Manual core box core ejecting mechanism and core making method

A technology of core boxes and top cores, applied in the direction of cores, manufacturing tools, metal processing equipment, etc., can solve the problems that affect the quality and efficiency of core making, increase labor costs, increase labor intensity, etc., and achieve low mold cost, The effect of simple structure and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

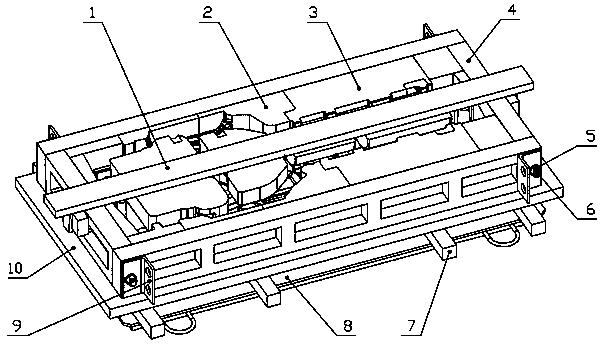

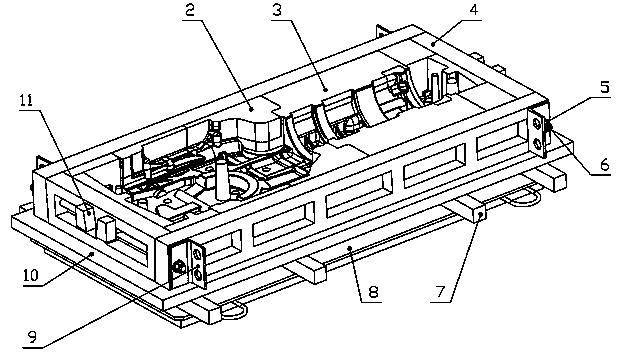

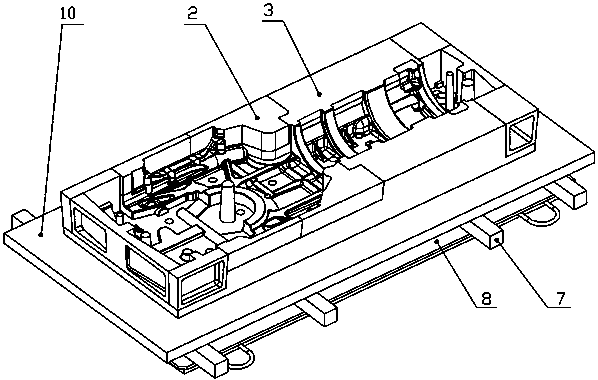

[0028] Embodiment 1, a manual core box top core mechanism, including sand reducing block, core box cavity block assembly, bottom mold, core box wooden frame assembly, nuts, bolts, top core spacer, top core plate, hanging Ears, core box substrate, sand reducing block positioning block and top core rod. The core box wooden frame assembly is provided with a sand reducing block positioning block for positioning the sand reducing block mounted on the core box wooden frame assembly. A top core spacer is arranged between the core box substrate and the top core plate, the top core spacer is removed, the core box substrate and the bottom mold fall on the top core plate under the action of gravity or external force, and the sand core Remove the bottom mold. The core box cavity block components are sequentially installed on the bottom mold to form the entire sand core cavity. The bottom mold is fixed on the core box base plate, and the top core rod hole is drilled together. The core bo...

Embodiment 2

[0034] Example 2, such as Figure 1 to Figure 4 As shown, a manual core box top core mechanism includes a sand reducing block, a core box cavity block assembly, a bottom mold, a core box wooden frame assembly, nuts, bolts, top core spacers, top core plates, and lifting lugs , Core box substrate, sand reducing block positioning block, top core rod. The feature is that the core box wooden frame component (4) is provided with a sand reducing block positioning block (11) for positioning the sand reducing block (1) mounted on the core box wooden frame component (4). A top core spacer (7) is provided between the core box substrate (10) and the top core plate (8), the top core spacer (7), the core box substrate (10) and the bottom mold ( 3) When it falls on the top core plate (8) under its own gravity or external force, the sand core is separated from the bottom mold (3). The core box cavity block assembly (2) is sequentially installed on the bottom mold (3), thereby forming the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com