Compaction-free forming iron chill

A cold iron and compaction technology, applied in the field of cold iron for casting, can solve the problems of increasing labor intensity of workers, affecting work efficiency, poor appearance quality, etc., to avoid casting flash, avoid artificial compaction, and fire defects Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

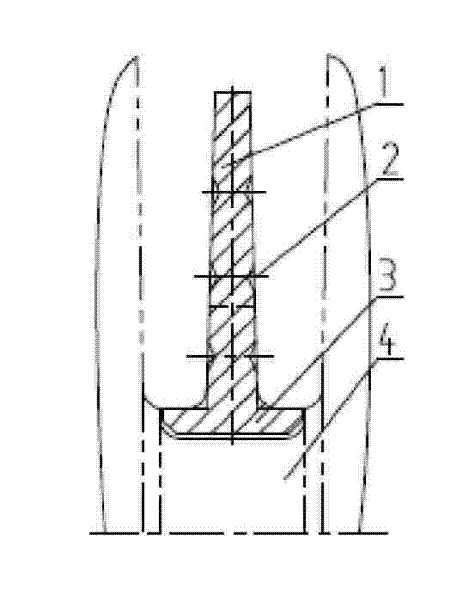

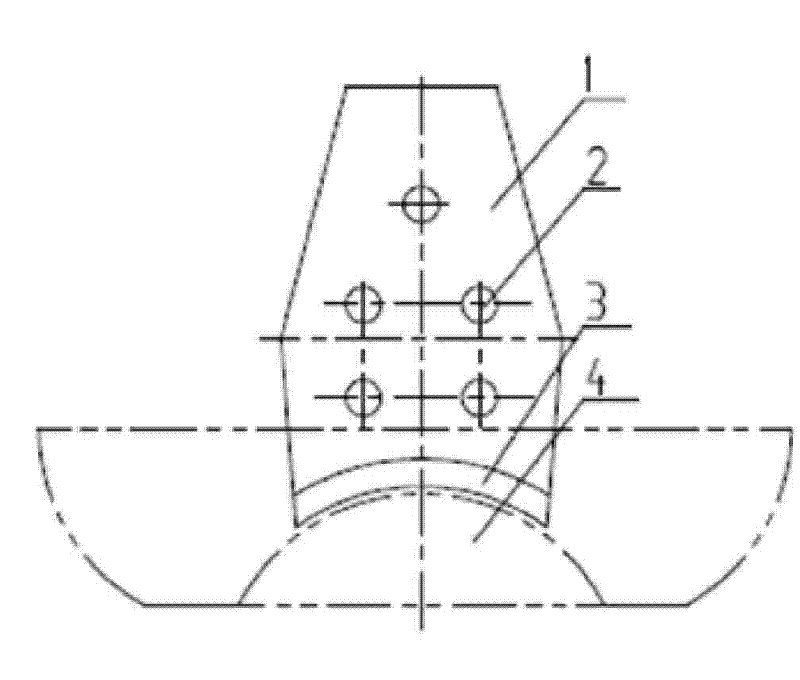

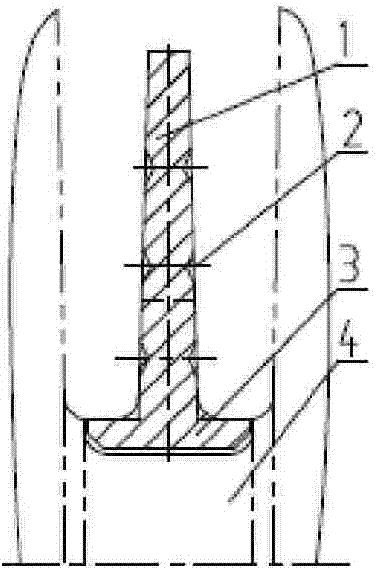

[0012] from figure 1 , figure 2 It can be seen that a non-compacting cold iron includes two parts: a tile-shaped bottom 3 and a protruding vertical part 1, and the two parts form an integrated cold iron with a "⊥" cross-section. Wherein the effect of tile forming bottom 3 is to chill the molten iron at the hot spot. The protruding vertical part 1 has a rhombus structure, and several anti-falling grooves 2 are provided on both sides thereof. The effect of protruding vertical part 1 is to increase the chilling ability of cold iron. The effect of the anti-falling groove 2 is to fix the chilled iron in the sand mold, which is not easy to come off.

[0013] The arc shape of the tile-shaped molding bottom 3 in the present invention is consistent with the shape of the contact part of the casting model 4 . The part of the casting model 4 in contact with the tile molding bottom 3 includes the boss of the casting model 4 and part of the journal. The tile-shaped bottom 3 covers 30-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com