Ventilation cooling sand core for casting cylinder jacket of diesel engine and manufacturing method thereof

A technology of ventilation cooling and cylinder liner, which is used in casting molding equipment, molds, cores, etc., can solve the problems of increasing core-making workload, fluctuating cylinder liner quality, and difficulty in compacting molding sand, so as to improve the core-making process. Efficiency, reduce production cost, stabilize the effect of cylinder liner quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

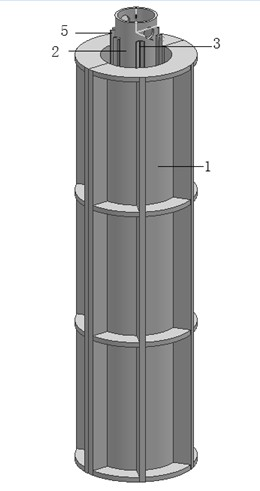

[0054] Please see first figure 1 , figure 1 It is a structural schematic diagram of the sand core used for casting ventilation and cooling of diesel engine cylinder liners according to the present invention. As shown in the figure, a sand core for casting ventilation and cooling of a diesel engine cylinder liner consists of three parts: a core shell 1, a core bone 2 placed in the core shell 1, and a ventilation rope 3.

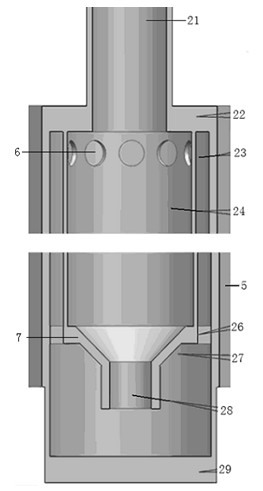

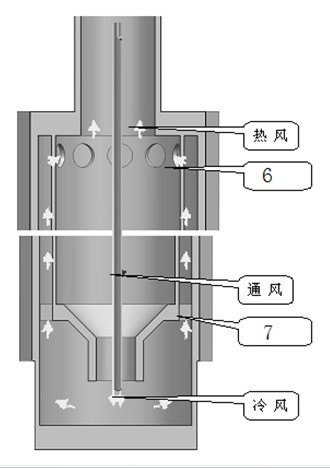

[0055] Such as figure 2 As shown, the core frame 2 includes a sheathed inner steel pipe 24 and a longer outer steel pipe 23, and the upper ends of the inner steel pipe 24 and the outer steel pipe 23 are vertically fixed together with the first circular steel plate 22. The upper end of the inner steel pipe 24 is provided with a plurality of upper ventila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com