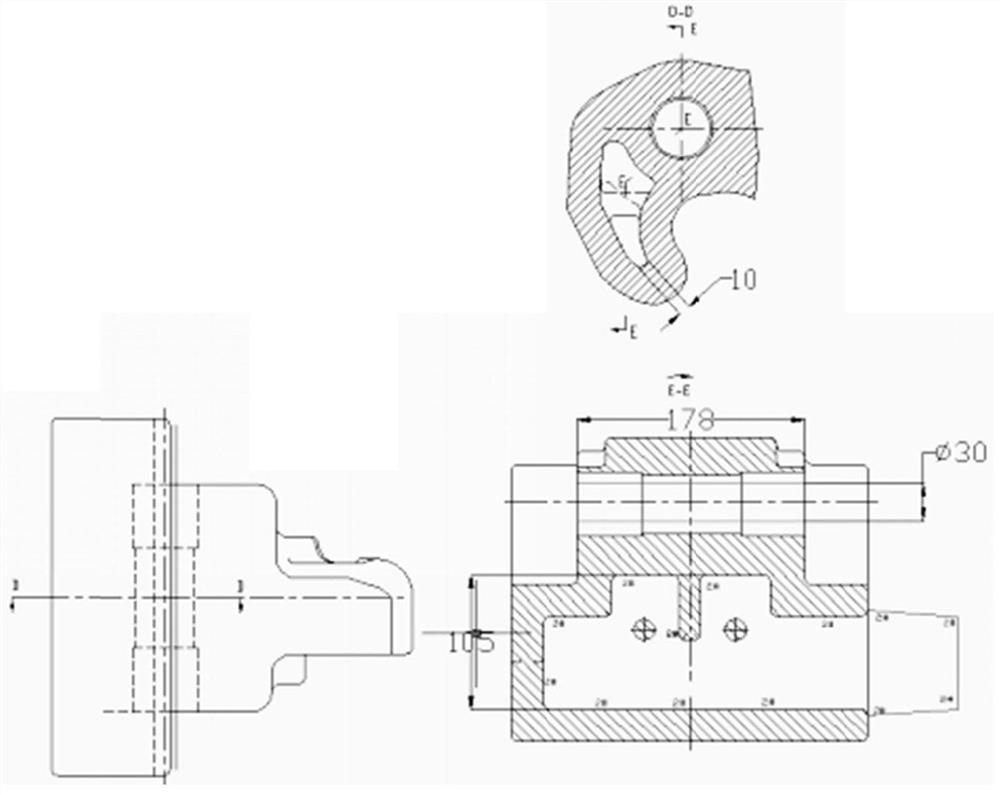

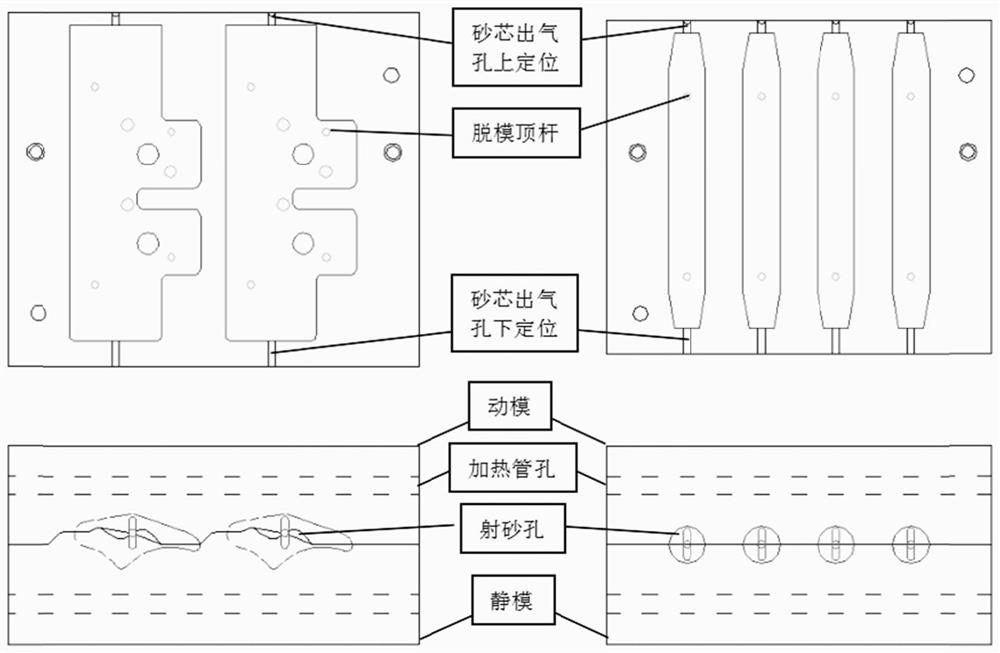

[0042] Manufacturing process of coated sand core for locomotive coupler knuckle, including:

[0043] Step 1. Determine the core making process of the hot core box: In view of the long hardening time of the alkali phenolic resin self-setting sand, the hot core box process is used in the knuckle core making method, and the core making material is coated sand;

[0044] Based on the analysis of the working condition of the knuckle sand core during pouring, the main parameter requirements of the coated sand are proposed as follows:

[0045] a. Refractoriness: ≥1600℃;

[0046] b. SiO2 content: >98%;

[0047] c. Bending strength at room temperature: ≥8.0MPa;

[0048] d. Hot bending strength: 2.5-5.0MPa;

[0049] e. Ignition loss: ≤2.5%;

[0050] f. Melting point: 90°C-110°C;

[0051] g. Particle size: 70 mesh - 140 mesh, concentration rate of adjacent three sieves ≥ 80%;

[0052] h. Average fineness: 65-75;

[0053] i. Gas output: ≤25ml / g, 1000℃±5℃, 3min.

[0054] Step 2. Des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com