Preparation method for controllable nitriding-physical vapor deposition (PVD) composite coating of high-speed steel tool

A technology of composite coating and high-speed steel, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of high nitrogen content in the nitriding layer, high nitrogen potential, and affecting the toughness of the cutting edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

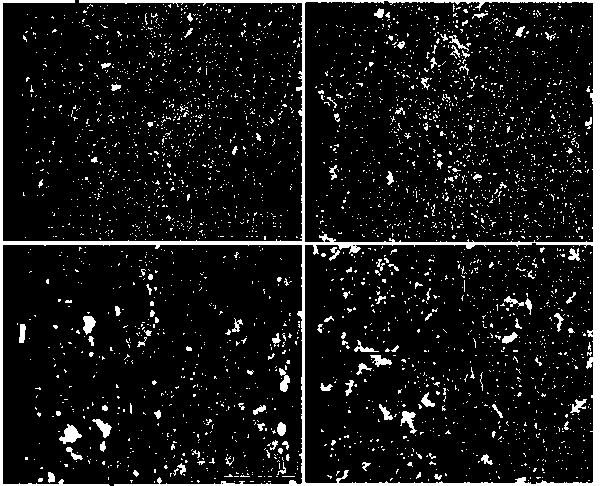

[0027] The 16mm M2 high-speed steel end mills purchased in the market are subjected to degreasing and degreasing ultrasonic cleaning, sandblasting and ultrasonic ethanol cleaning, and drying, and then put the cleaned samples into a bell-type ion nitriding furnace. Turn on the mechanical pump, pump the vacuum in the furnace to 1Pa, and then carry out glow heating with argon and hydrogen. Argon and ammonia, the flow of argon and ammonia is precisely regulated, the nitrogen potential in the furnace is controlled within 0.35, and the nitriding time is 7 minutes; 15 minutes, 20 minutes and 180 minutes. After the nitriding is completed, cool down to room temperature with the furnace to obtain the nitrided high-speed steel cutting tool. The results show that there is no compound layer in the nitriding layer of the samples in the four states, and there is a serious grain boundary structure in the sample nitriding for 180 min, and the nitrided layer is abnormally thick, while the sampl...

Embodiment 2

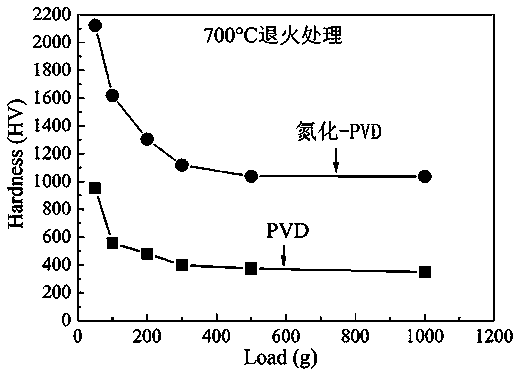

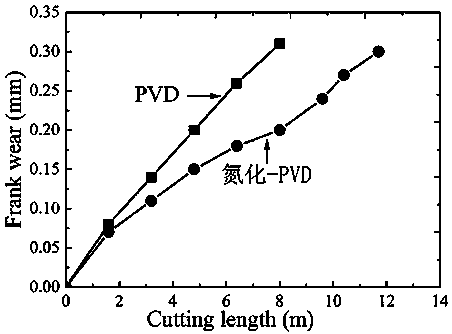

[0029] The samples with a nitriding time of 20 minutes and the unnitrided samples were selected as research materials, and the nitrided samples were prepared under the nitriding process of the case. Then, the vacuum annealing experiment was carried out on the single PVD coating sample and the low nitrogen potential precision controllable nitriding-PVD composite coating sample at 700 ° C, kept for 2 hours, and then cooled to room temperature with the furnace. Then use a microhardness tester to test the hardness of the sample surface under different loading conditions, and the test results are as follows figure 2 shown. The research results show that within the test load range, the surface hardness of the low nitrogen potential precision controllable nitriding-PVD composite coating is always higher than that of a single PVD coating. Even under a load of 1000g, the coating hardness still reaches nearly 1100HV, more The hardness of the low nitrogen potential precision controllab...

Embodiment 3

[0031] The 16mm M2 high-speed steel end mills purchased in the market are subjected to degreasing and degreasing ultrasonic cleaning, sandblasting and ultrasonic ethanol cleaning, and drying, and then put the cleaned samples into a bell-type ion nitriding furnace. Turn on the mechanical pump, pump the vacuum in the furnace to 1Pa, and then carry out glow heating with argon and hydrogen. Argon and ammonia, the flow rate of argon and ammonia is precisely regulated, the nitrogen potential in the furnace is controlled within 0.35, and the nitriding time is 7min, 15min, 20min and 180min. After the nitriding is completed, cool down to room temperature with the furnace to obtain the nitrided high-speed steel cutting tool.

[0032] Put the nitrided high-speed steel tool into alcohol and acetone, clean it with ultrasonic waves for 30 minutes, then dry the cleaned sample with an air gun and place it on the substrate holder in the furnace cavity. Turn on the mechanical pump and the mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com