Low-pressure casting method and device for thin-wall complex aluminum alloy gearbox shell

A low-pressure casting and gearbox technology, which is applied to the low-pressure casting method and device of thin-walled complex aluminum alloy gearbox casing, and the field of casting method and device, can solve the problems of large difference in wall thickness of castings, poor forming, complex structure, etc. Reduced weight, increased area, increased heating area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

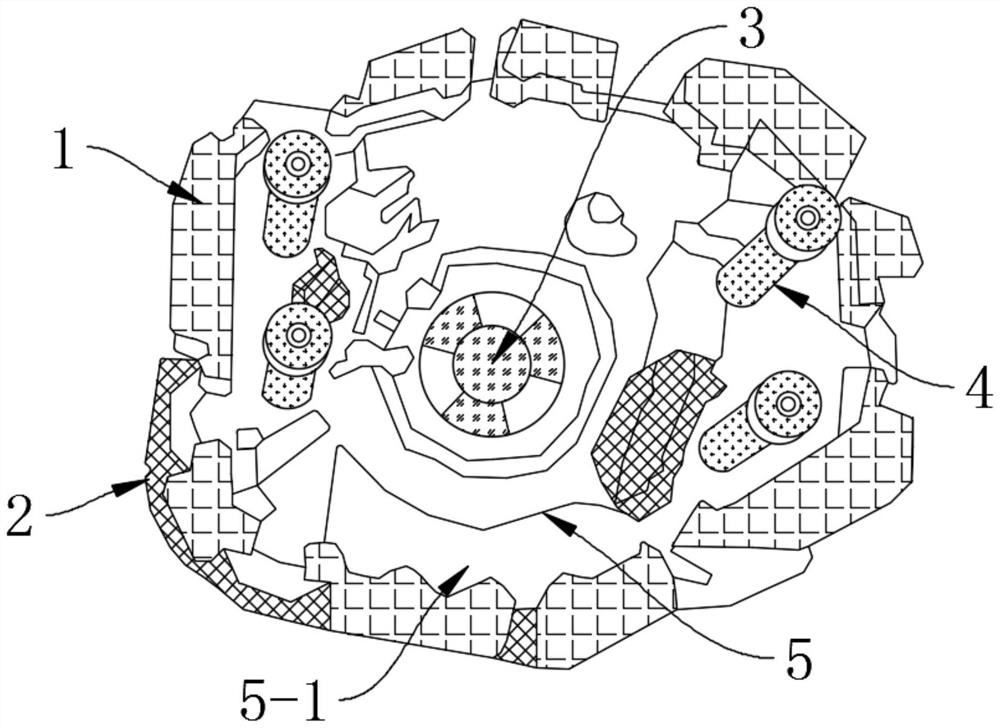

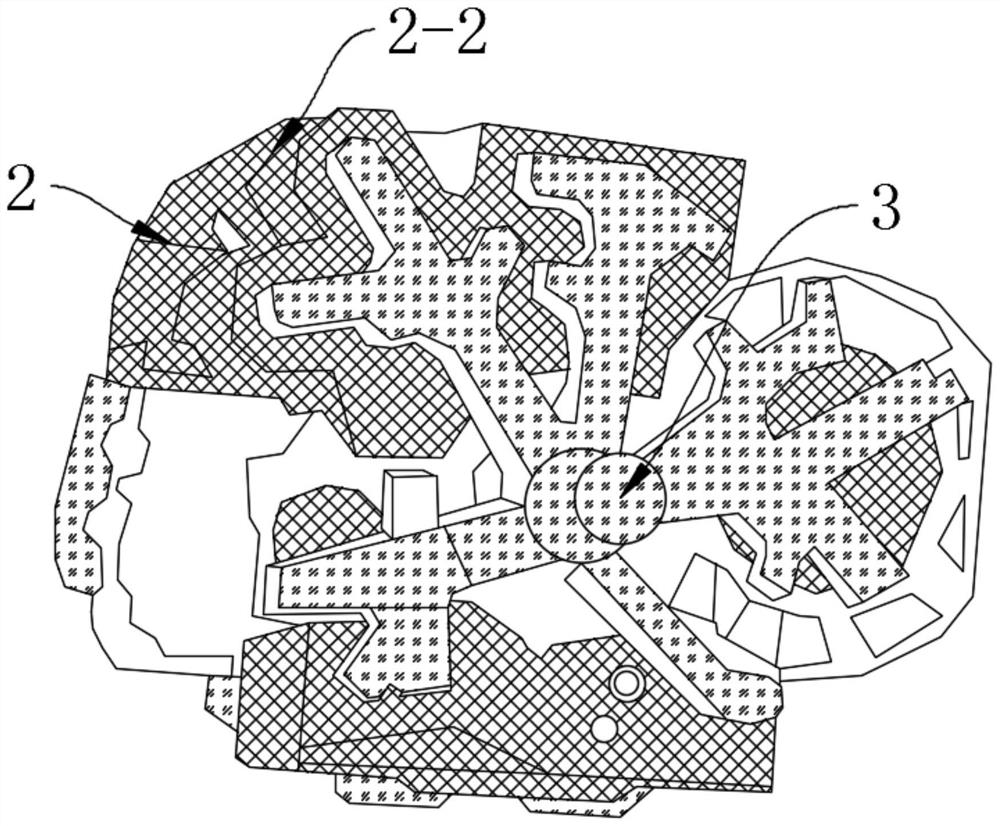

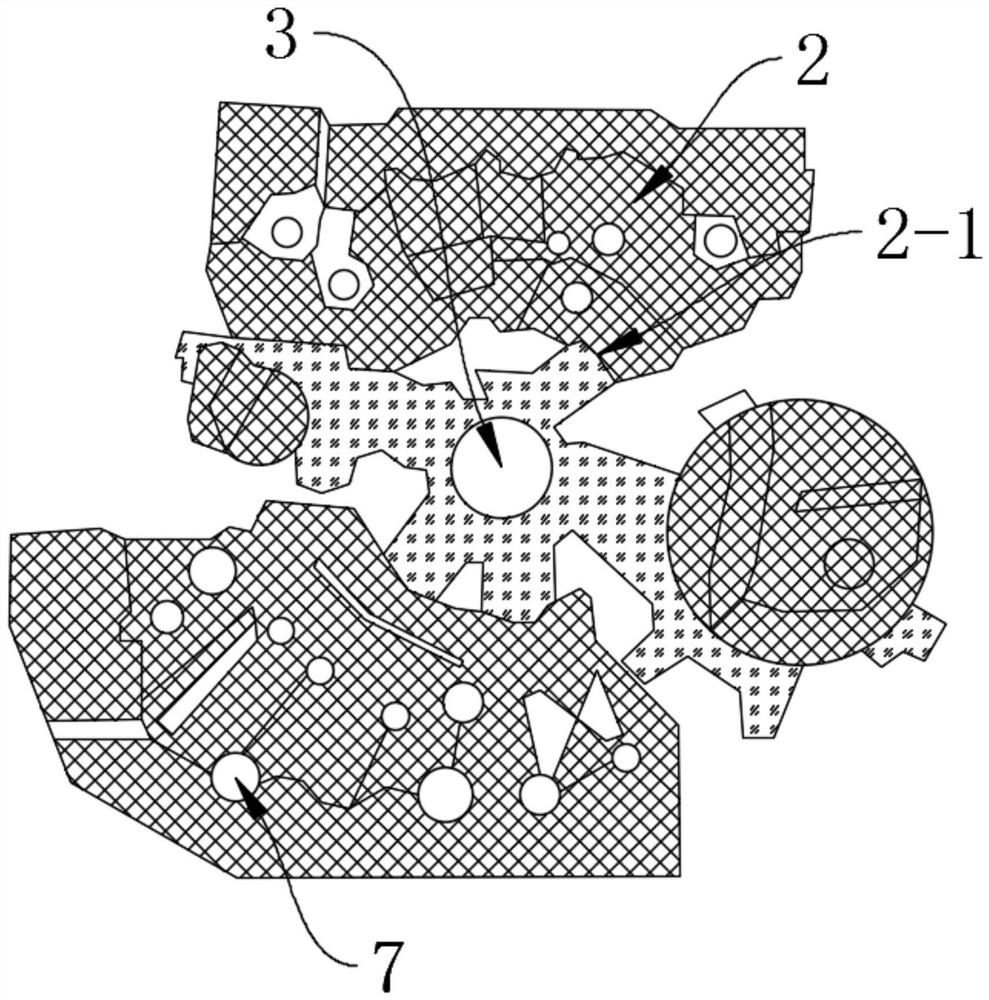

[0043] A low-pressure casting device for a thin-walled complex aluminum alloy gearbox housing, including a riser 1, a sand core 2, a gate 3 and a core puller 6, a cylindrical feeding channel 7 is opened on the sand core 2, and a Inner runner 3-1, the inner runner 3-1 is distributed along the shape of the gate 3, through the inner runner designed on the gate 3, the problem of shrinkage and porosity at the parts with large wall thickness on the end face of the casting gate is solved, The gate 3 and the sand core 2 are connected through the cooperation of the cylindrical feeding channel 7 and the inner runner 3-1, and the inner runner 3-1 communicates with the bolt column 5-1 of the casting 5.

[0044] The core pulling 6 is set on the outer side of the gate 3 and the sand core 2, the core pulling 6 is connected with the external push hydraulic cylinder, the upper mold, the lower mold, the core pulling 6, the gate 3, the riser 1 and the sand core 2 together form a casting 5 (upper...

Embodiment 2

[0056] A low-pressure casting method for a thin-walled complex aluminum alloy gearbox housing, comprising the following steps:

[0057] 1) Assembly and preheating of the casting device, the upper mold, the lower mold, the core 6 and the sand core 2 of the casting device are assembled, the upper mold and the lower mold of the mold are fixed on the 800 kg low-pressure casting machine, and the core is pulled 6 Installed on the guide rails around the lower mold, preheat the upper mold, lower mold and core-pulling (6) of the mold before casting. Gate 1, gate 3 and casting 5 are all formed by the cooperation of the alloy stock solution through the mold and sand core 2. Molding with cooperation;

[0058] 2) Raw material ratio, melting and purification treatment, select the corresponding raw materials according to the actual needs, mix the raw materials after mixing, then bake the aluminum furnace, and then put the prepared alloy raw materials into the aluminum furnace for melting ,...

Embodiment 3

[0062] A low-pressure casting method for a thin-walled complex aluminum alloy gearbox housing, comprising the following steps:

[0063] 1) Assembly and preheating of the casting device, the upper mold, the lower mold, the core 6 and the sand core 2 of the casting device are assembled, the upper mold and the lower mold of the mold are fixed on the 800 kg low-pressure casting machine, and the core is pulled 6 Installed on the guide rails around the lower mold, preheat the upper mold, lower mold and core-pulling (6) of the mold before casting. Gate 1, gate 3 and casting 5 are all formed by the cooperation of the alloy stock solution through the mold and sand core 2. Molding with cooperation;

[0064] 2) Raw material ratio, melting and purification treatment, select the corresponding raw materials according to the actual needs, mix the raw materials after mixing, then bake the aluminum furnace, and then put the prepared alloy raw materials into the aluminum furnace for melting ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com